Bidirectional tensile tester

A test device and biaxial stretching technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex structure, expensive price, inaccurate data, etc., and achieve the effect of light structure, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

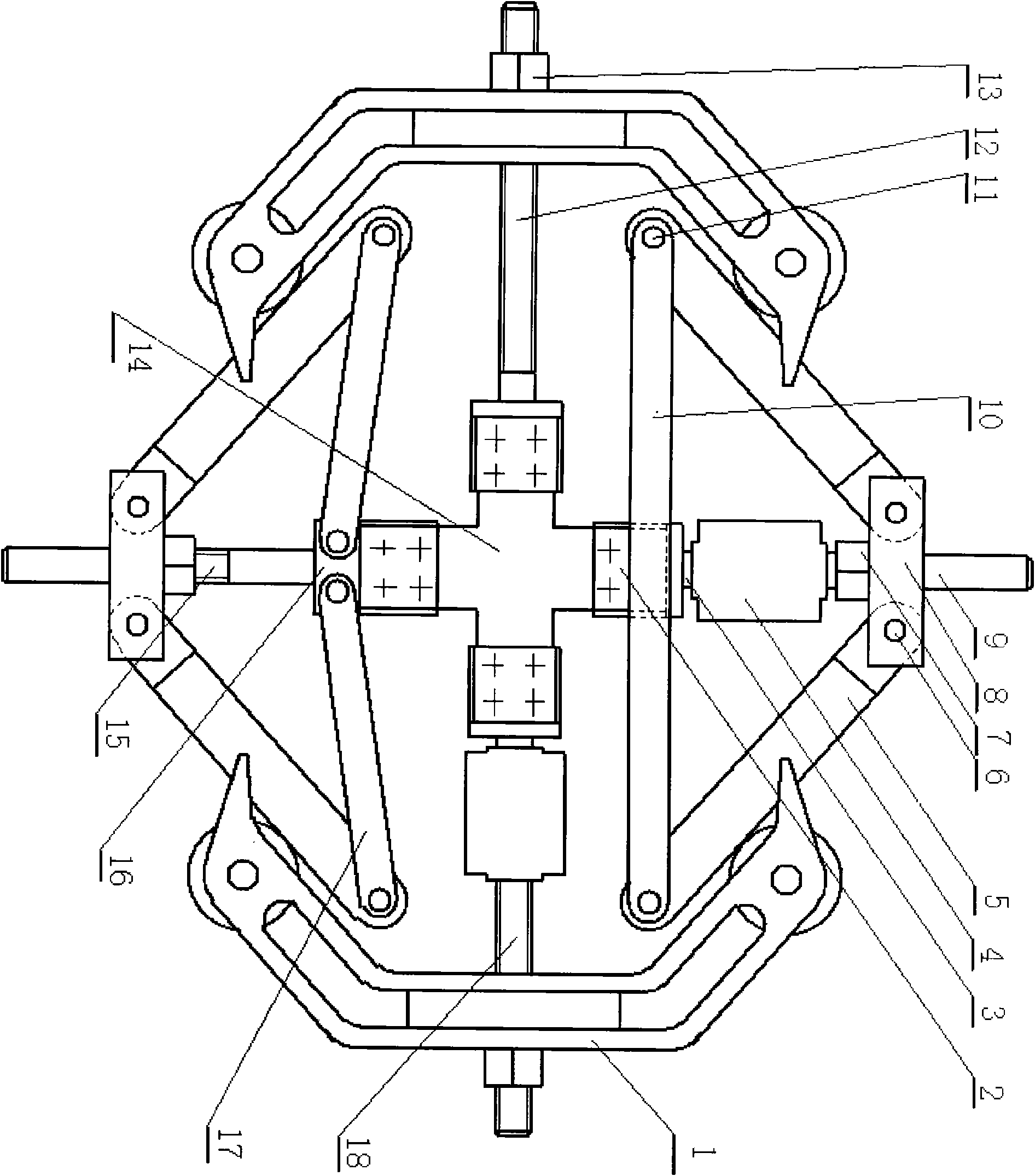

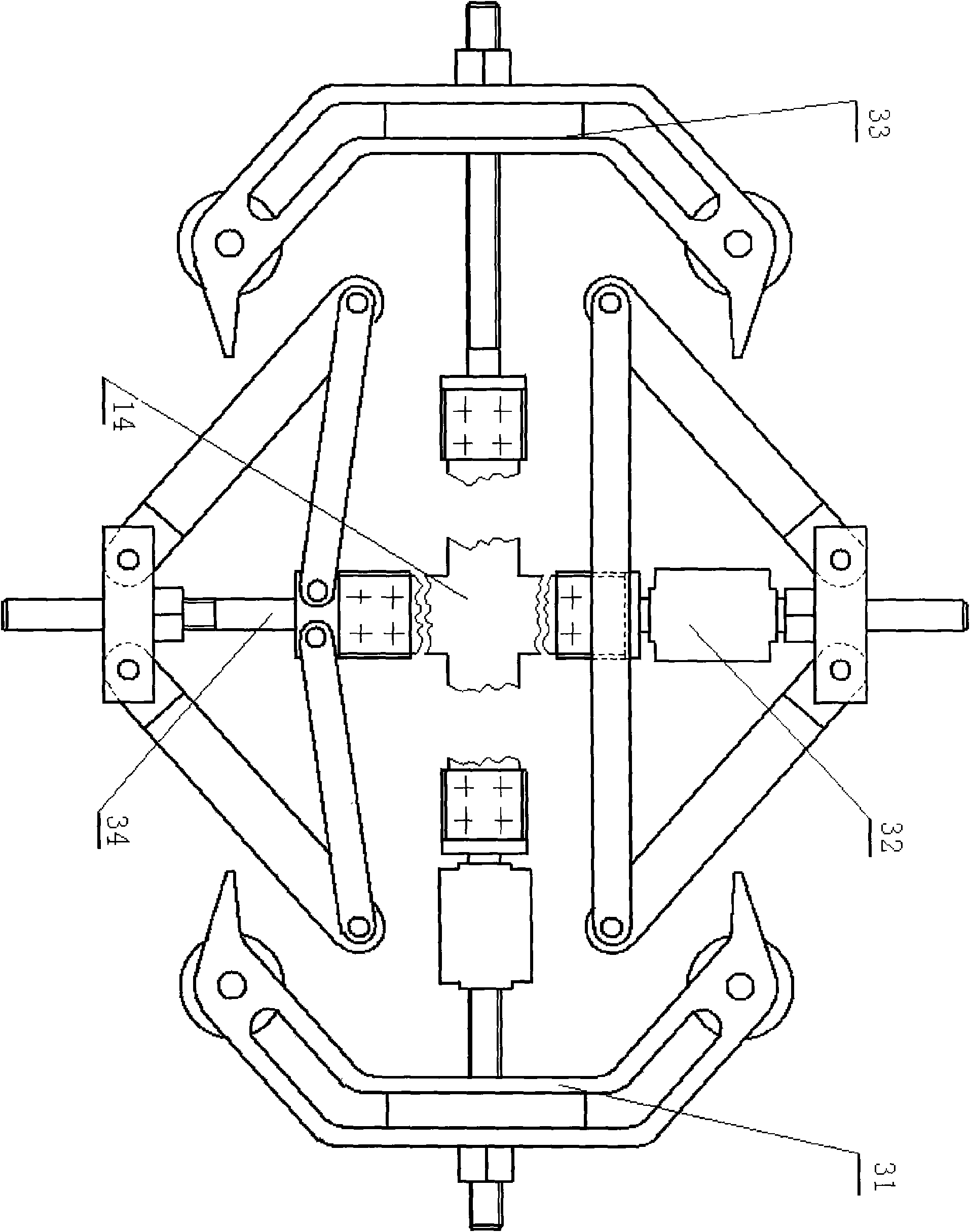

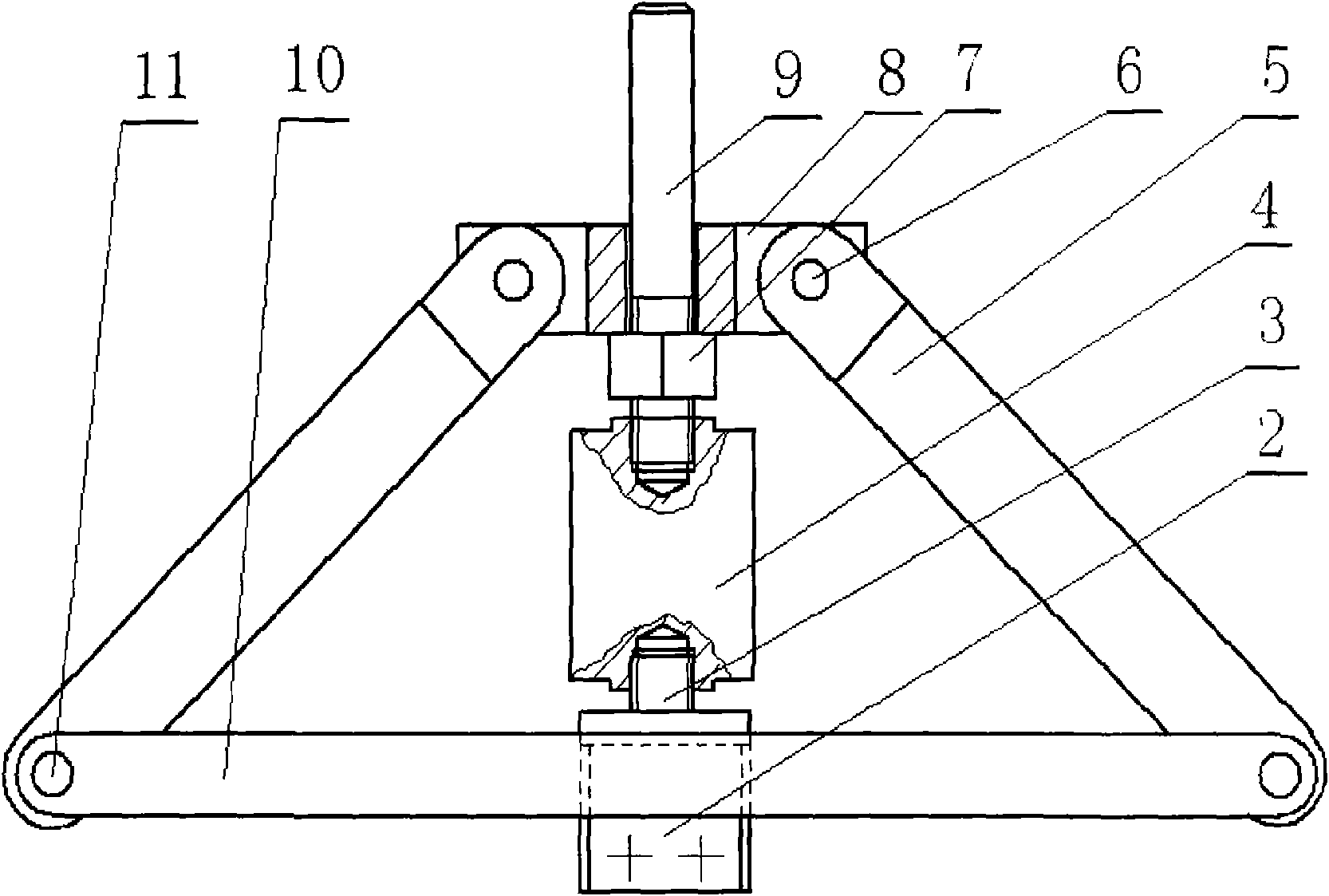

[0027] This embodiment is a bidirectional tensile testing device for a cross-shaped test piece, and includes a fixed force component mechanism 32, an adjustable force component mechanism 34, a measurable force transmission mechanism 31, and an unmeasurable force transmission mechanism 33. Place the cross-shaped test piece 14 in the center of the device, and the fixed force component mechanism 32, the adjustable force component mechanism 34, the measurable force transmission mechanism 31 and the unmeasurable force transmission mechanism 33 pass through the test piece chuck and the cross shape respectively. The four directions of the test piece 14 are fixedly connected, and the cross-shaped test piece 14 is stretched. The fixed force component mechanism 32 and the adjustable force component mechanism 34 are located on the vertical axis of the cross-shaped specimen and are symmetrical to the specimen; the measurable force transmission mechanism 31 and the unmeasurable force transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com