Pneumatic tire

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, tire parts, tire treads/tread patterns, etc., which can solve the problems of increased tread pattern noise, poor rigidity balance, and difficulty in improving handling stability on dry roads Reduce tread pattern noise and other issues, achieve the effect of improving handling stability and reducing tread pattern noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

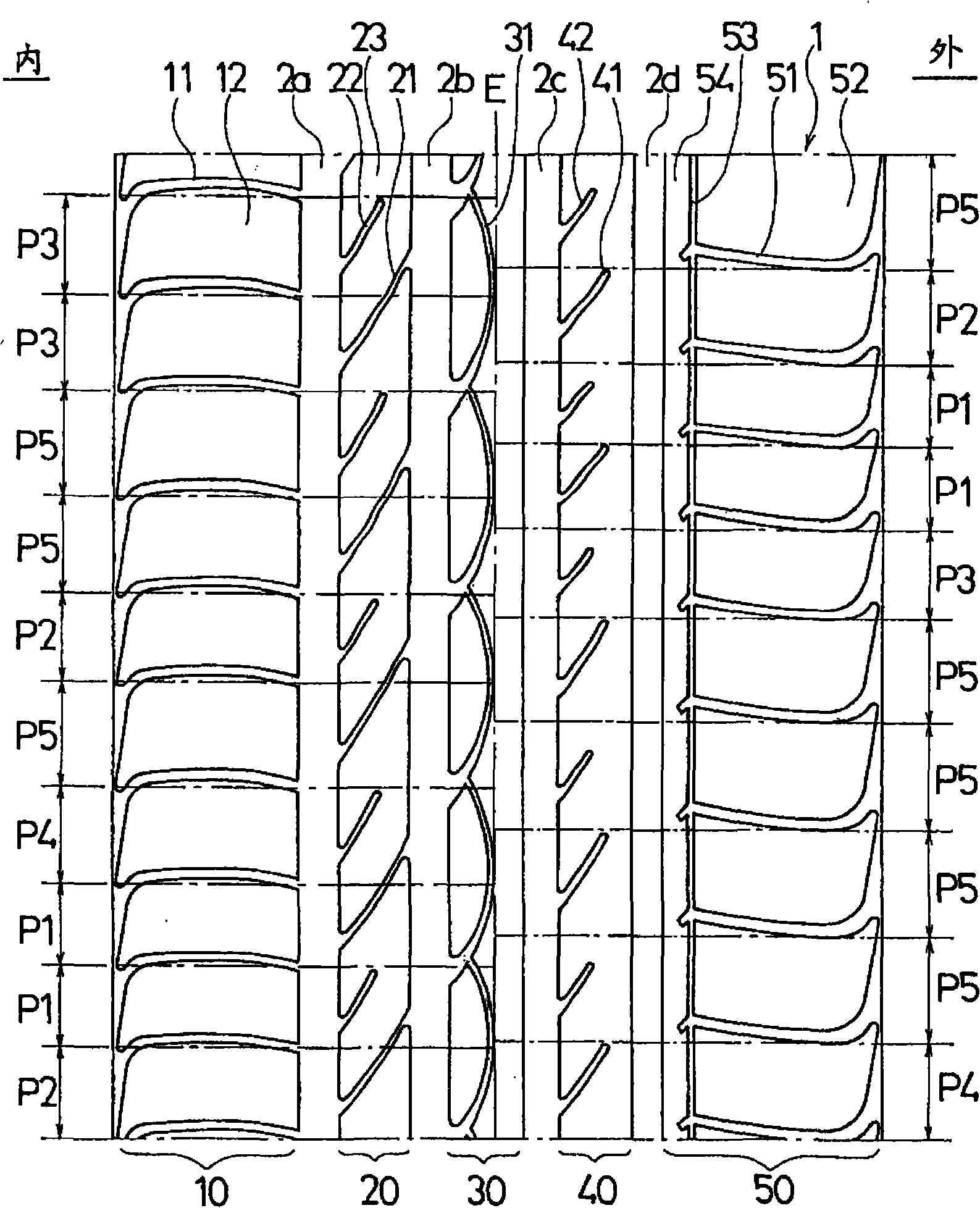

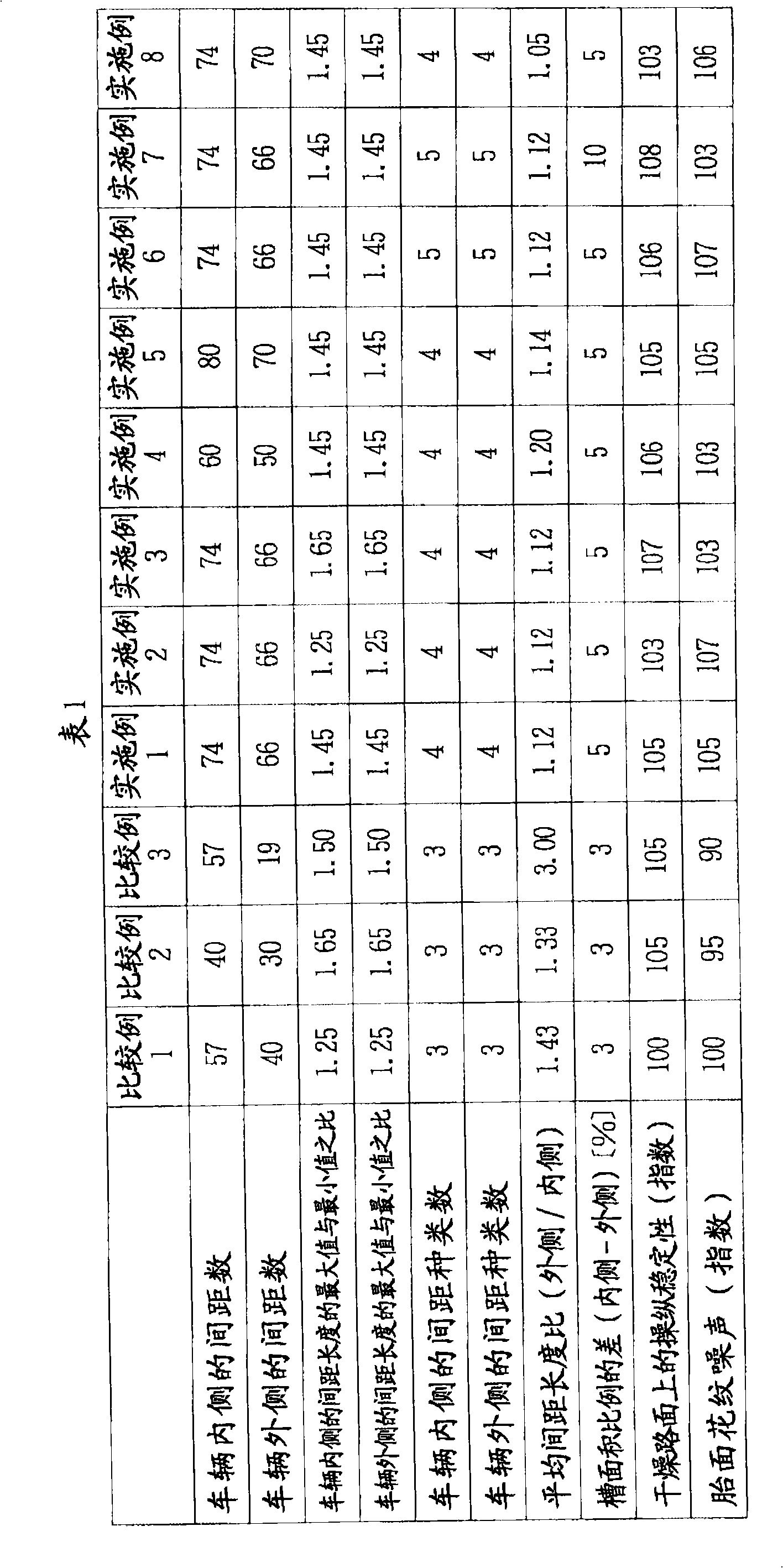

[0041] Make embodiment 1~8 (referring to figure 1 ) and the pneumatic tires of Comparative Examples 1 to 3, wherein the tire size is 275 / 45R20, and the installation direction of the pneumatic tire relative to the inside and outside of the tire of the vehicle is specified, and the pitch of the block elements on the inside of the vehicle is set as shown in Table 1 Number of pitches of block pattern elements on the outside of the vehicle, ratio of minimum pitch length to maximum pitch length of block pattern elements on the vehicle interior, ratio of minimum pitch length to maximum pitch length of block pattern elements on the outside of the vehicle, vehicle The number of pitch types of block elements on the inside, the number of pitch types of block elements on the outside of the vehicle, the ratio of the average pitch length of the block elements on the outside of the vehicle to the average pitch length of the block elements on the inside of the vehicle, The difference between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com