Fluid supply device for spraying system

A fluid supply device and surface spraying technology, applied in the field of spraying systems, can solve the problems of easy failure of system stability, high technical cost and high cost, achieve convenient and rapid contact, reduce installation cost and operating cost, and replace quickly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The invention will be described in detail below through the embodiments of the invention and the accompanying drawings.

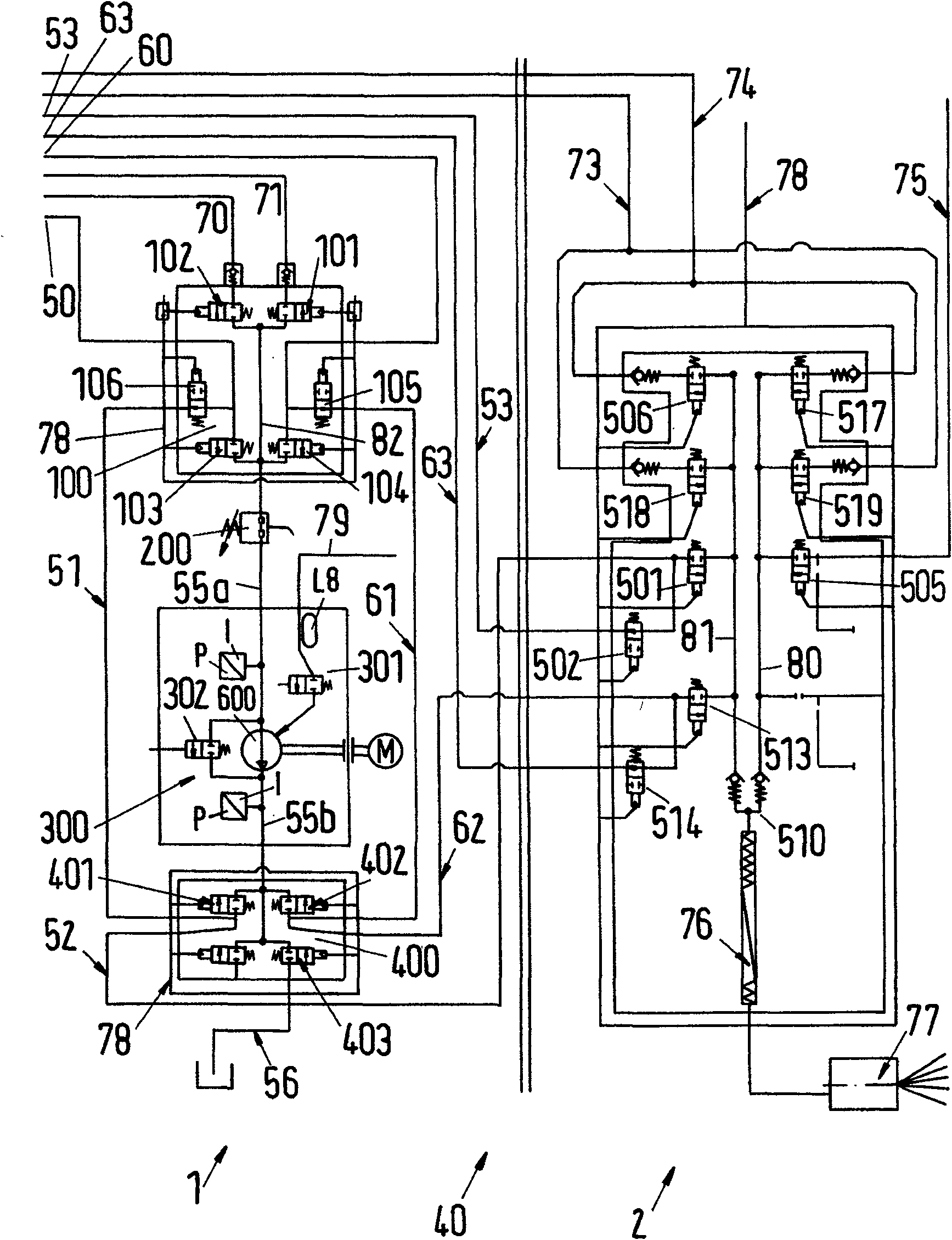

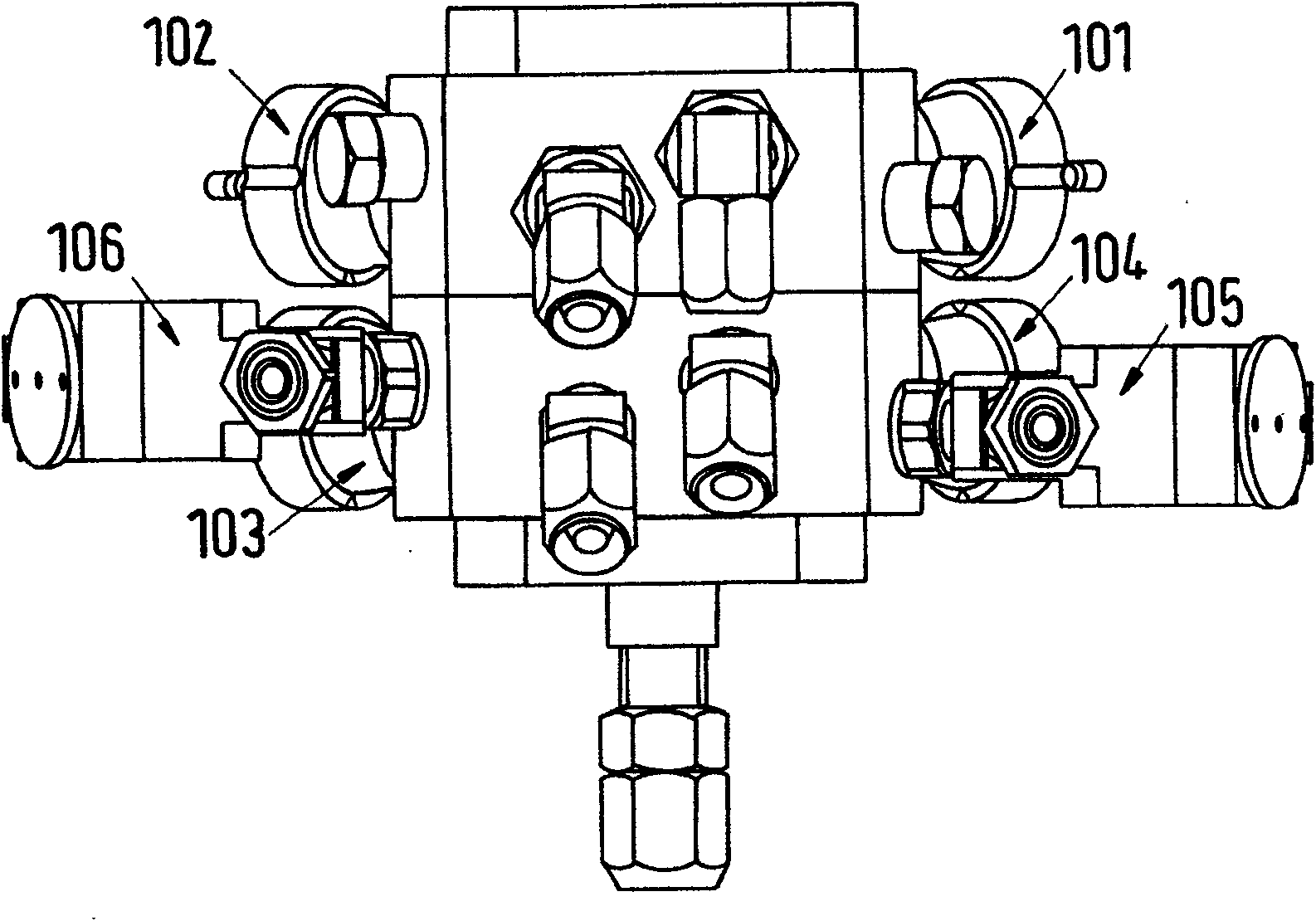

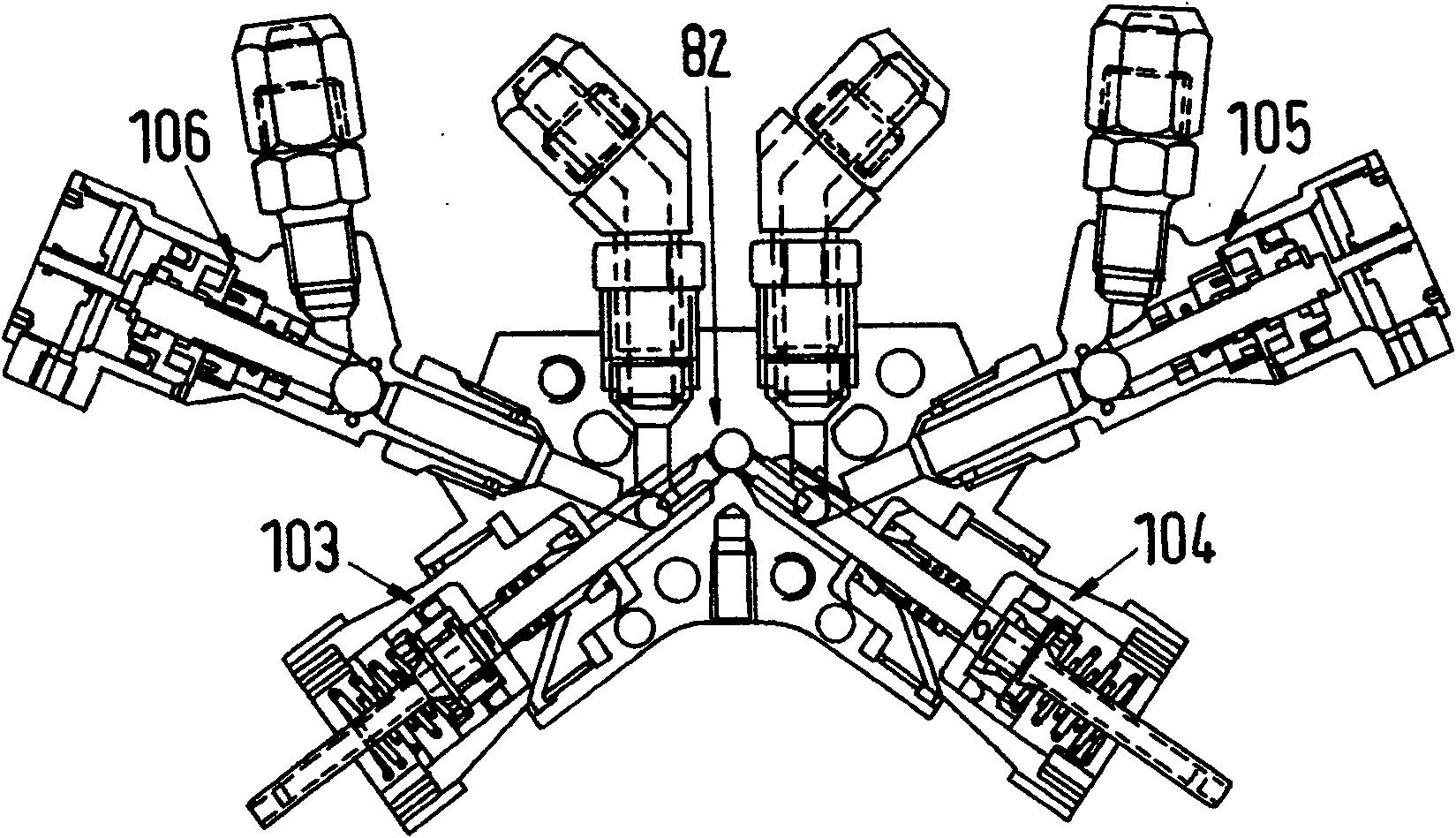

[0073] figure 1 In is a typical fluid supply arrangement for a paint spraying system 40 using two paints. The device consists of two modules 1, 2, wherein the first module 1 is mounted on the wall of the spray booth and the second module 2 is mounted on a robot or automatic painting device. The two paints enter the first module 1 through two independent paint supply lines 50, 60, and pass through the paint valves 103, 104 arranged there in the first paint changing unit 100, and are sent to the same arrangement in the second Circulation valves 105 , 106 in a paint changing unit 100 . At the outlets of the circulation valves 105, 106, there are pipelines 51, 61 for paint circulation, respectively. These lines end at the paint valves 401 , 402 of the second paint change unit 400 . The paint can likewise pass through the paint valves 401 , 402 and vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com