Vehicle-mounted scr catalyst on-site regeneration equipment

A SCR catalyst and vehicle-mounted technology, which is applied in the field of flue gas purification, can solve the problems of complex and cumbersome operation process and high catalyst cost, and achieve the effects of simple operation, saving manpower and material resources, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

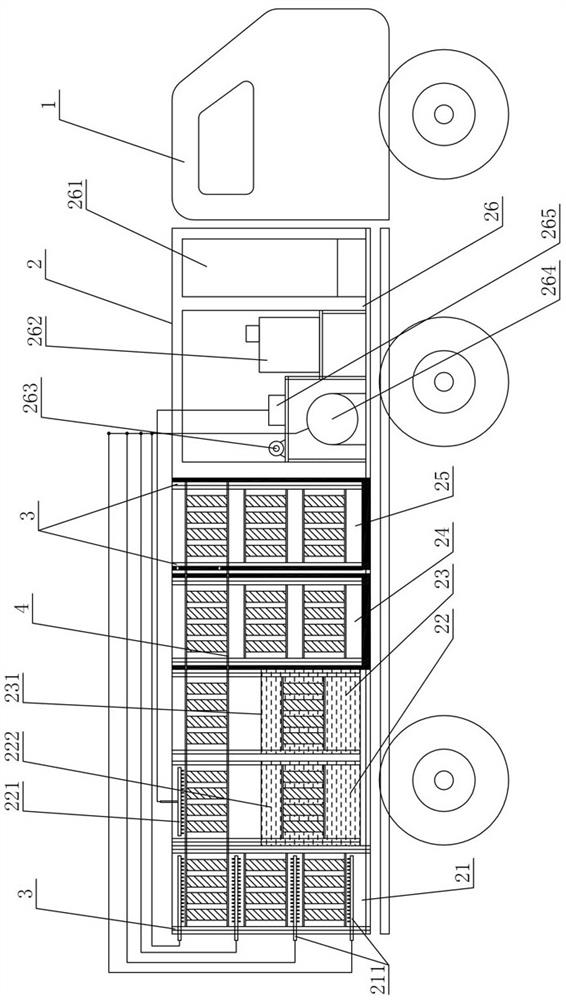

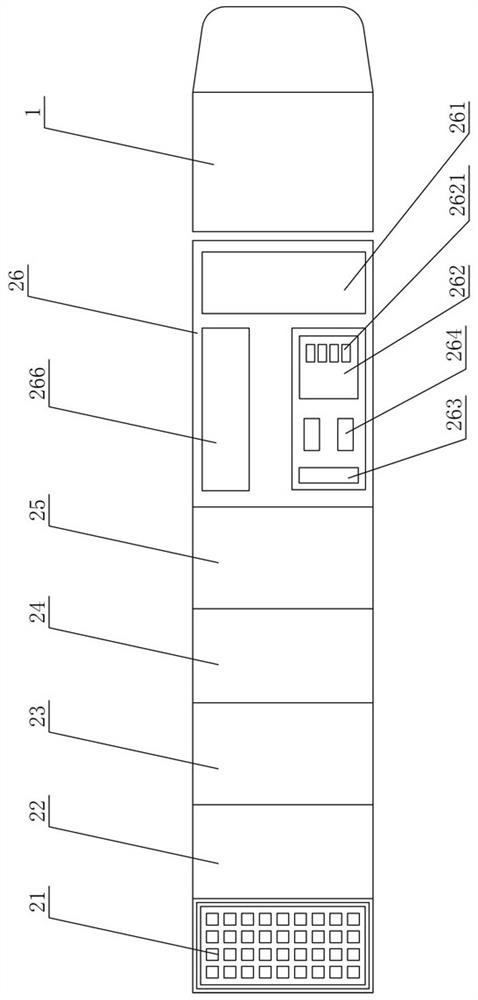

[0022] Such as figure 1 and figure 2 As shown, an embodiment of the vehicle-mounted SCR catalyst on-site regeneration equipment of the present invention includes a carrier vehicle 1, a carriage 2 is provided on the carriage 1, and a spray cleaning area 21 and a spray cleaning area 22 are sequentially arranged in the carriage 2 , activation solution impregnation zone 23, drying zone 24 and roasting zone 25, each zone is provided with a lifting track 3 for transporting the SCR catalyst up and down, and the top of each zone is also provided with a shared translation track 4 for transporting the translation of the SCR catalyst, and the carriage 2 There is also a control area 26 for controlling the operation of the spray cleaning area 21, the spray cleaning area 22, the lifting track 3 and the translation track 4. When in use, the inval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com