Four-way exhaust gas valve

A technology of four-way exhaust valve and exhaust flow direction, which is applied in the direction of multi-way valve, exhaust treatment, exhaust device, etc., to achieve the effect of easy actuation and avoiding excessive deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

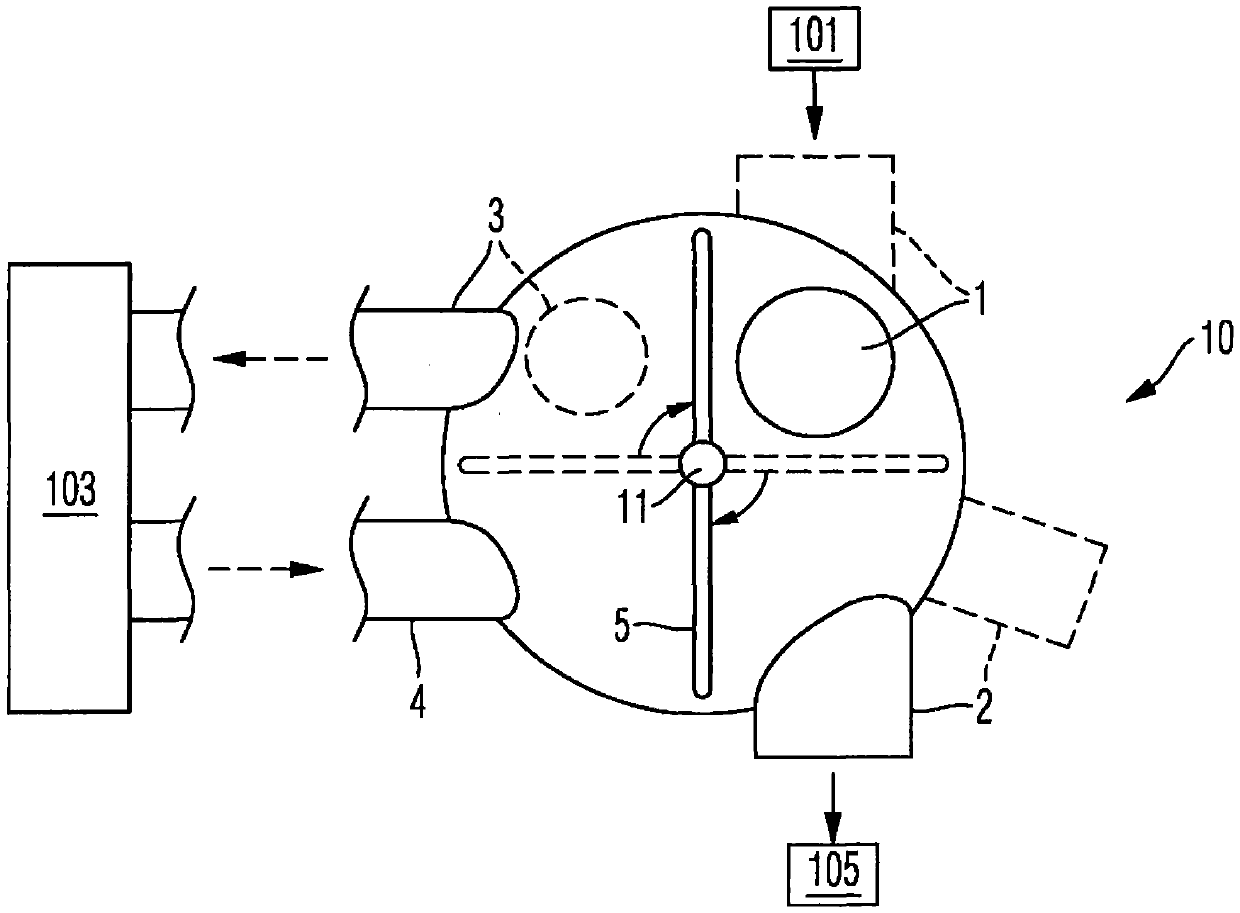

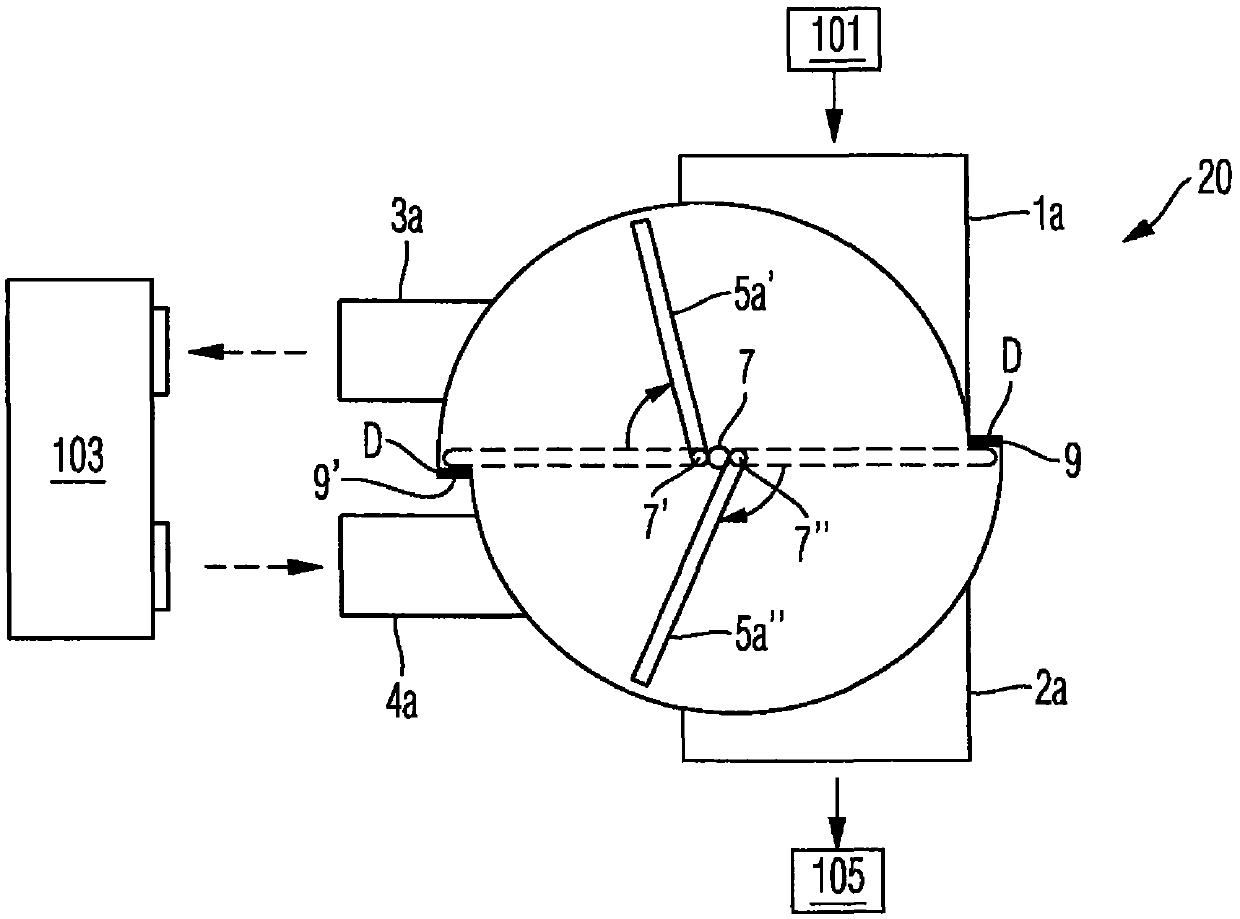

[0051] In the exemplary embodiments described below, components with the same function and structure are denoted by the same reference numerals as much as possible. Therefore, in order to understand the features of the individual components of a particular embodiment, reference should be made to the descriptions of other embodiments and the description of the Summary section.

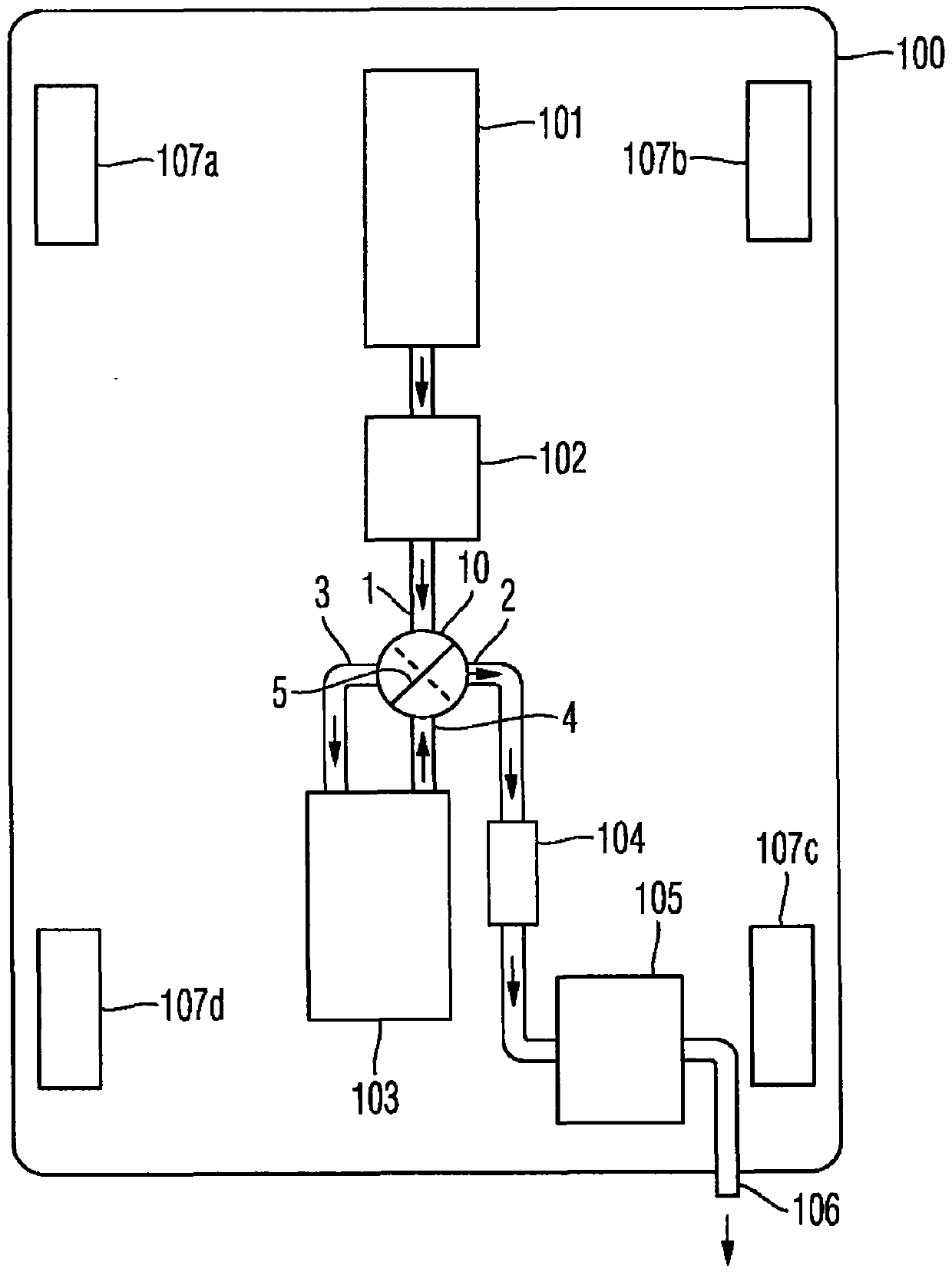

[0052] figure 1 A bottom view of the bottom of a vehicle is schematically shown.

[0053] Near the wheels 107a, 107b, 107c, 107d, at the bottom of the vehicle 100, the bottom of the internal combustion engine 101, the exhaust turbocharger 102, the four-way exhaust valve 10 according to the invention, the latent heat store 103, the catalytic converter 104 are visible and silencer 105.

[0054] Internal combustion engine 101 is arranged between front wheels 107a and 107b, and is coupled to exhaust turbocharger 102 such that exhaust gas discharged from internal combustion engine 101 flows through exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com