Automotive body robot flexible welding system for mixed line production of multiple vehicle types

A technology of automobile body and welding system, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of incomplete application, and achieve the effect of effective function, improved flexibility, and fast and accurate positioning movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

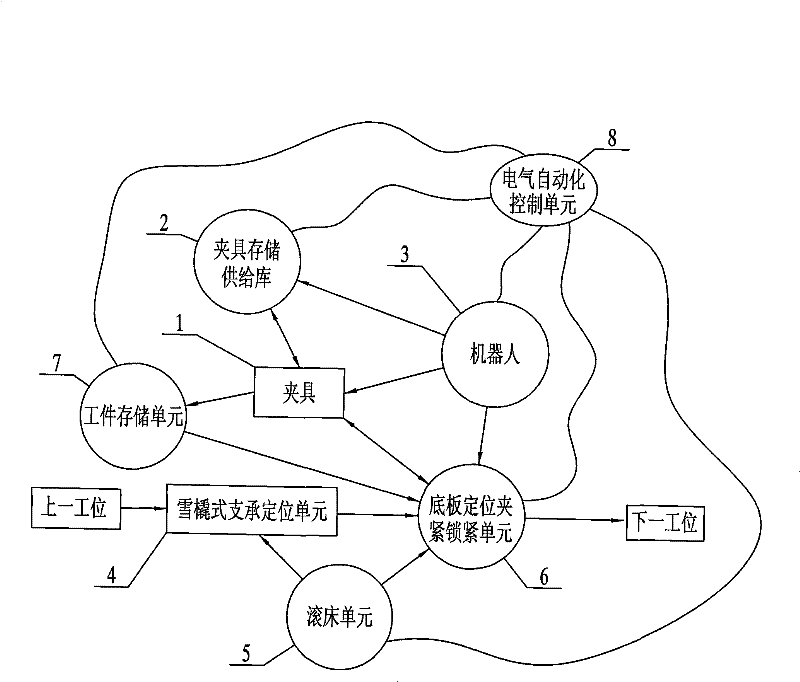

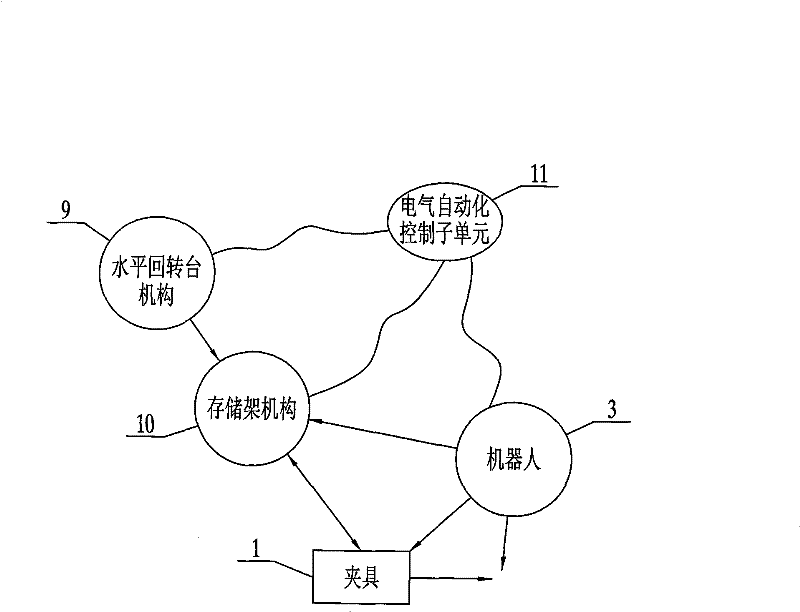

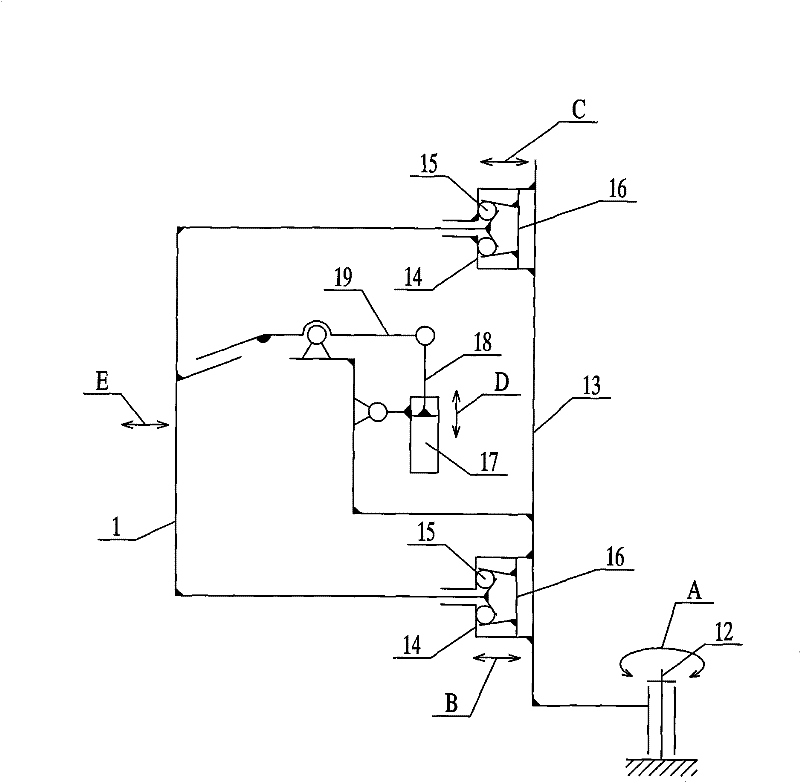

[0023] Refer to the attached figure 1 , The invention discloses a multi-vehicle mixed-line production automobile body robot flexible welding system. This system includes a fixture storage and supply library 2 composed of multiple horizontal rotary fixture storage and supply units for storing multiple fixtures 1; it is installed on a moving slide table for grabbing the fixture 1 to realize automatic quick change between the workpiece and the fixture 1 In place, and a robot 3 for grabbing the robot welding torch to perform welding operations; a sled support and positioning unit 4 for supporting and positioning the workpiece and for transferring the workpiece; a sled support and positioning unit 4 for positioning and clamping and making it move along the production line The rolling bed unit 5 is used for positioning and locking the robot 3 to release the clamp 1 to the clamp working position and is used for positioning and clamping the base plate positioning clamping and locking ...

Embodiment approach

[0026] As a preferred embodiment of the present invention, the specific scheme of the present invention is as follows:

[0027] See figure 1 , composition of the present invention:

[0028] 1, including a fixture storage supply library 2;

[0029] 2, including a robot 3;

[0030] 3. It includes a plurality of sled support positioning units 4;

[0031] 4, including a rolling bed unit 5;

[0032] 5, including a bottom plate positioning clamping and locking unit 6;

[0033] 6, including a workpiece storage unit 7;

[0034] 7, including a set of electrical automation control unit 8.

[0035] A brief description of each of the above components is as follows:

[0036] The jig storage and supply warehouse 2 is a warehouse for storing all the vehicle type jigs 1 in this area of the station, which is organically composed of a plurality of horizontal rotary jig storage and supply units. The warehouse is equipped with 2 horizontal rotary fixture storage supply units. The fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com