Comprehensive negative sequence and harmonic compensating system of electrified high-speed railway

A comprehensive compensation, high-speed railway technology, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problems of high voltage and current level requirements, complex structure, high cost, etc., to improve the harmonic suppression effect, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

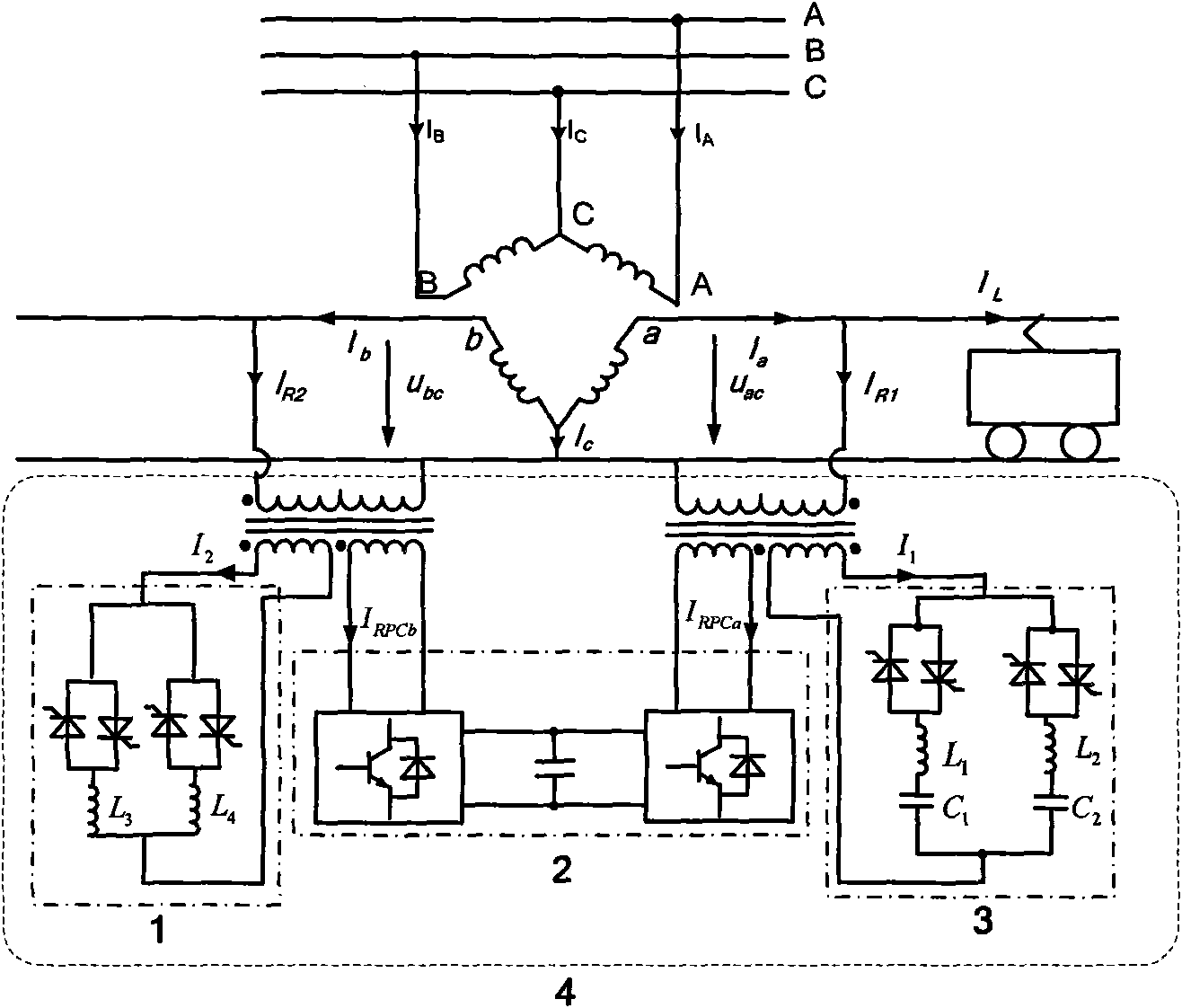

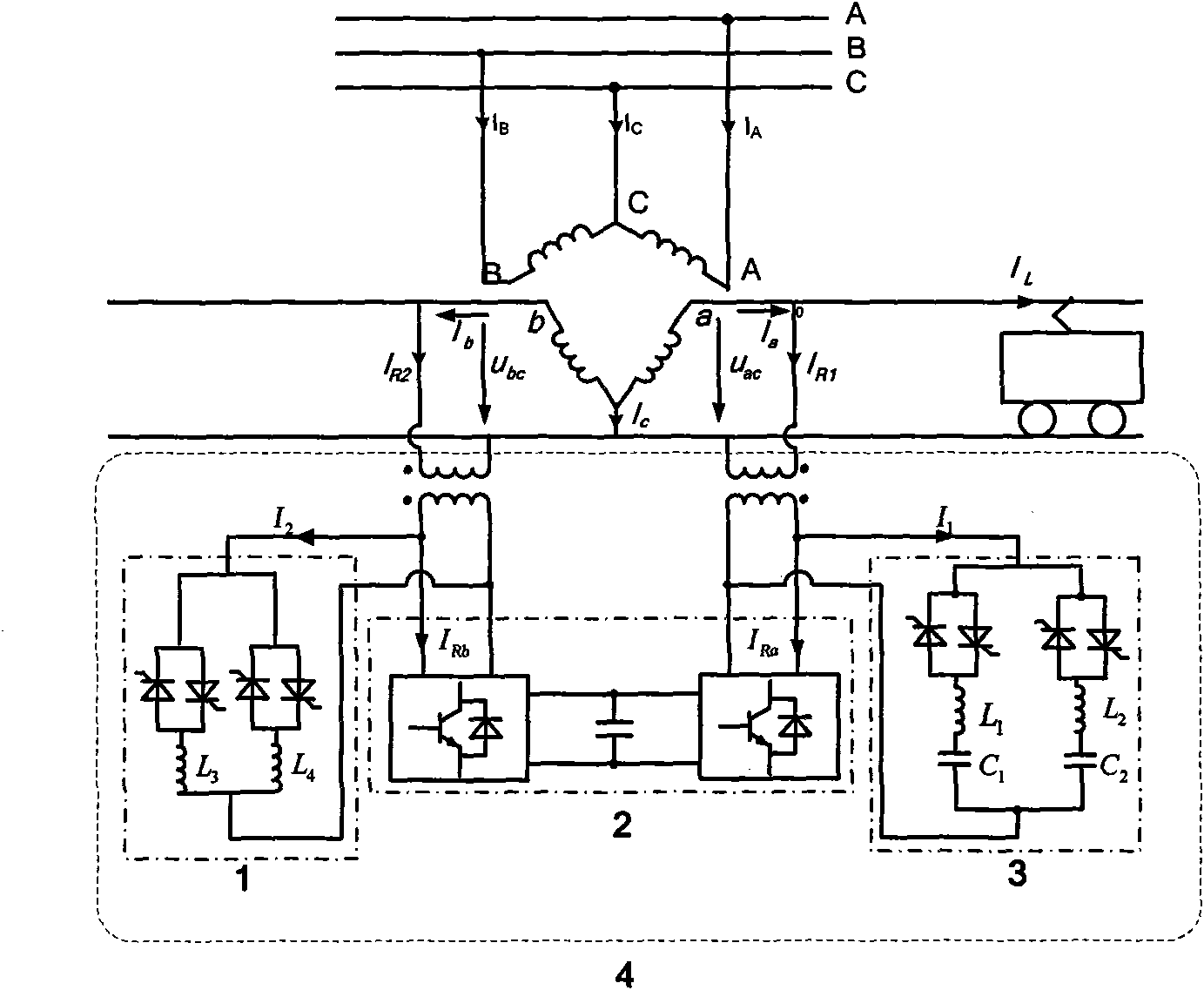

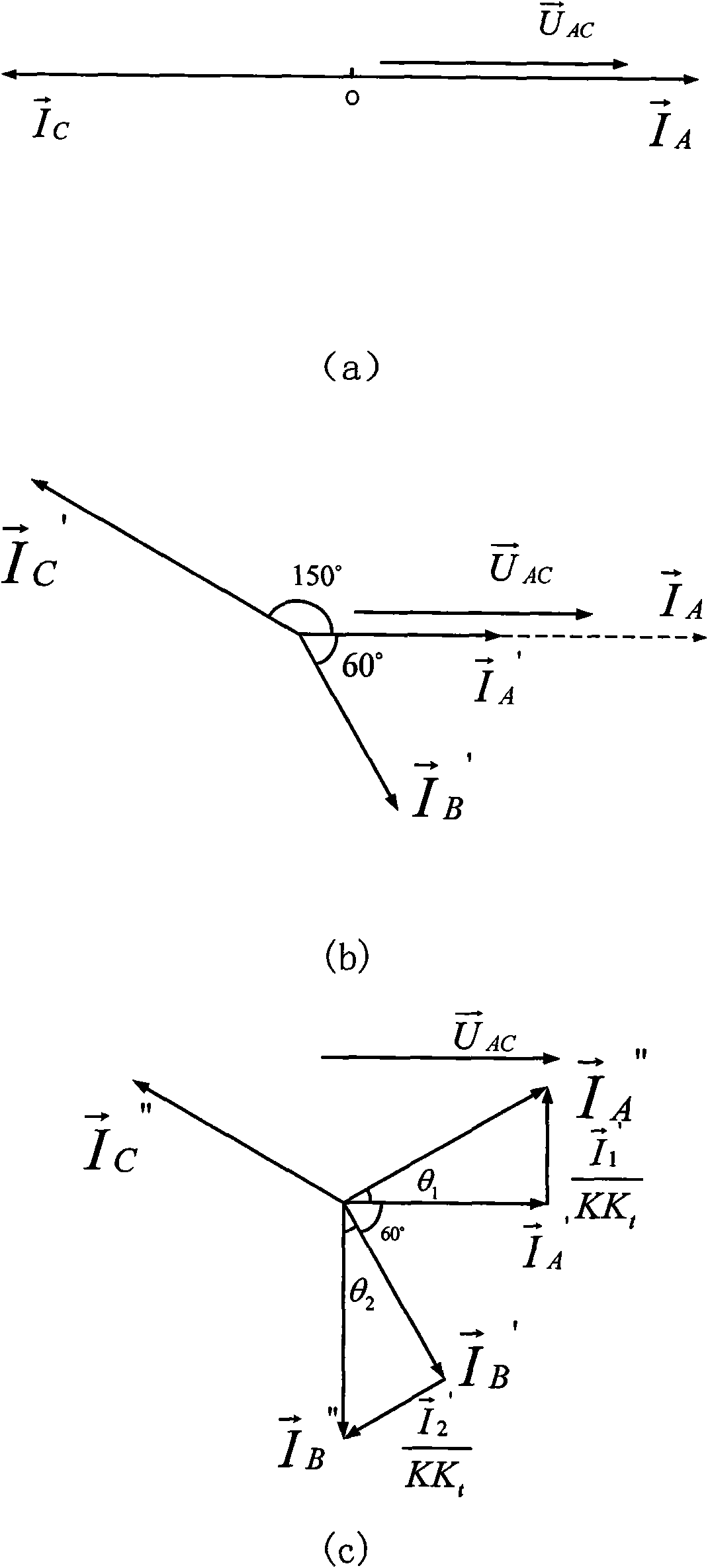

[0015] see figure 1 , figure 1 It is a structural diagram of Embodiment 1 of the present invention. The present invention 4 is composed of a back-to-back railway power conditioner 2 (RPC), two groups of thyristor-controlled high-pass filters 3 (TCHF) with different parameters and thyristor-controlled reactors 1 (TCR). The RPC is installed between the two power supply arms on the secondary side of the three-phase V / V junction traction transformer through two single-phase three-winding step-down transformers. The thyristor-controlled high-pass filter is installed on the two power supply arms connected to the voltage phase leading Under the single-phase three-winding step-down transformer, the thyristor-controlled reactor (L 3 , L 4 ) is installed under two single-phase three-winding step-down transformers connected to the other power supply arm whose voltage phase lags. The RPC contains two converters connected through a shared DC capacitor, and the two converters are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com