Engine material rest

A technology for engines and material racks, which is applied in the field of material racks for placing engines, and can solve problems such as inability to fully fix the engine, inaccurate positioning of the positioning device, and inability to install the engine, etc., and achieve the effects of labor-saving operation, simple device, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

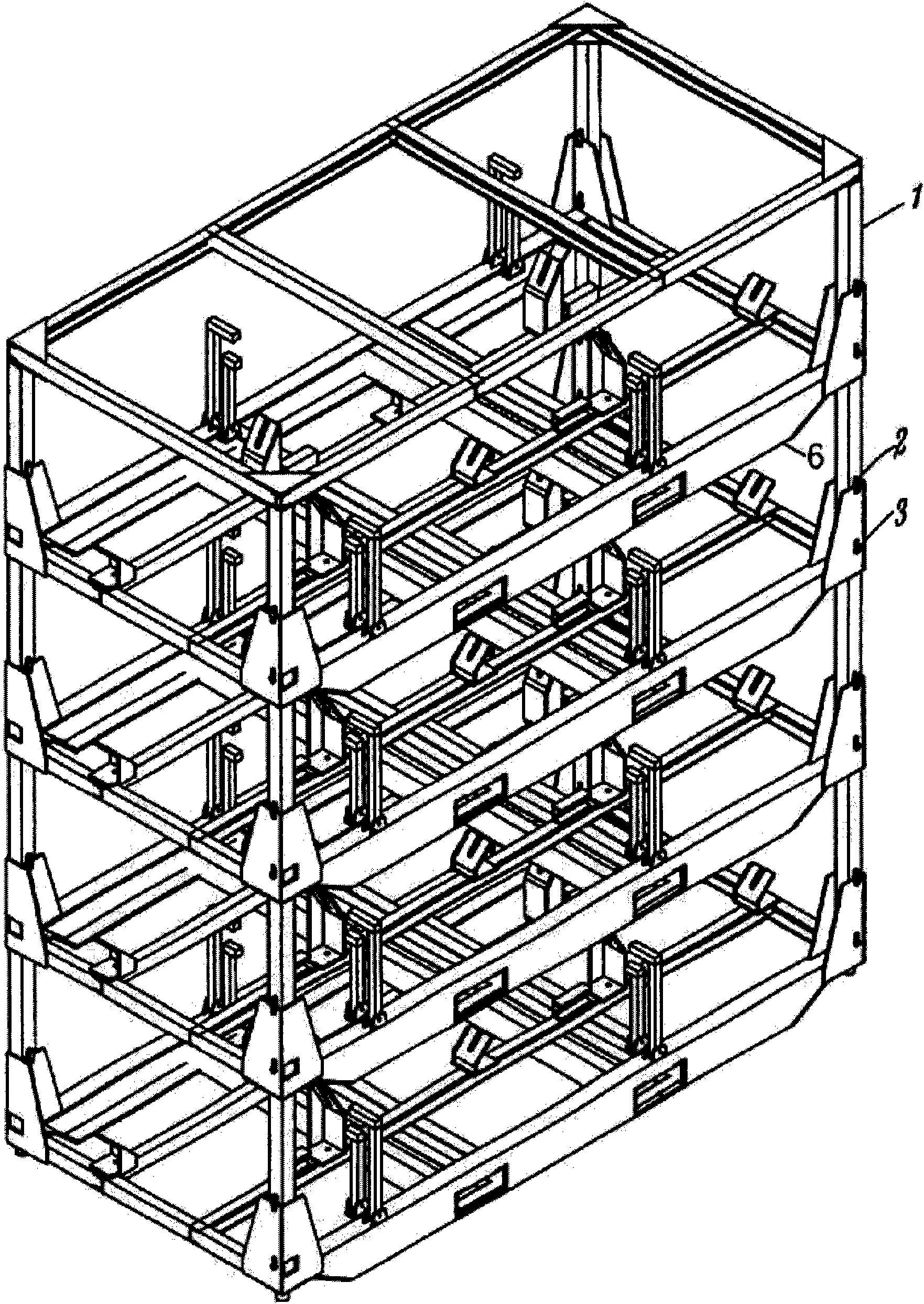

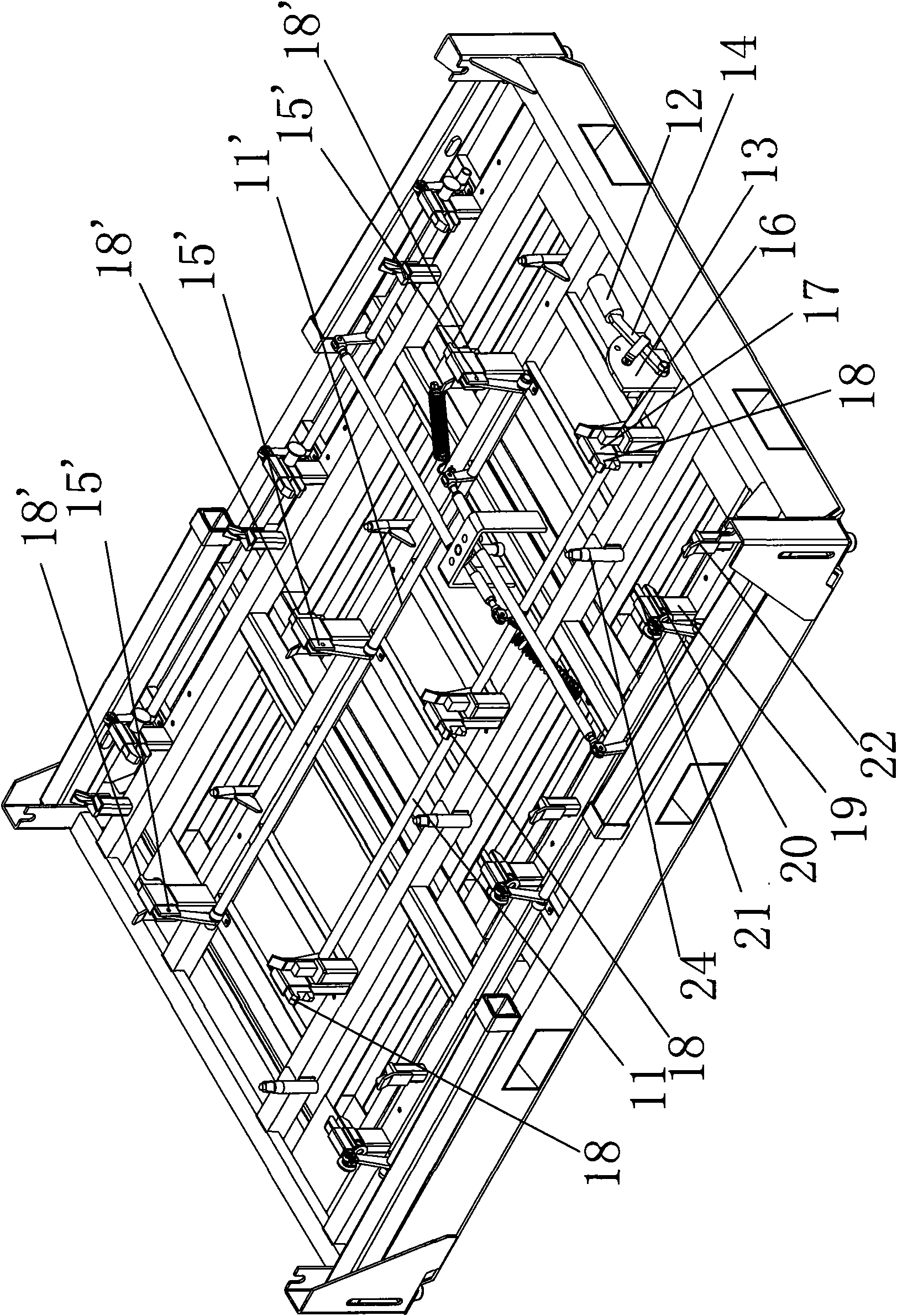

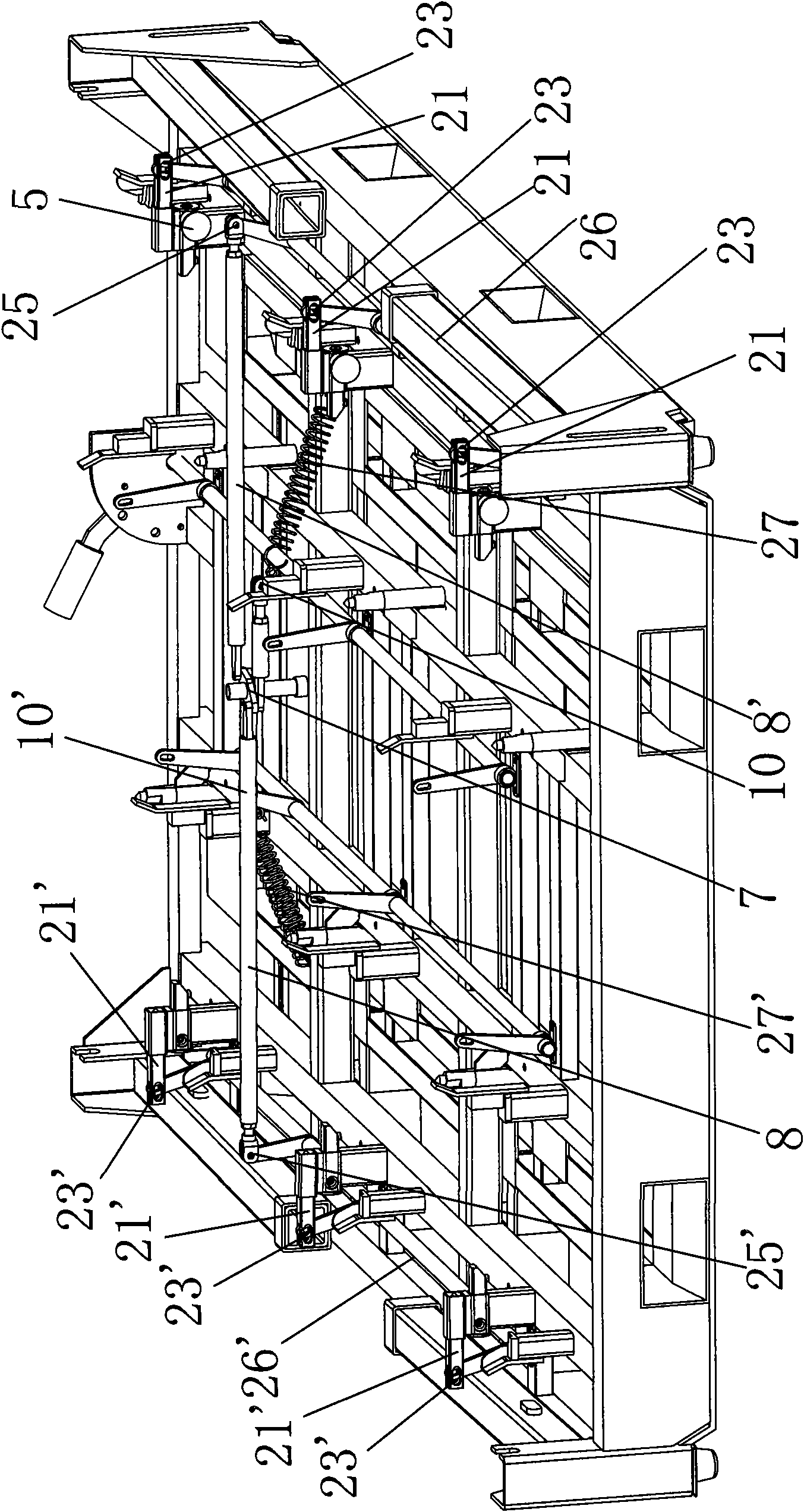

[0029] Such as figure 2 , Shown in 3, the present embodiment includes a rack body 1, which is provided with 6 engine placement stations. All comprise two fixed support frames 16,22 ( Figure 7 ) and a fixed positioning pin 24 ( Figure 8 );Such as Figure 7 As shown, it also includes a movable double pressure block positioning frame 17, on which a movable double pressure block 18 is movably arranged, and the movable double pressure block is arranged up and down to adapt to engine positioning of different sizes and specifications; as shown in 9, it also includes A movable briquetting block positioning frame 19 is movably equipped with an adjustable positioning bracket 20 and a movable locating briquetting block 21 arranged up and down on it, to adapt to the engine location of different sizes and specifications. There are two locking holes on the adjustable positioning bracket 20, corresponding to two positions of extension and contraction respectively, which can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com