Doctor blade system

A squeegee and ink technology, used in printing, printing machines, general parts of printing machinery, etc., can solve problems such as frequent maintenance, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

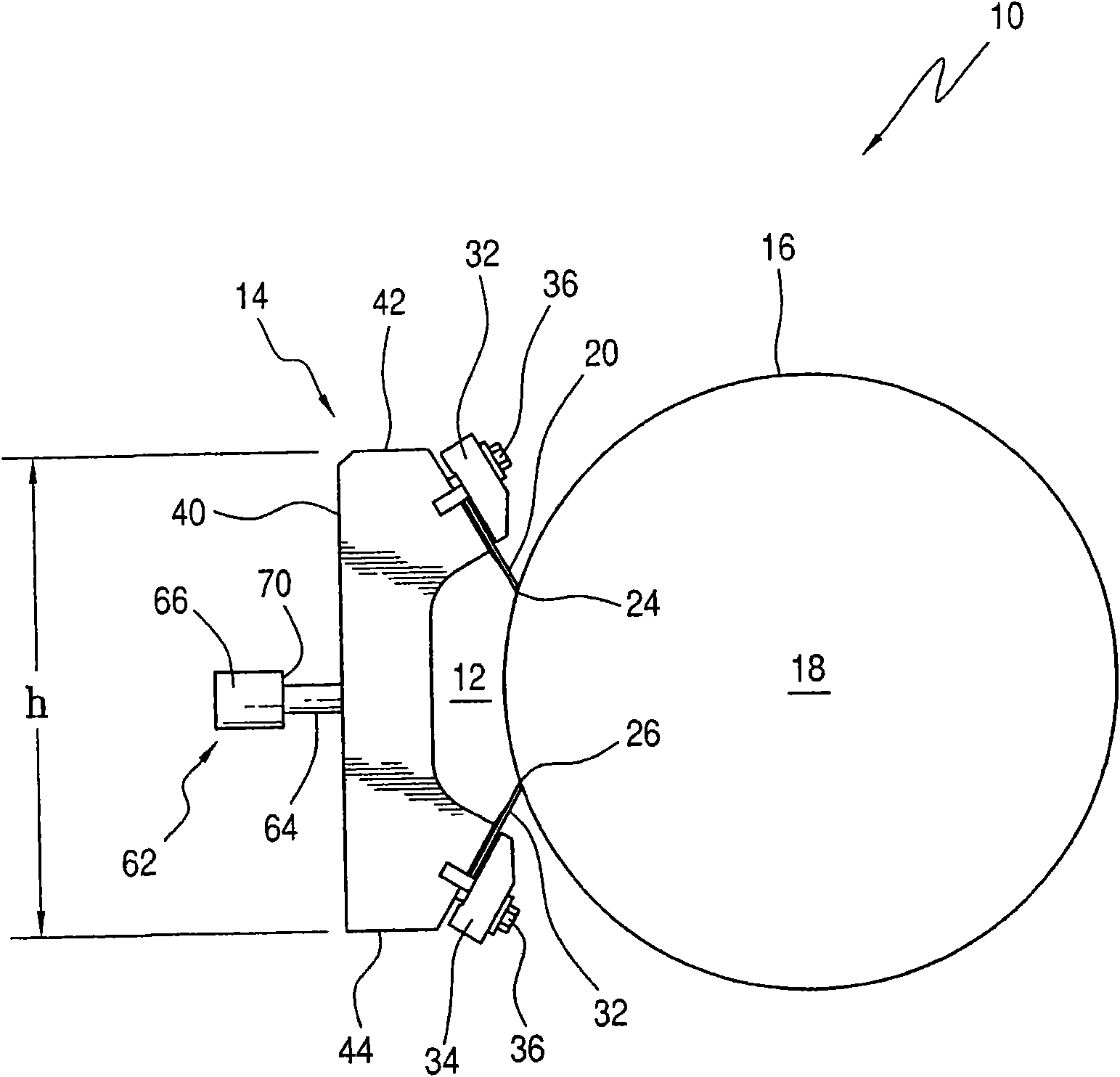

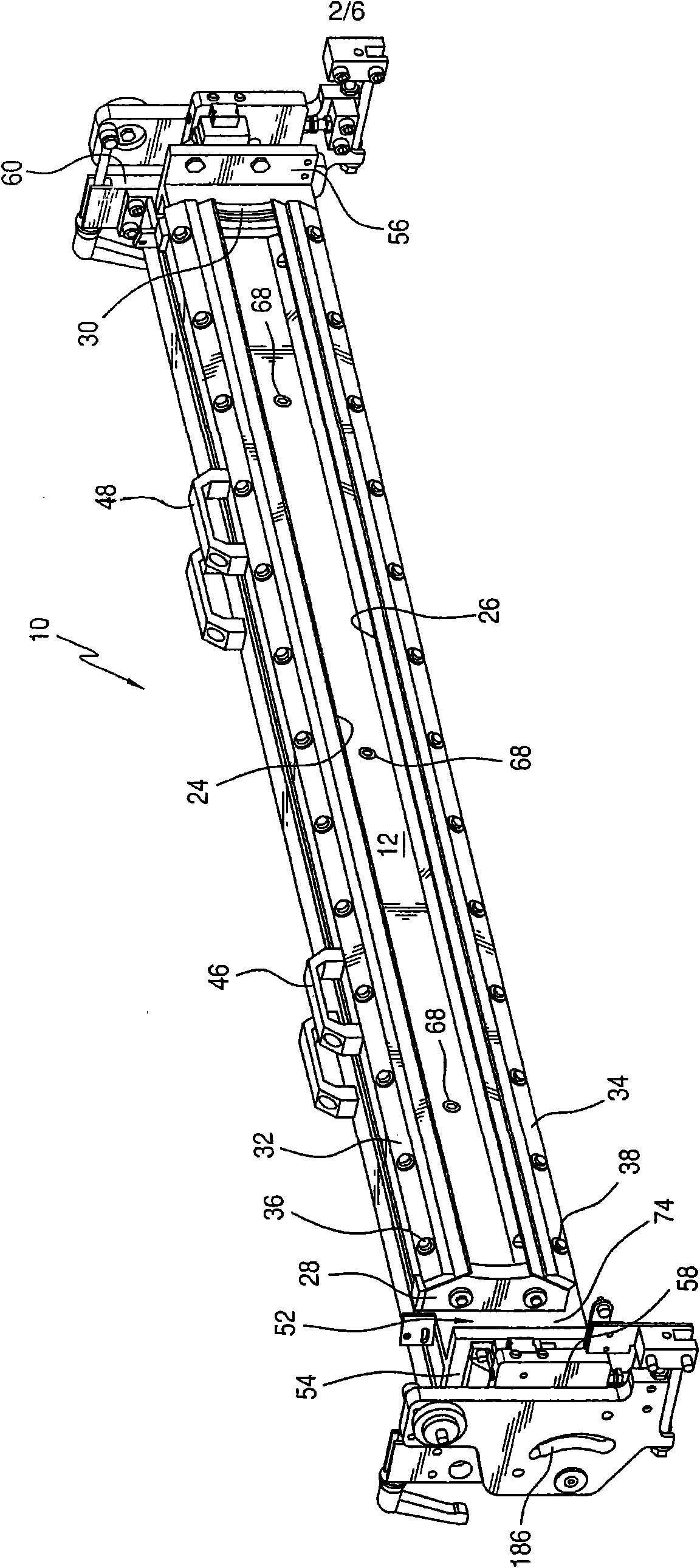

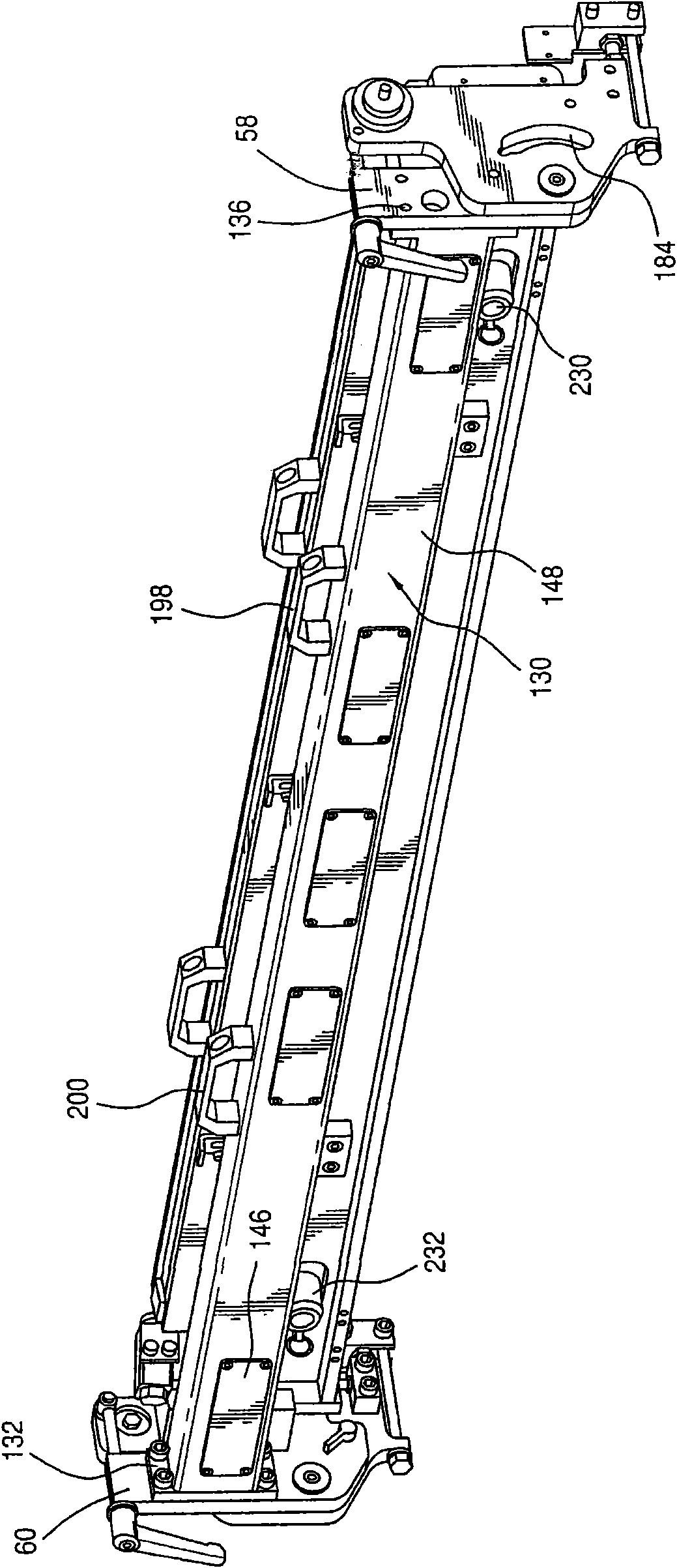

[0038] First refer to figure 1 and combine figure 2 , a preferred embodiment of the doctor blade system according to the invention, indicated overall at 10 , can be seen. It will be appreciated that the doctor blade system, generally indicated at 10, is intended primarily for use in flexographic printing systems or in other commonly known printing systems. In such a system, printing ink is supplied to an ink reservoir 12 within a doctor blade chamber, indicated generally at 14 . Those inks are then transferred to the surface 16 of an ink roller, such as an anilox roller 18 .

[0039] As is well known in the art, the doctor blade chamber, indicated generally at 14, includes an active doctor blade 20 and a closed doctor blade 22, the outer edges 24, 26 of the active doctor blade 20 and the closed doctor blade 22 The surfaces 16 of the anilox rollers 18 are respectively engaged. Such as figure 2 Appropriate end plates 28 and 30 cooperate with the active squeegee 20 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com