Magnetic grab bucket

A grab and ferromagnetic technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problems of not being able to automatically identify whether the workpiece has been received or the workpiece has been lost, and achieve the effect of simple structure and no inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

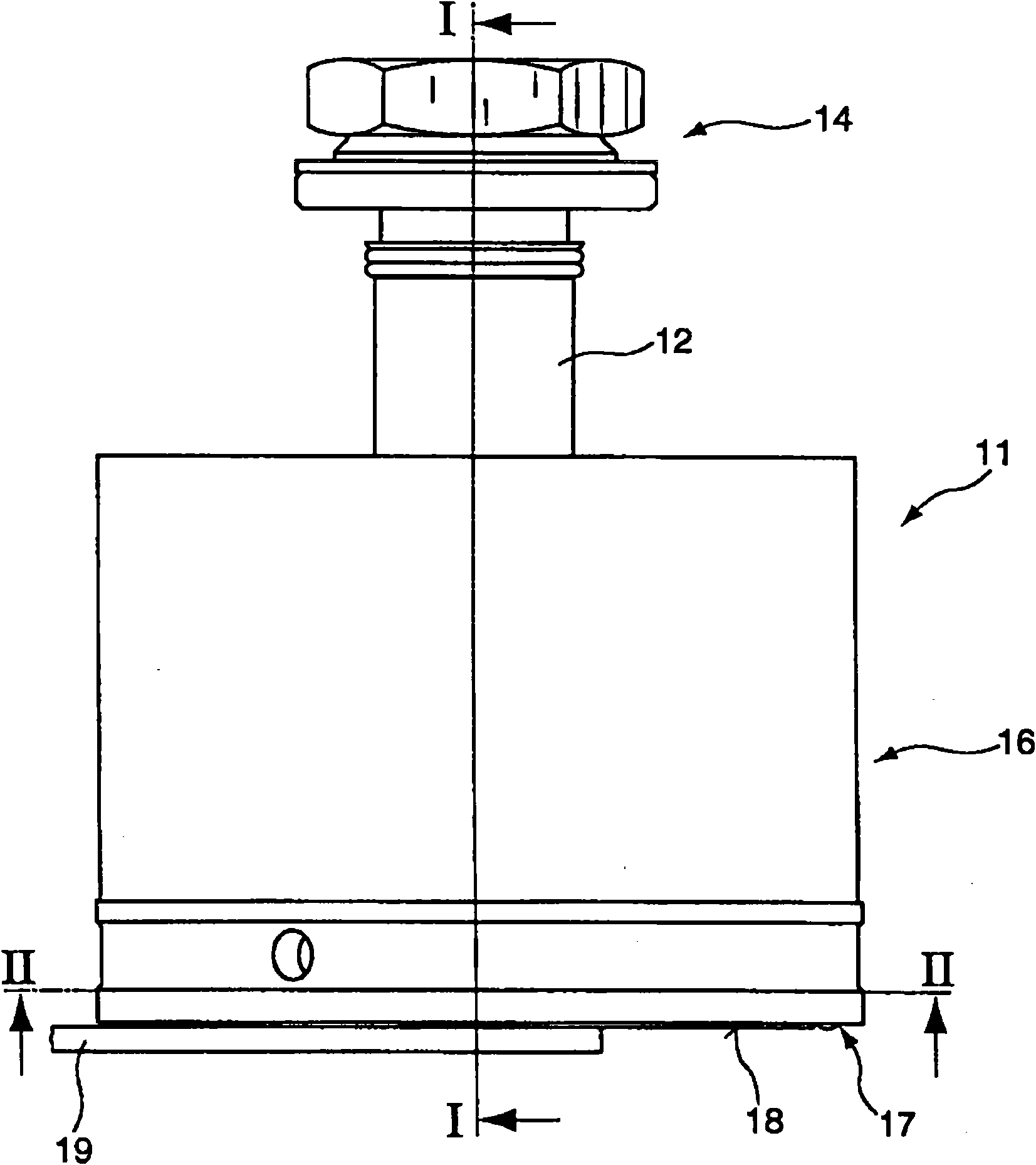

[0030] figure 1 A schematic side view of a magnetic grab 11 is shown having a neck 12 with fastening means 14 for fastening the magnetic grab to a robot arm or handling device. On the opposite side, a housing base 17 is provided on the cup-shaped housing 16 , which is screwed onto the housing 16 , for example. The housing base 17 has an end face 18 which is abutted by a gripped workpiece 19 , represented for example as a ferromagnetic plate.

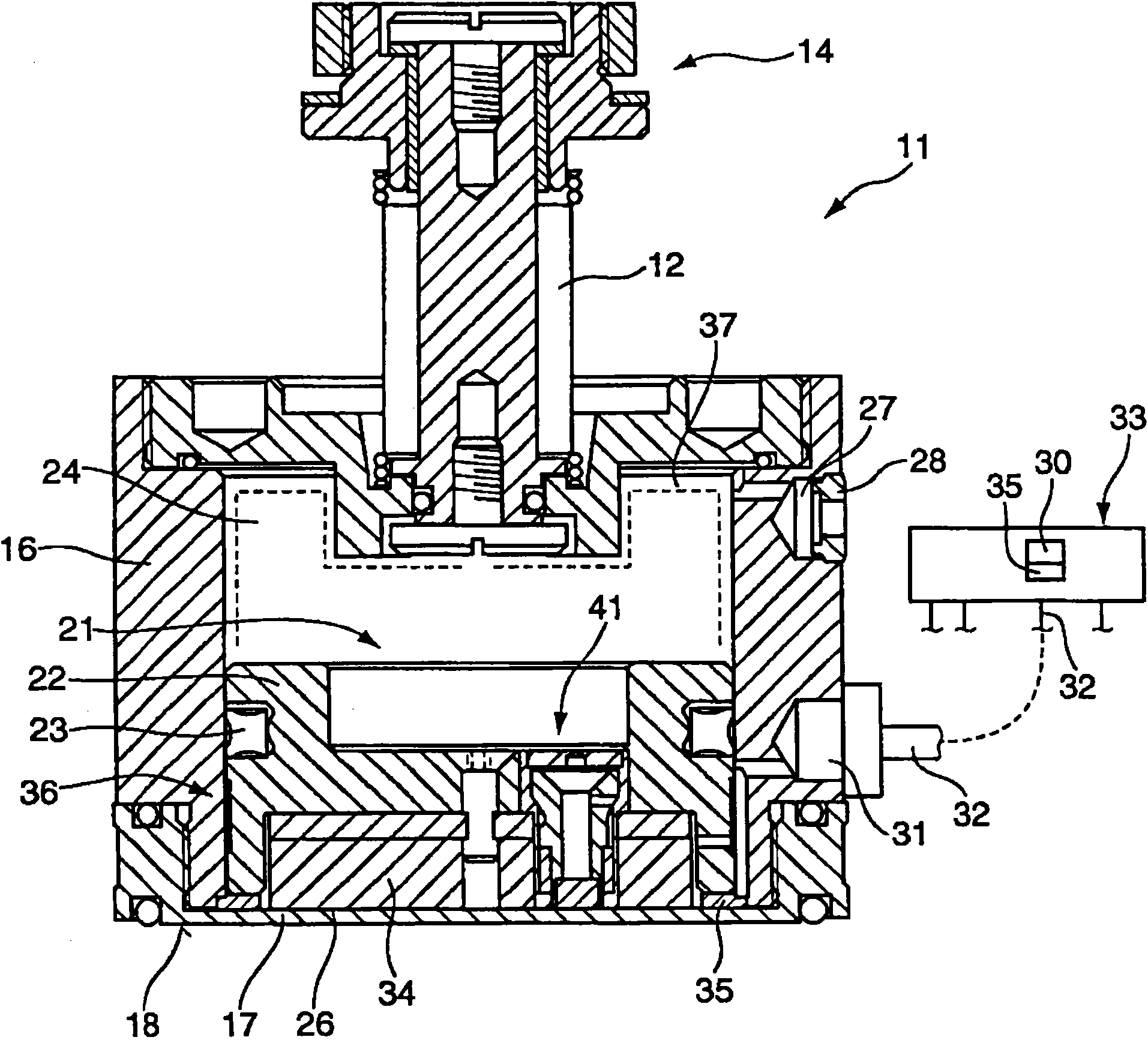

[0031] exist figure 2 is shown along the figure 1 Line I-I among is the sectional view that magnetic grab bucket 11 is done. In the housing 16 a magnetic piston 21 is guided so as to be movable up and down. The magnetic piston 21 comprises a guide ring 22 in which is arranged a seal 23 which separates an action chamber 24 present above the magnetic piston 21 from a piston chamber 26 present between the magnetic piston 21 and the housing base 17 . The volumes of these two chambers 24 , 26 are defined to be inversely proportional to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com