Rolling bearing and sealing component for rolling bearing

A technology for rolling bearings and sealing components, applied to bearing elements, rigid supports of bearing components, ball bearings, etc., can solve the problems of waterproof function, dustproof function reduction, complex appearance of products, and inability to use, etc., to improve the antirust effect , to achieve anti-rust effect, to prevent the intrusion of water and soil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

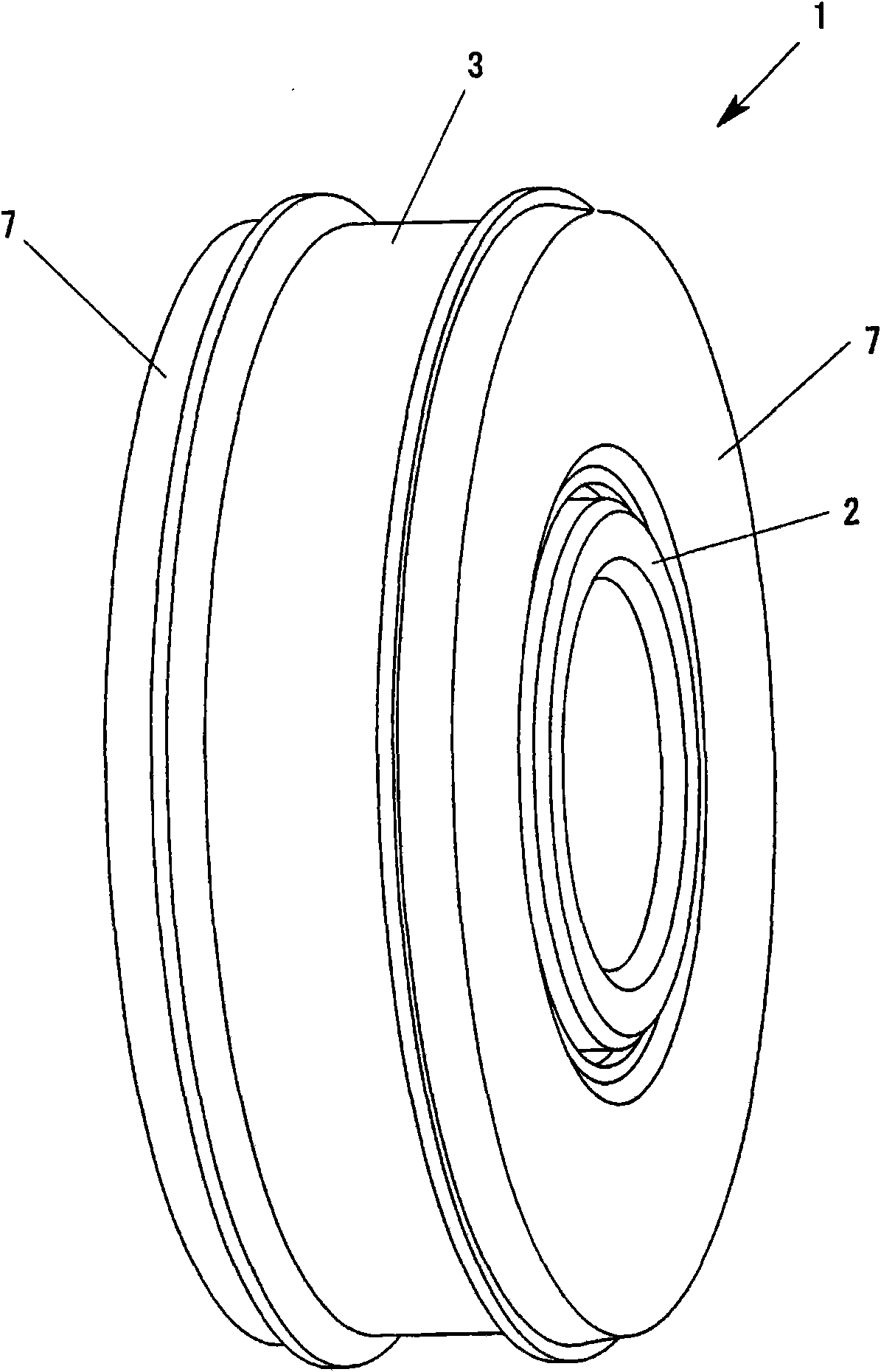

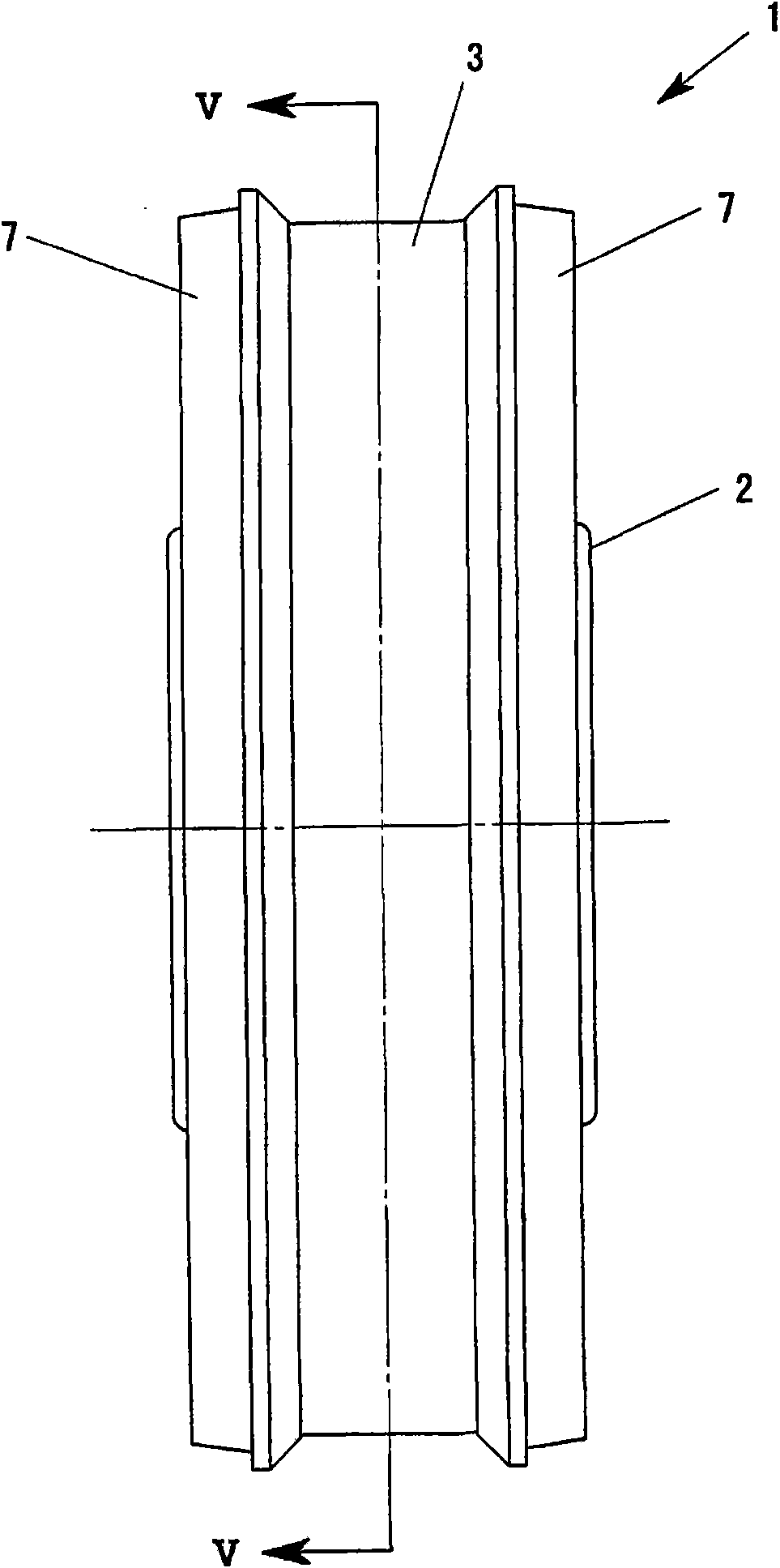

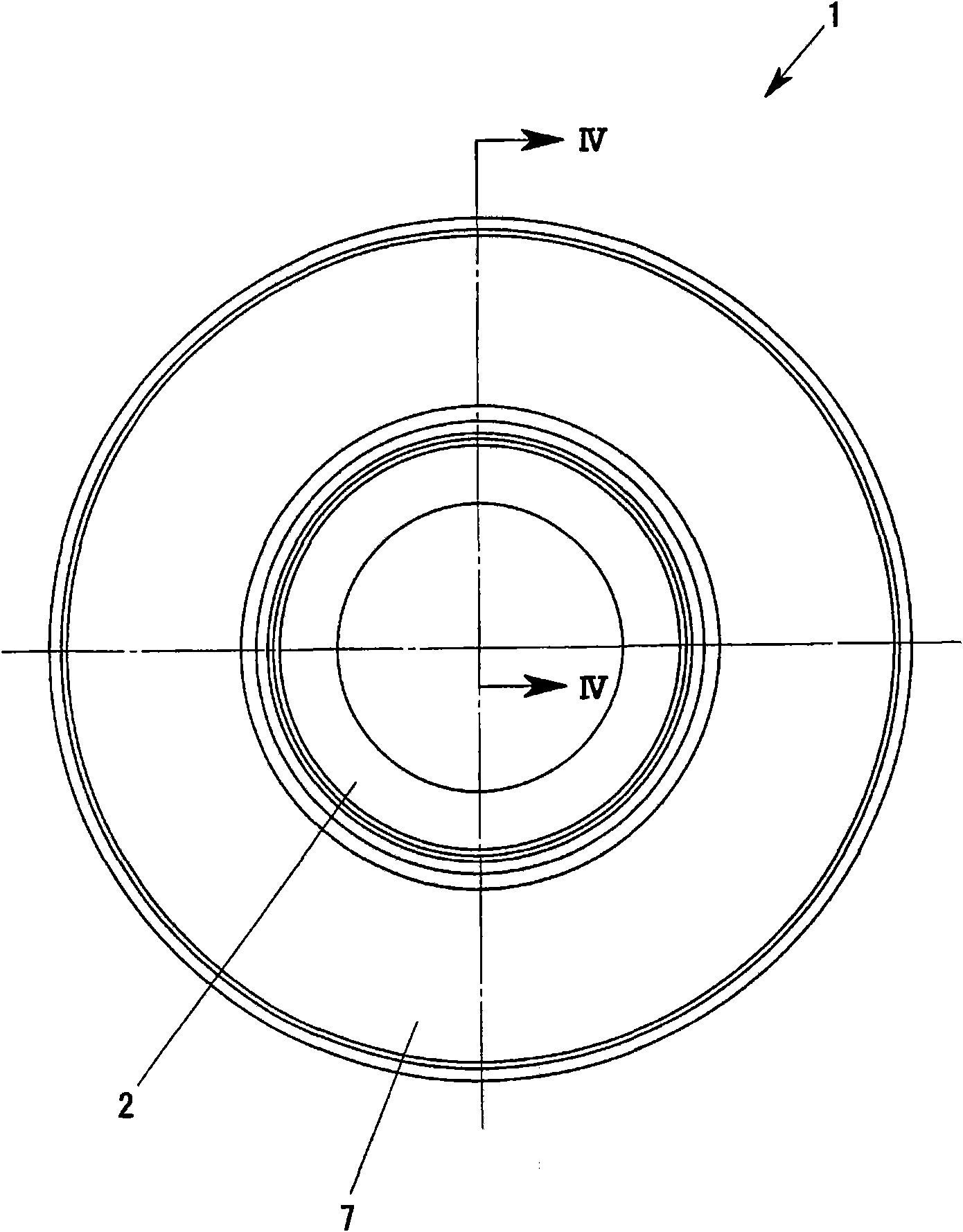

[0060] figure 1 It is a perspective view showing an appearance structure of a sealed rolling bearing 1 according to an embodiment of the present invention. figure 2 is a front view of the rolling bearing 1. image 3 It is the right side view of the rolling bearing 1. Figure 4 yes image 3 Sectional view of line IV-IV in. Figure 5 yes figure 2 The V-V line profile in. Image 6 It shows the state where the rolling bearing 1 is housed in the outer ring housing member 8, which is equivalent to Figure 4 sectional view. Figure 7 It shows the state that the rolling bearing 1 is housed in another outer ring housing member 9, which is equivalent to Figure 4 sectional view.

[0061] Such as Figure 4 As shown in detail, the rolling bearing 1 includes an inner ring 2, an outer ring 3, and a plurality of steel balls 5 arranged in an annular space 4 between the inner ring 2 and the outer ring 3. A cage 6 that rotatably supports the steel balls 5 is maintained at a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com