Chip chuck

A chip and chuck technology, applied in the field of chip chucks, can solve problems such as low efficiency, chip breakdown, affecting chip yield, etc., and achieve the effect of avoiding electrostatic breakdown and meeting the requirements of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

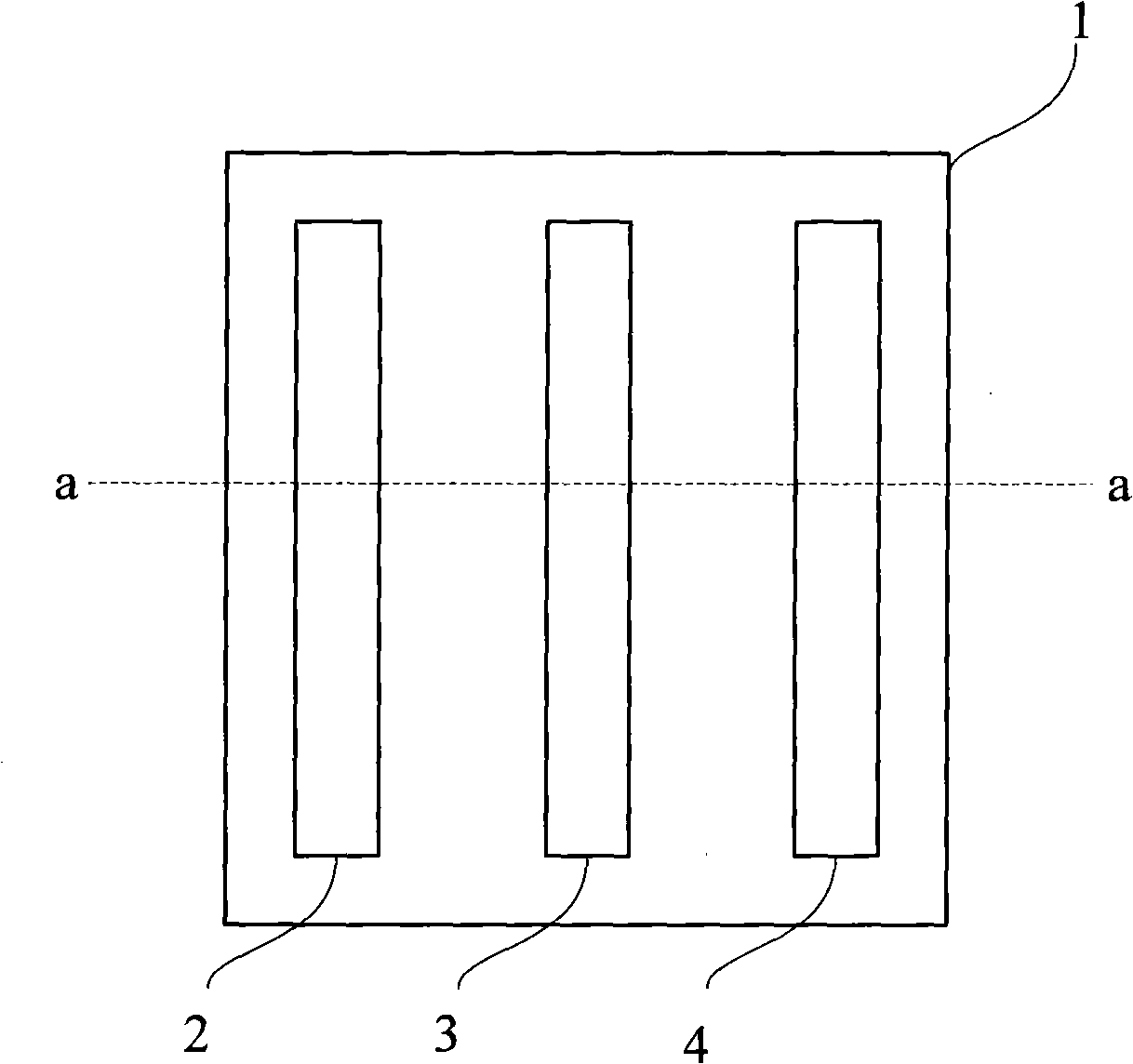

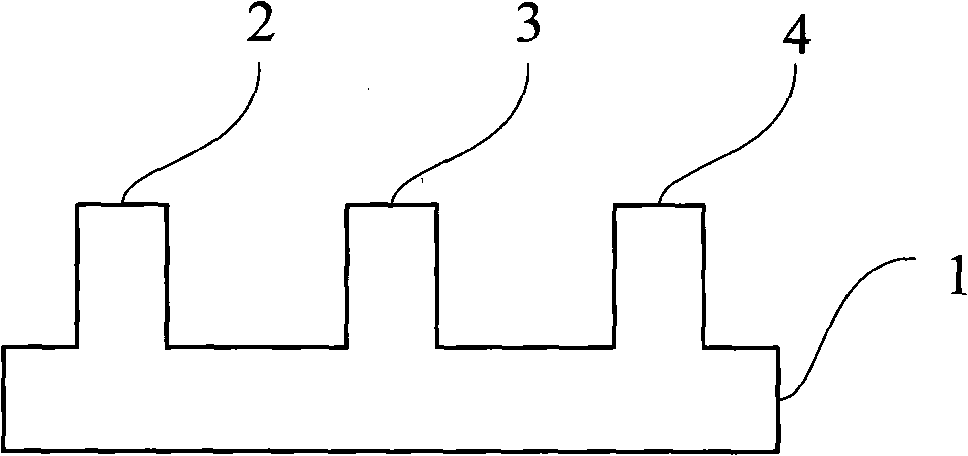

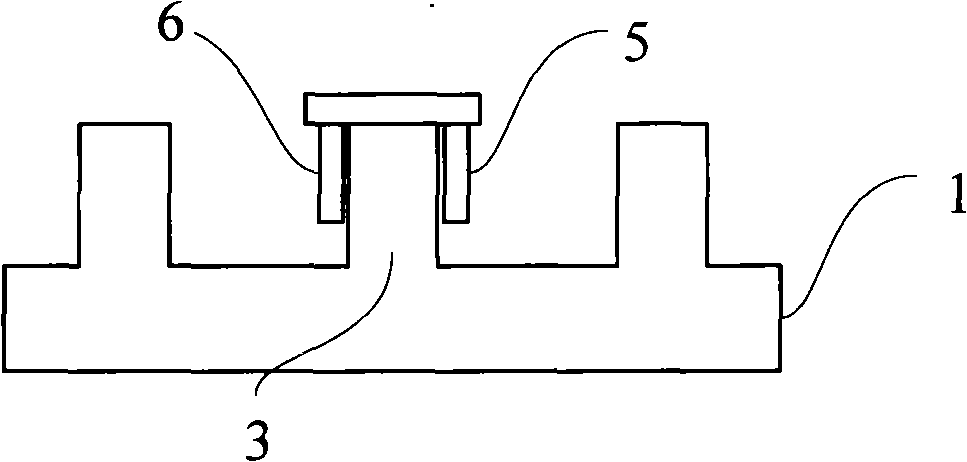

[0016] The specific implementation of the chip chuck provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] attached Figure 4 Shown is a schematic cross-sectional view of the chuck structure of the first specific embodiment of the chip chuck according to the present invention. It includes a base 101, a chip holder 102 on the surface of the base 101, and a target chip placed thereon. According to actual needs, more brackets can also be designed on the surface of the base 101 . The top portion 120 of the chip carrier 102 is attached Figure 4 For the portion above the middle dotted line, the interface of the top portion 120 has a narrow top and a wide bottom.

[0018] When the target chip is not placed on the chip chuck, the two rows of pins 111 and 112 of the chip are parallel to each other, and the distance between the roots of the two rows of pins 111 and 112 is the distance between the two rows of pins....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com