Method for assembling tracks of permanent magnetism in use for high-temperature superconductor magnetic suspension vehicle

A technology of high-temperature superconducting and assembly methods, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of low installation efficiency, alignment, difficulty in approaching, and low efficiency, and achieve the effects of convenient operation, firm and reliable fixation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

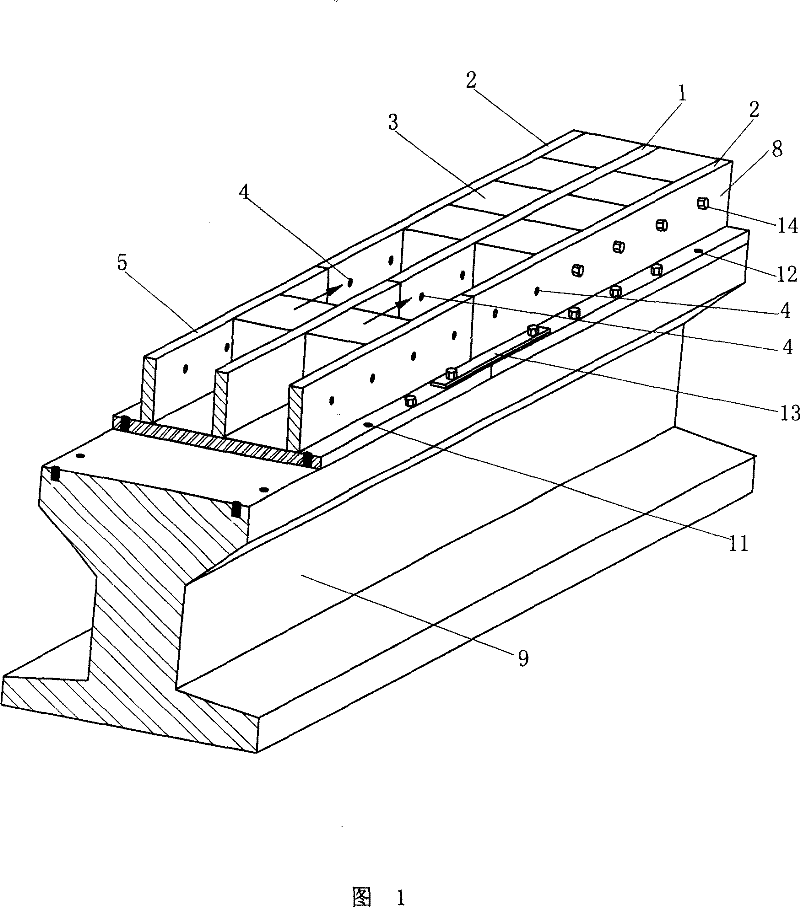

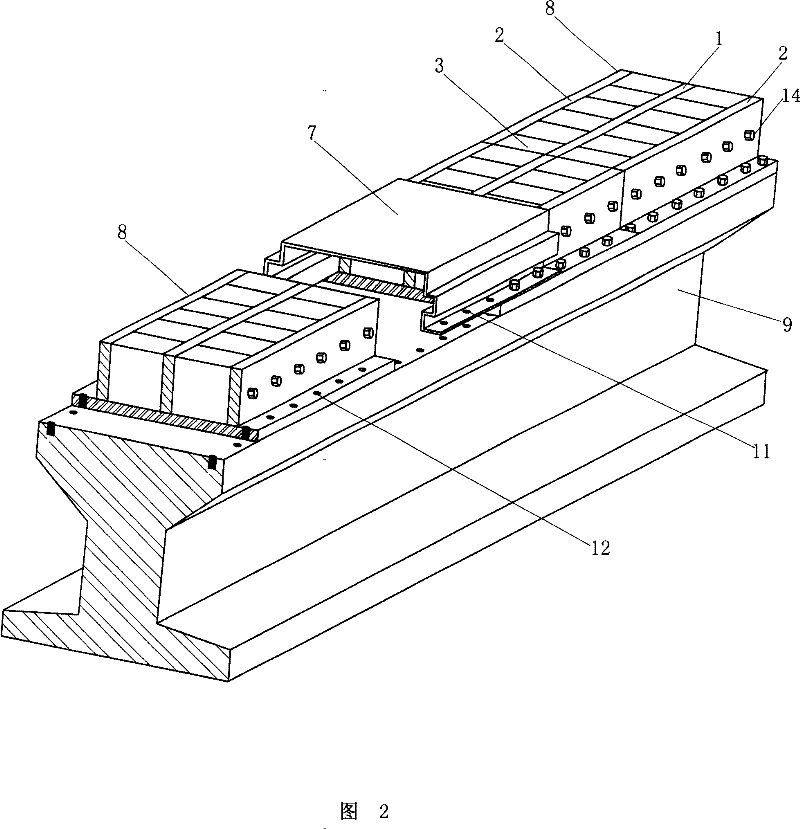

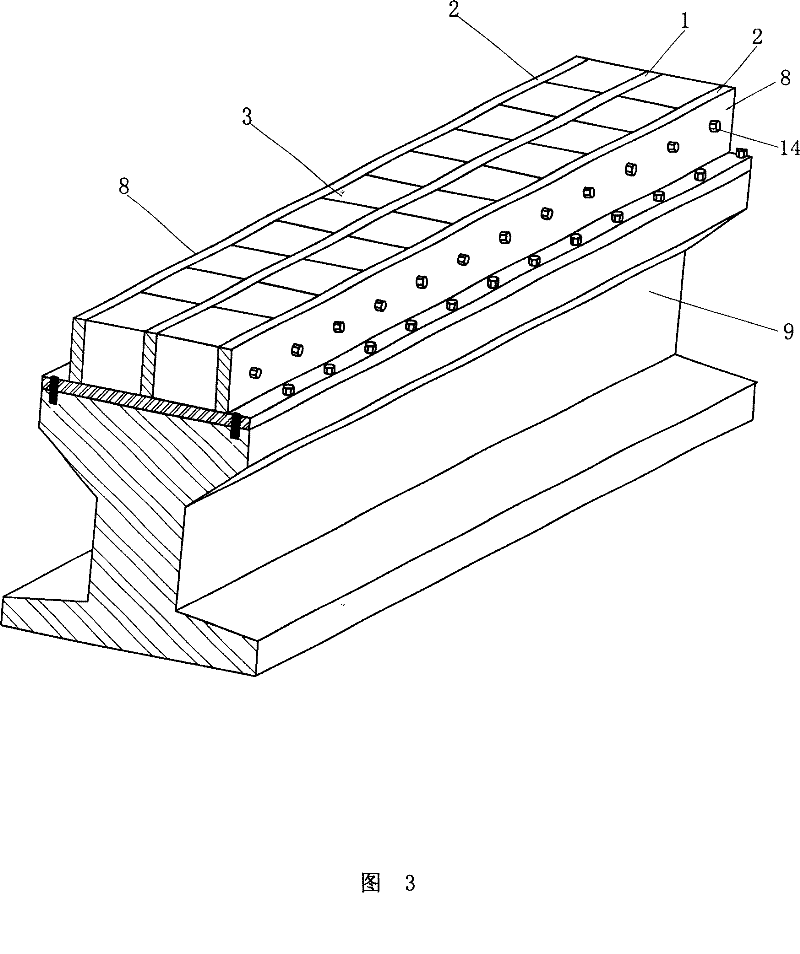

[0025] figure 1 , 2 Shown, a kind of specific embodiment of the present invention is: a kind of assembling method of permanent magnet track for high-temperature superconducting maglev vehicle, is made up of following steps:

[0026] a. Manufacture of magnetic pole gathering frame and opening of positioning holes: fix the middle magnetic gathering pole 1 and both side magnetic gathering poles 2 on the bottom plate; set up multiple horizontally aligned positioning positions on the middle magnetic gathering pole 1 and both sides of magnetic gathering poles 2 according to the predetermined positioning positions Hole 4 constitutes the pole-gathering frame of the track unit 8; each permanent magnet block 3 to be loaded into the pole-gathering frame is horizontally provided with a through positioning hole 4, and the position of the positioning hole 4 must make the permanent magnet block 3 be installed as scheduled After the position is installed in the magnetic pole gathering frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com