Method for detecting capacitive type touch-control device

A technology of capacitive touch and detection method, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as affecting the performance of the application side and reducing the image acquisition speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

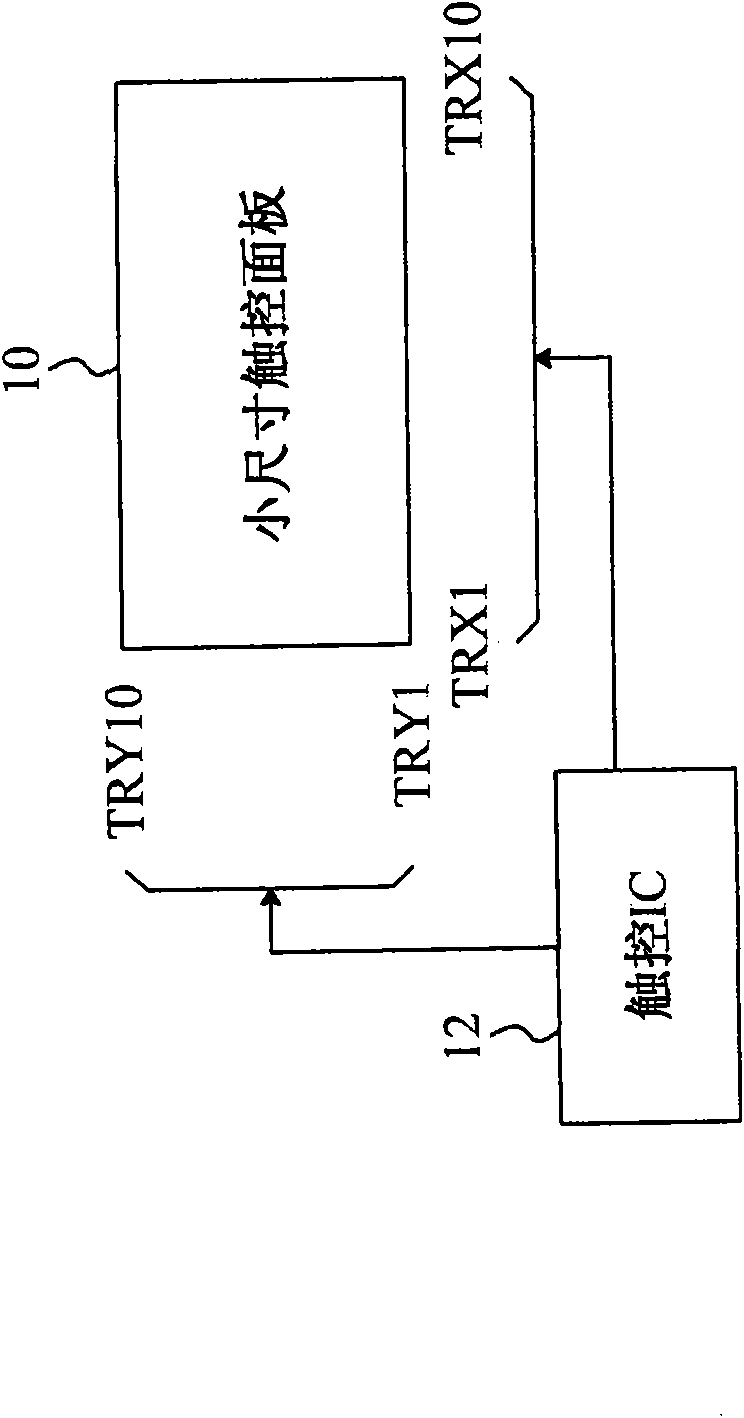

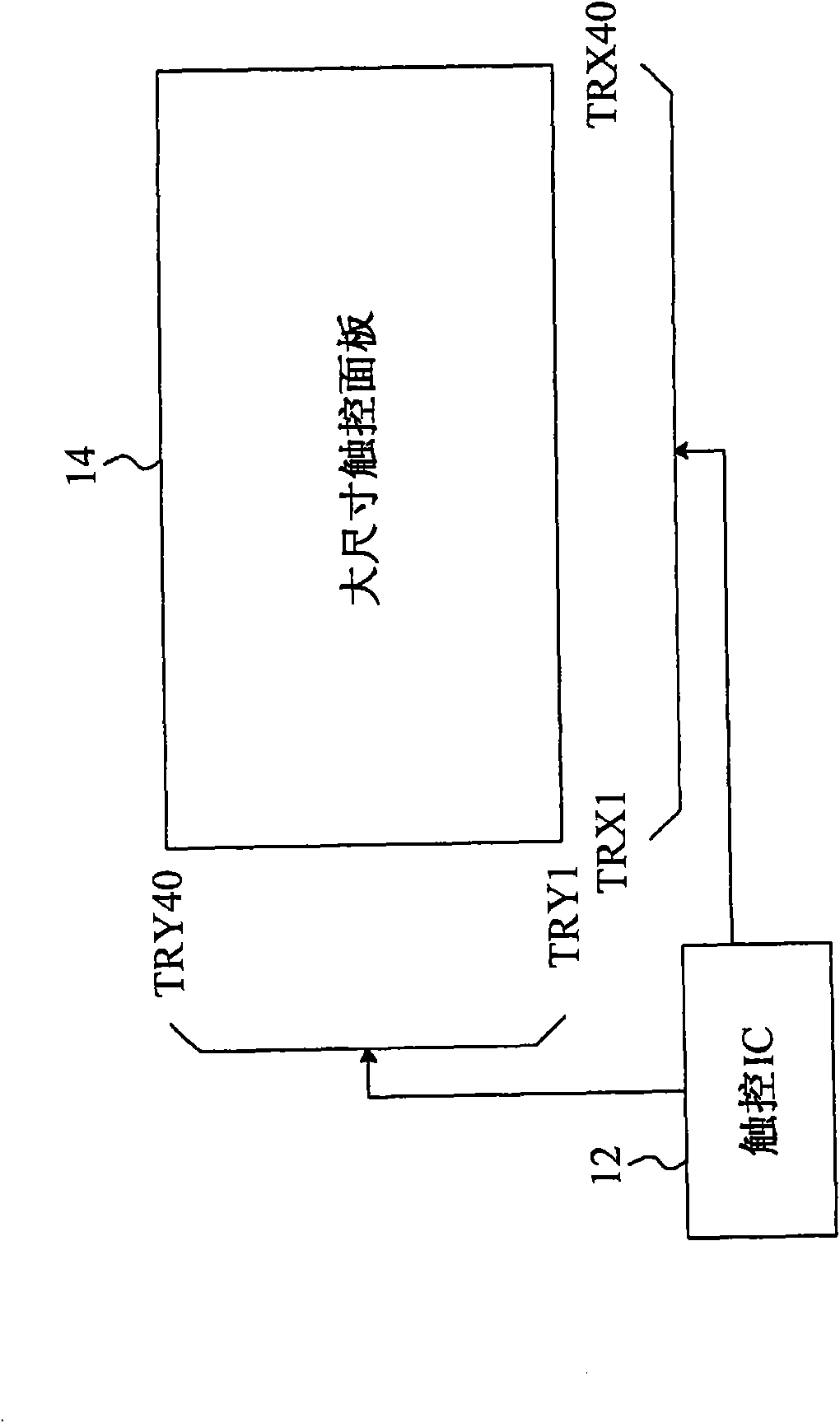

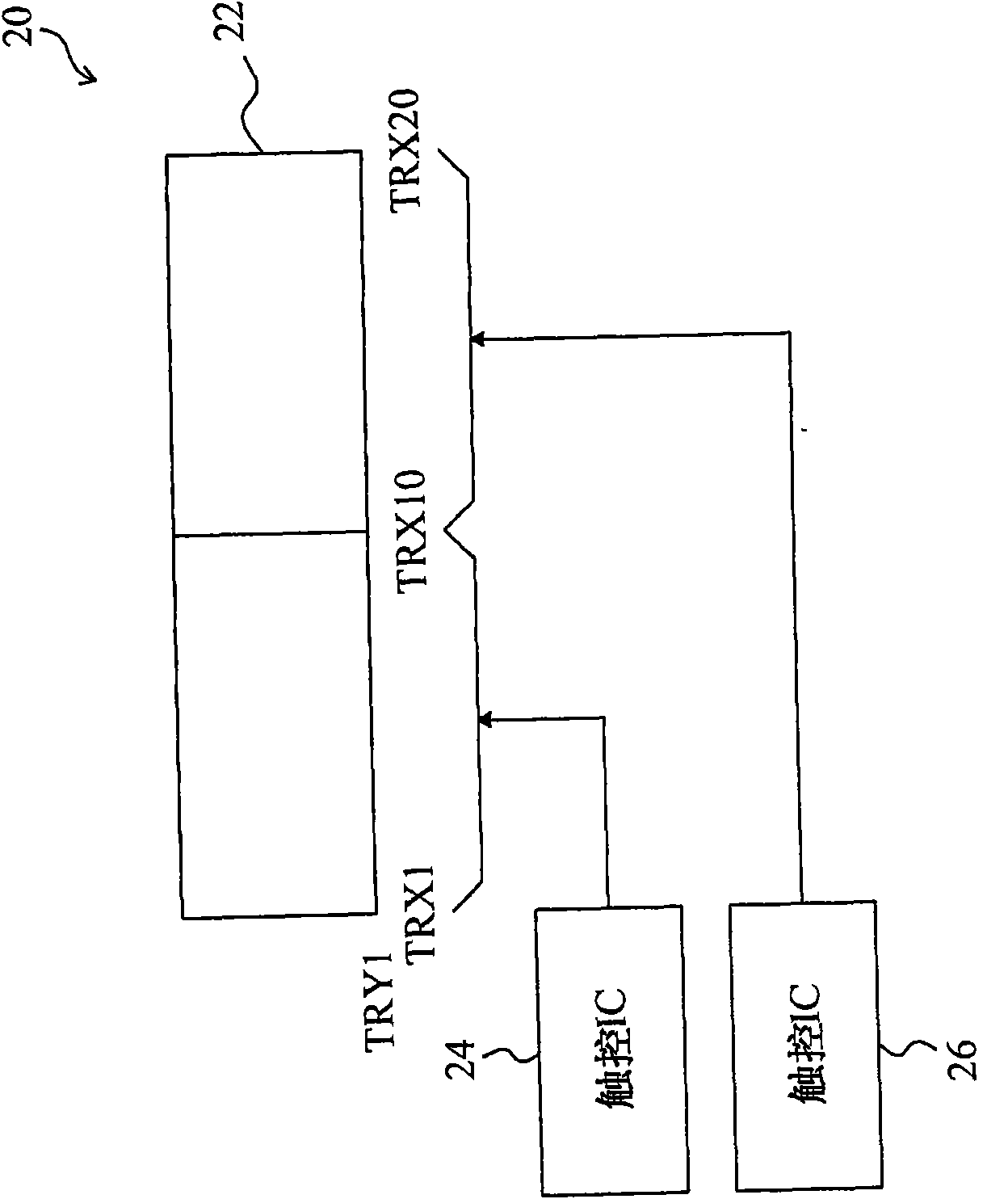

[0026] image 3 It shows a capacitive touch device 20 that uses more than two AI-type array capacitive touch ICs to scan a touch panel. Figure 4 show image 3 A partial enlargement of the . In the capacitive touch device 20 , the touch IC 24 scans the sensing lines TRX1 to TRX10 in the touch panel 22 , and the touch IC 26 scans the sensing lines TRX11 to TRX20 in the touch panel 22 . Since the capacitive touch device 20 can use multiple AI-type array capacitive touch ICs to scan the touch panel at the same time, it not only has a multi-finger touch function but also has a good image capture speed when applied to a large-size panel. In the detection method of the capacitive touch IC of the small-sized touch panel, generally two sensing lines are selected at the same time to charge and discharge the capacitance to obtain the analog-to-digital conversion (Analogy Digital Convert; ADC) value of the two sensing lines. Then use the ADC values of the two sensing lines to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com