Compound technology of biomembrane and granular sludge for treating sulfur-bearing organic wastewater

A technology for granular sludge and organic wastewater, which is applied in waste fuel, anaerobic digestion treatment, biological sludge treatment, etc. It can solve the problems of particle loss, high effluent SS, deterioration of effluent quality, etc., and achieve extended residence time and efficient reduction. , the effect of increasing the holding capacity of the creature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

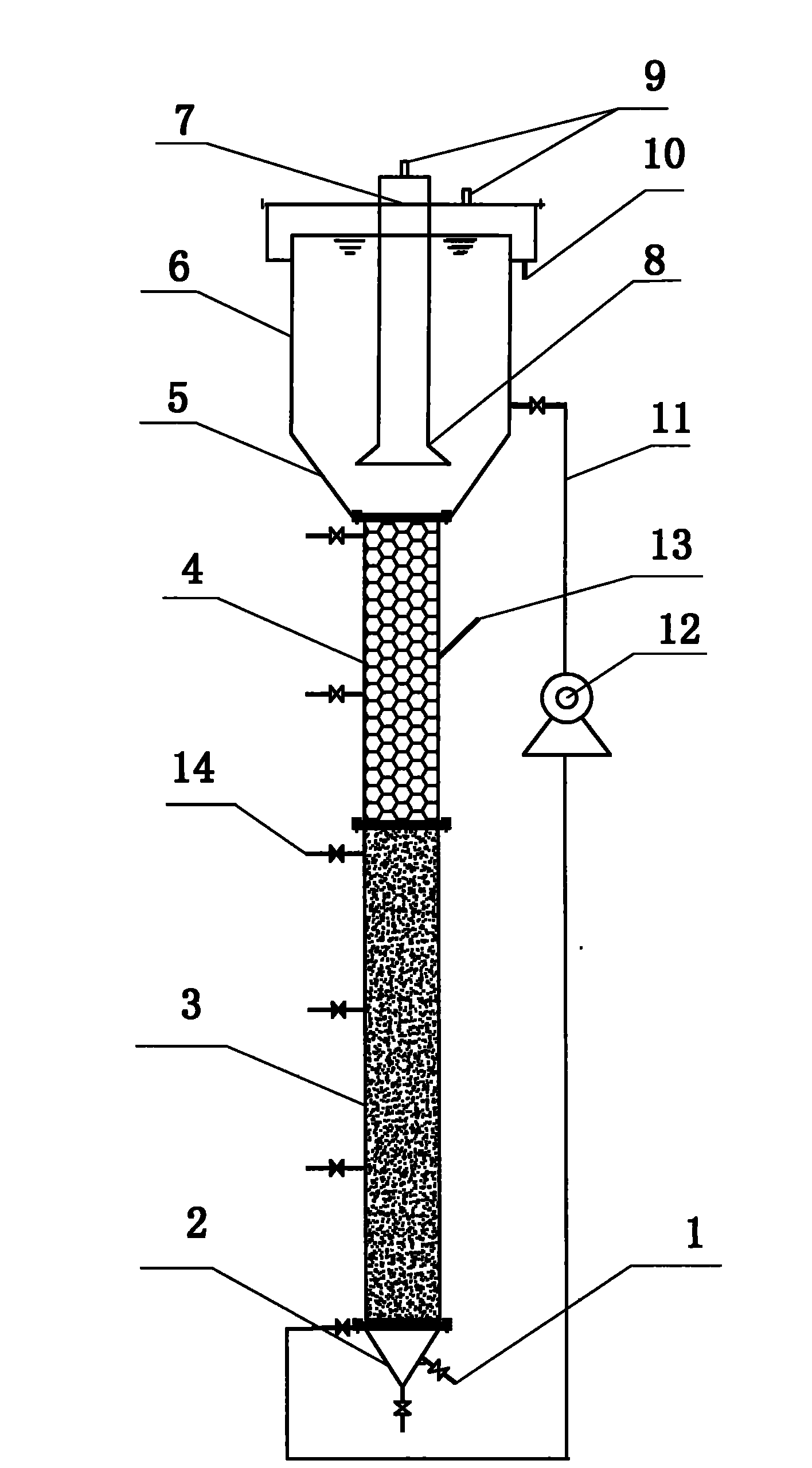

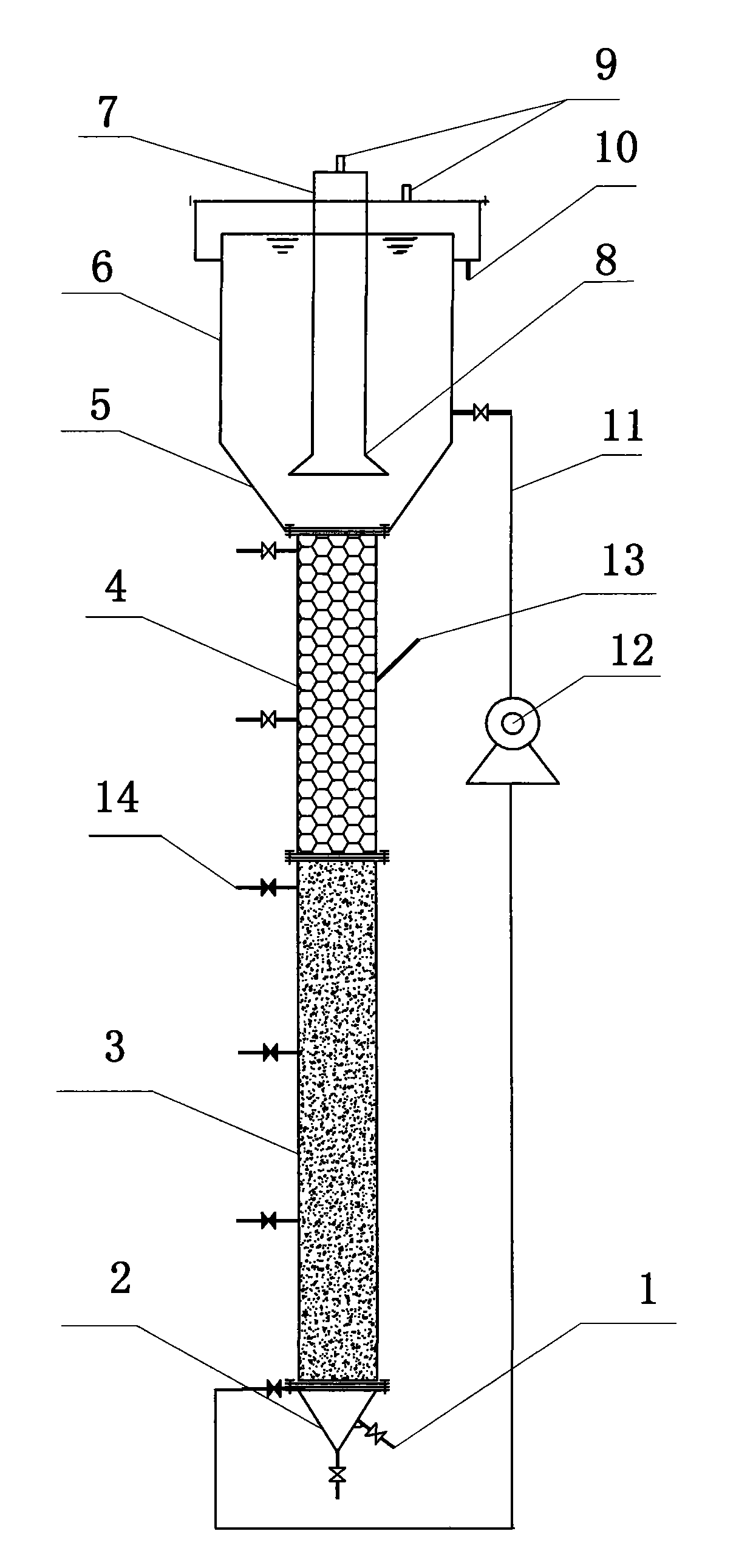

[0011] Specific implementation mode one: as figure 1 As shown, a biofilm and granular sludge composite process for treating sulfur-containing organic wastewater described in this embodiment is realized based on an anaerobic biofilm and granular sludge composite device. The device includes a water inlet pipe 1, Water distribution device 2, sludge bed area 3, packing area 4, transition area 5, settling area 6, gas collection chamber 7, three-phase separator 8, return pump 12 and return pipe 11, the water distribution device 2, sewage The mud bed area 3, the filling area 4, the transition area 5, and the settlement area 6 are arranged in sequence from bottom to top and communicate with each other, and the filling area 4 and the sludge bed area 3 form a reaction area; it is characterized in that the process is realized by the following steps:

[0012] Step 1. Mix the bio-augmented bacteria solution and the filler in the container at a volume ratio of 1:10, add the nutrient solutio...

specific Embodiment approach 2

[0015] Specific embodiment two: The bioaugmented bacterial liquid described in this embodiment is the sulfate-reducing bacteria expansion culture liquid separated and screened from the activated sludge that is rich in sulfate organic wastewater, and the concentration is 10 10 ~10 12 cfu / ml. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: the nutrient solution described in this embodiment is composed of glucose, sodium sulfate, urea and potassium dihydrogen phosphate, wherein the concentration of glucose is 500 mg / L, the concentration of sodium sulfate is 148 mg / L, the concentration of urea is 27 mg / L, phosphoric acid Potassium dihydrogen concentration is 11mg / L; COD, SO 4 2- , N, P concentration ratio is 200:100:5:1. Others are the same as in the first embodiment.

[0017] Specific implementation mode four: as figure 1 As shown, the simulated sulfate-containing organic wastewater is treated with an anaerobic biofilm and granular sludge composite device. The filler used in the filler area is a hanging soft fiber bundle filler, and the fiber bundle filler is fixed on the center rope at a certain distance. Both ends of the central rope are connected with the fixing frame, and the fiber bundle filler is fixed in the composite device of anaerobic biofilm and granular sludge thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com