Concrete mixer

A concrete mixer and concrete technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of increasing component cross-sections, waste, etc., and achieve the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

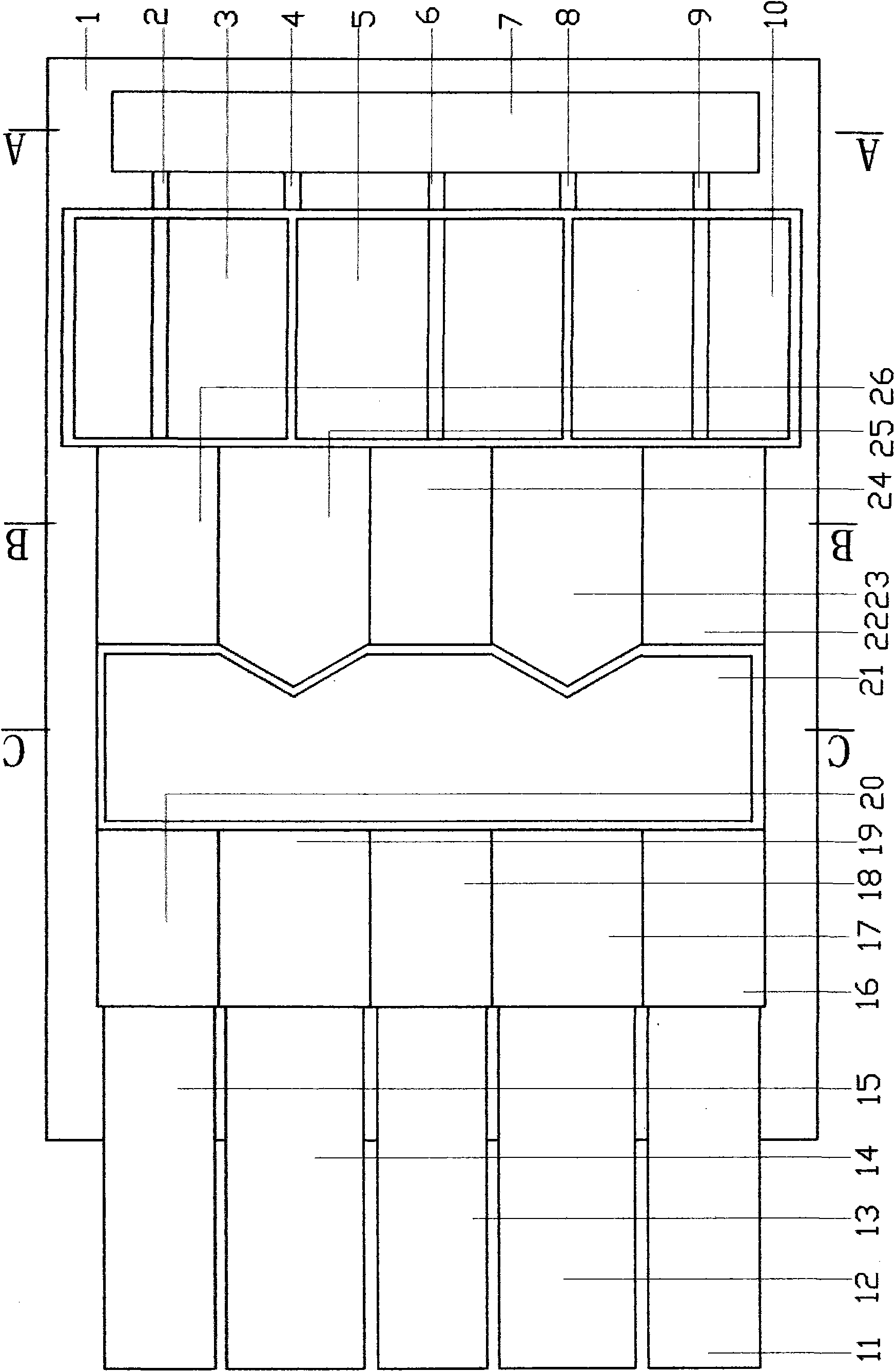

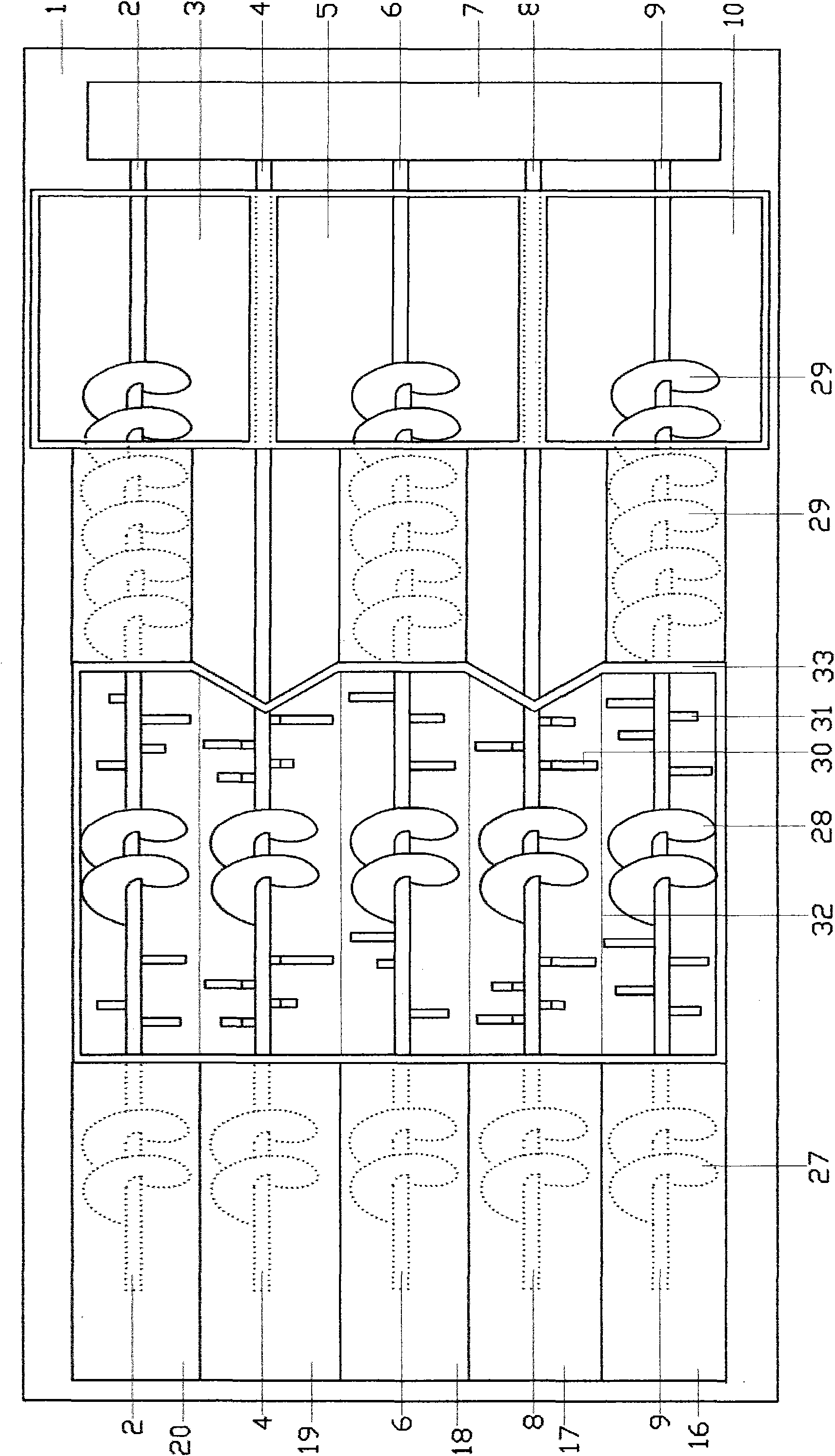

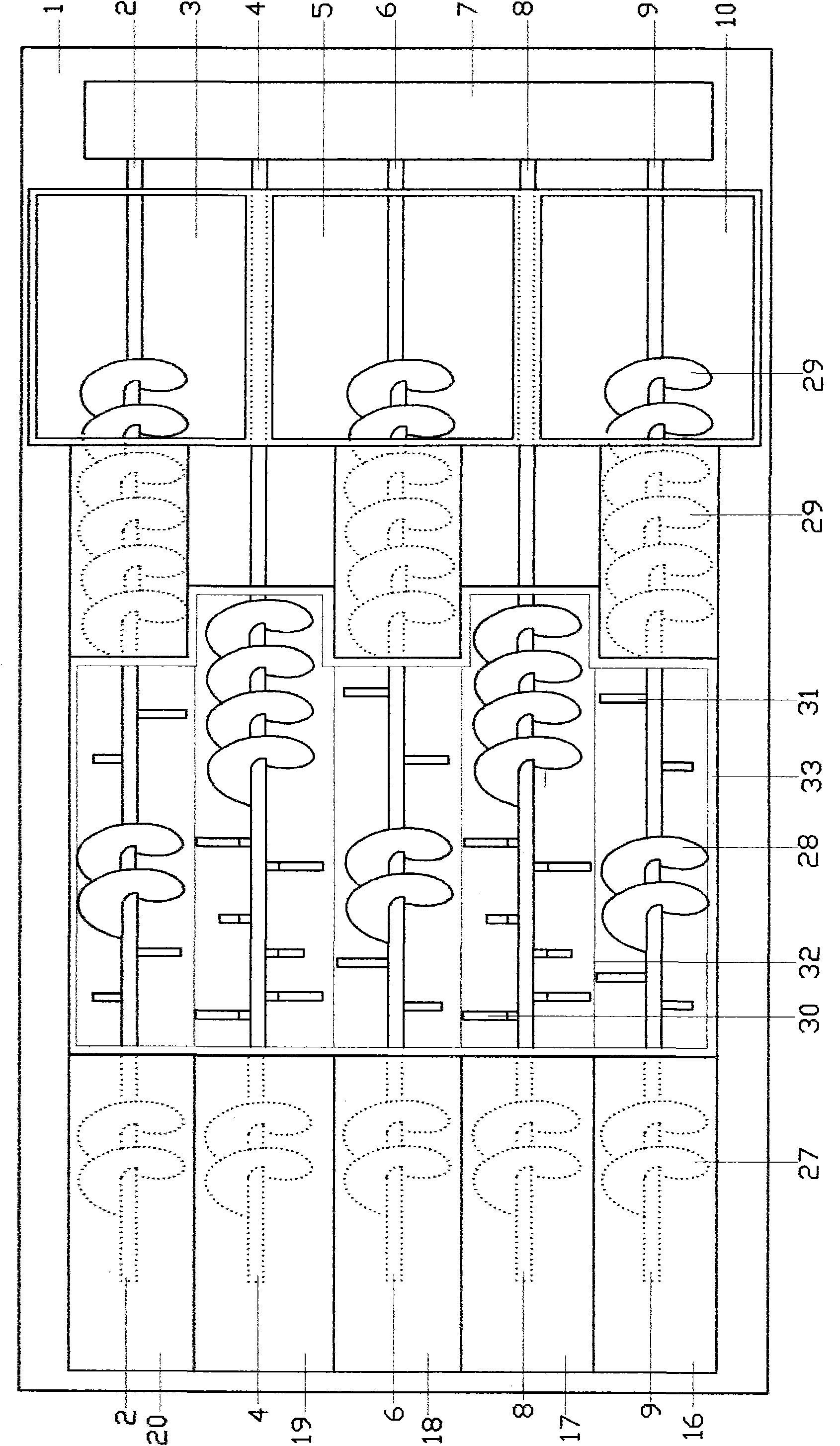

[0051] Taking the structure shown in Figure 2 as an example, the specific implementation method will be described.

[0052] 1. Based on the material requirements of the required new concrete, the unit demand of new concrete and other factors, and comprehensively consider, design the diameter of the feeding cylinder, the capacity of the hopper, the rotational speed of the cutter shaft, the specification and spacing of the propulsion reamer blades;

[0053] 2. Determine the specifications of the discrete reamer according to the flow and velocity of the raw materials in the feed barrel;

[0054] 3. Determine the number of discrete reamers and the specifications of the mixing drum according to the material requirements of the new concrete;

[0055] 4. Determine the specification and quantity of the gathering reamer and the specification of the mixing drum according to the discrete ability of the discrete reamer;

[0056] 5. Determine the specification and quantity of the propulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com