Method for fixing pile head in filling pile static loading test

A fixing method and static load test technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the waste of manpower and material resources, the steel sleeve cannot be removed or is difficult to remove, and the verticality and elevation of steel sleeve installation are not easy to control and other issues to achieve the effect of improving work efficiency, reducing rework rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

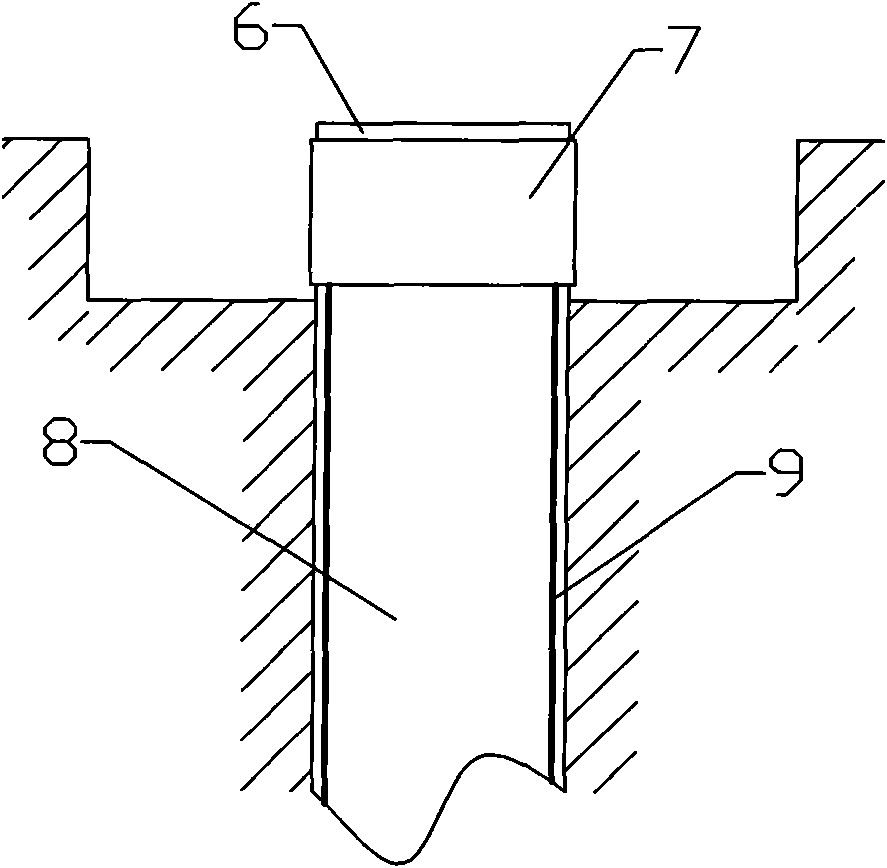

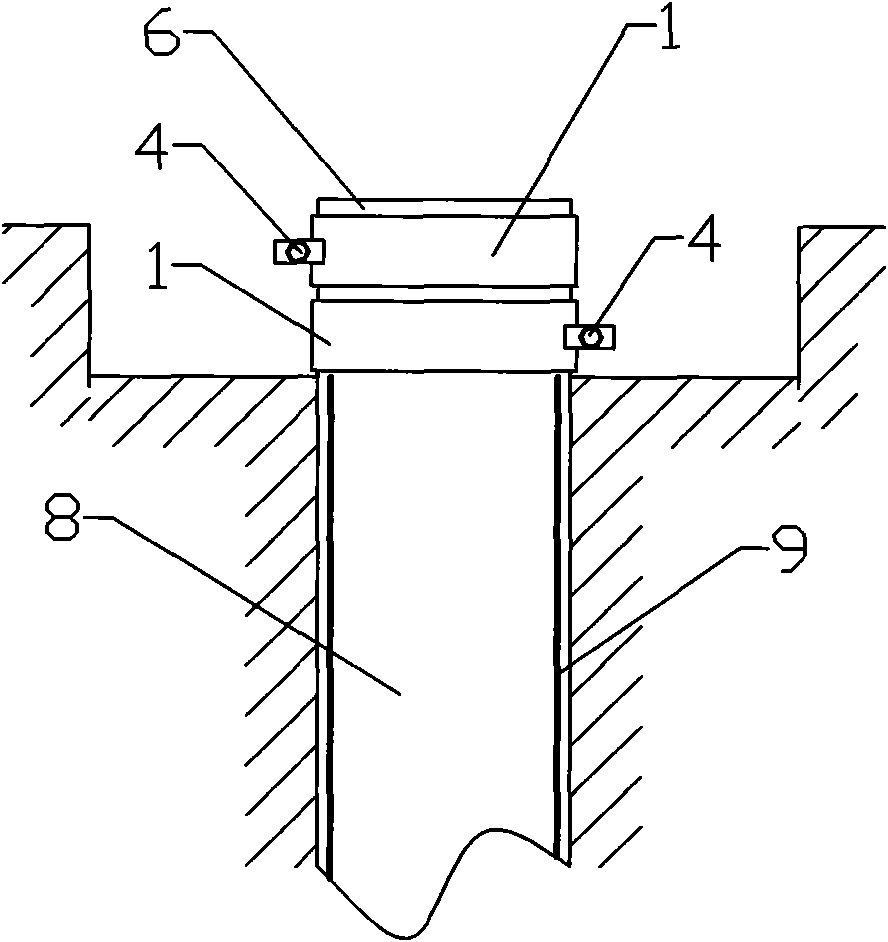

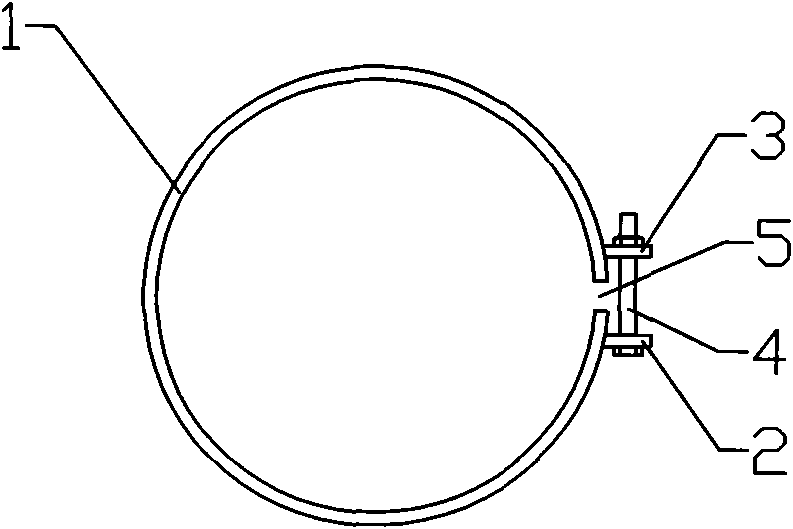

[0016] Example 1, the construction of the cast-in-place pile body 8 and steel cage 9 of a high-rise building filled with superfluid helical drilling is completed, and after the cast-in-place pile is piled, the concrete age of the pile to be inspected reaches 28 days or is reserved for the same condition of curing test. When the block strength reaches the design strength, dig out the cast-in-place pile head 6 on the upper end of the cast-in-place pile body 8, chisel the cast-in-situ pile head 6 to the design elevation, and then fix 2 steel hoops on the cast-in-place pile head 6, 2 The spacing between steel hoop metal sleeves 1 is 15cm, forming as figure 2 According to the structure shown, fill the gap between the steel hoop and the cast-in-situ pile head 6 with a filler, the filler is sieved fine sand, and the sieved fine sand makes the steel hoop fully contact with the cast-in-place pile head 6, and then adjust the tightness The adjusting bolt 4 of the fixing mechanism fasten...

Embodiment 2

[0018] Example 2, the construction of the cast-in-place pile 8 and steel cage 9 poured with superfluid helical drilling in a high-rise building is completed. After the cast-in-place pile is piled, the concrete age of the pile to be inspected reaches 28 days or is reserved for curing under the same conditions. When the block strength reaches the design strength, dig out the cast-in-place pile head 6 on the upper end of the cast-in-place pile body 8, chisel the cast-in-situ pile head 6 to the design elevation, and then fix 2 steel hoops on the cast-in-place pile head 6, 2 The spacing between steel hoop metal sleeves 1 is 15cm, forming as figure 2 In the structure shown, fill the gap between the steel hoop and the cast-in-situ pile head 6 with a filler, the filler is water glass, and the water glass makes the steel hoop fully contact with the cast-in-situ pile head 6, and then adjust the adjustment of the fastening mechanism Bolt 4 fastens the steel hoop on the cast-in-situ pile...

Embodiment 3

[0020] Example 3, the construction of the cast-in-place pile 8 and the reinforcement cage 9 of a high-rise building filled with superfluid helical drilling is completed. After the cast-in-place pile is piled, the age of the concrete of the pile to be inspected reaches 28 days or is reserved for curing under the same conditions. When the block strength reaches the design strength, dig out the cast-in-place pile head 6 on the upper end of the cast-in-place pile body 8, chisel the cast-in-situ pile head 6 to the design elevation, and then fix 2 steel hoops on the cast-in-place pile head 6, 2 The spacing between steel hoop metal sleeves 1 is 15cm, forming as figure 2 In the structure shown, fill the gap between the steel hoop and the cast-in-situ pile head 6 with a filler, the filler is mortar, and the mortar makes the steel hoop and the cast-in-place pile head 6 fully contact, and then adjust the adjusting bolt 4 of the fastening mechanism Fasten the steel hoop on the pile head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com