Motor decelerating mechanism of electric bicycle

A technology for electric bicycles and deceleration mechanisms, which is applied to vehicle gearboxes, vehicle components, wheel transmissions, etc., can solve the problems of unsightly appearance and increased volume, and achieve the effect of small volume and large deceleration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

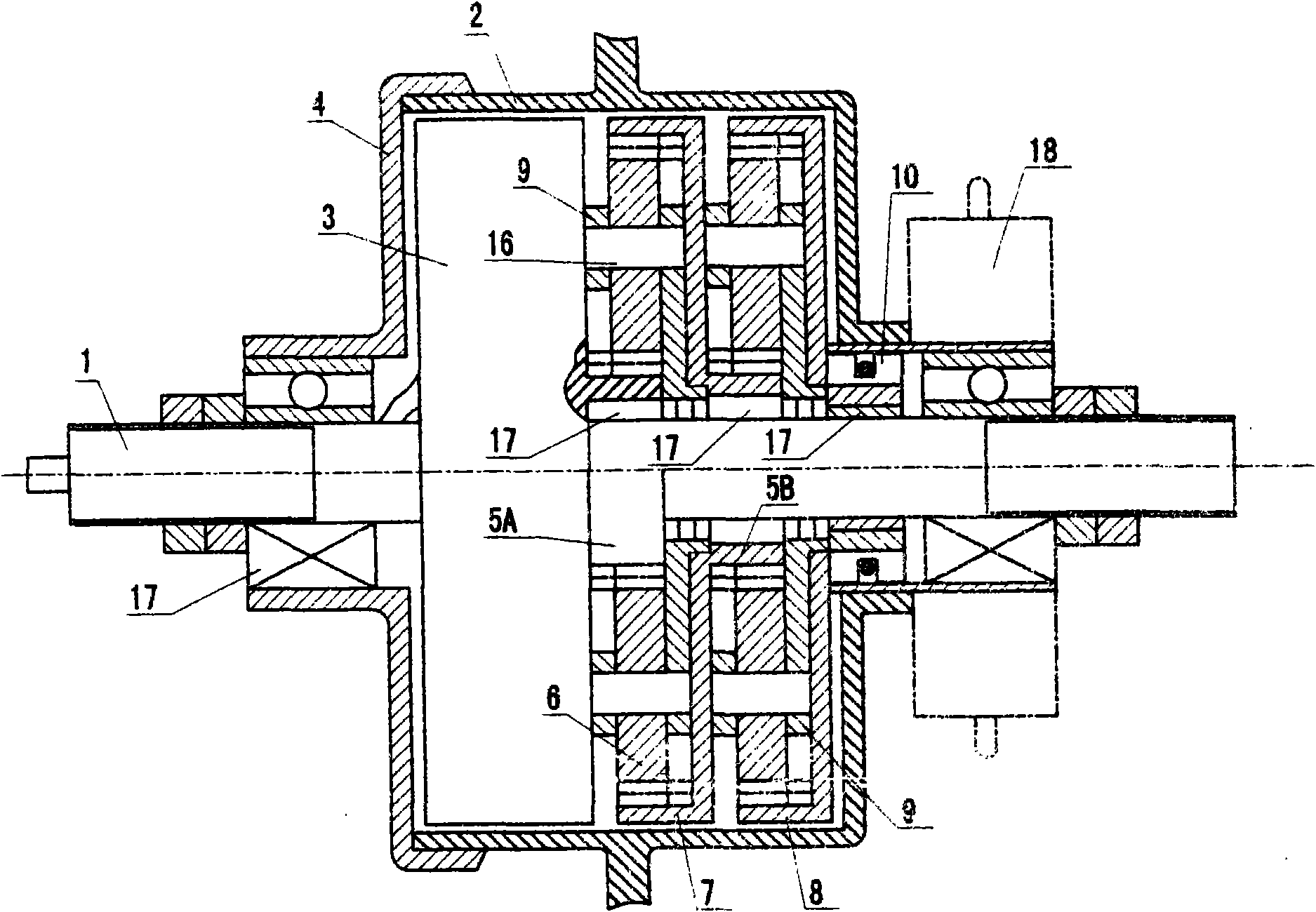

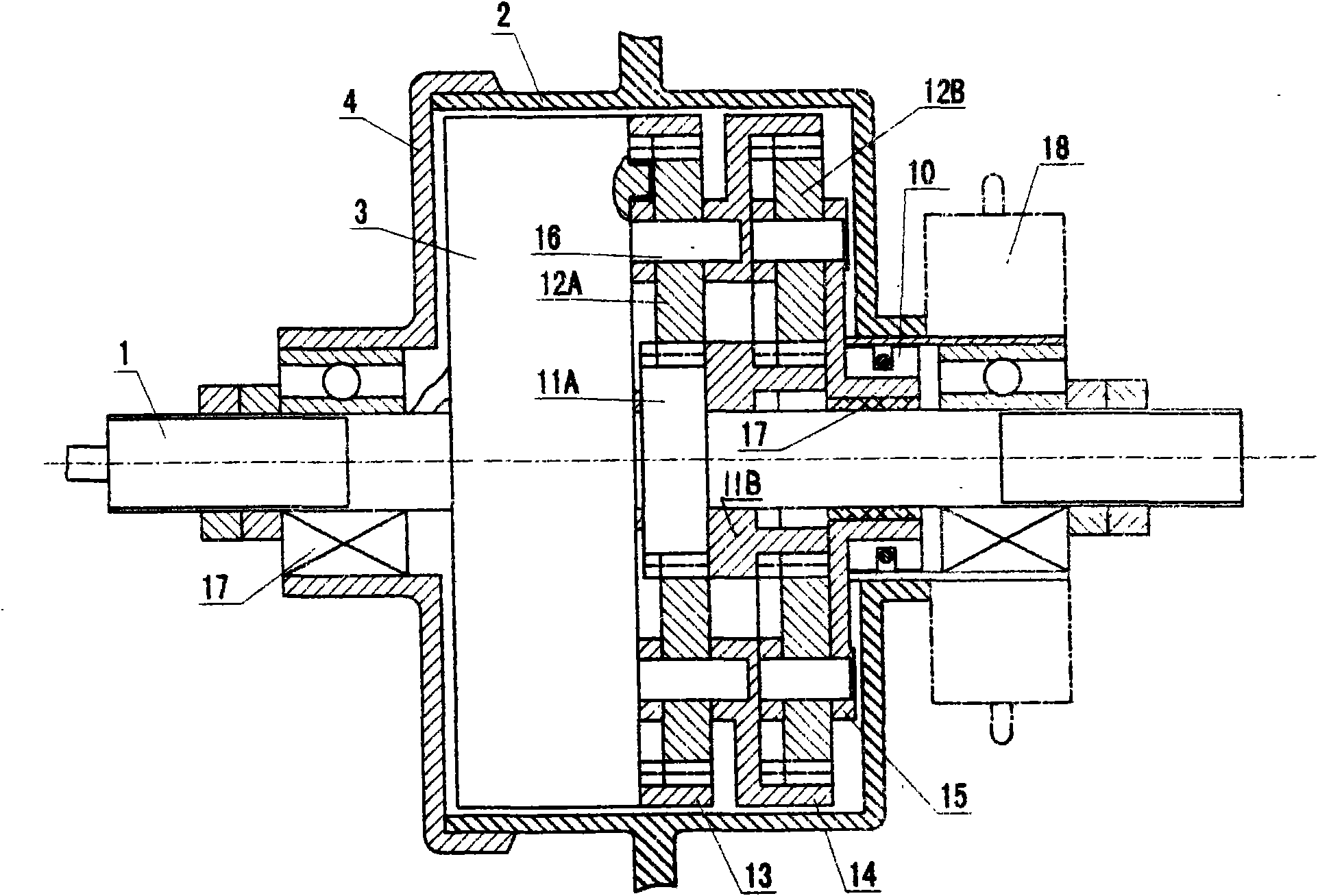

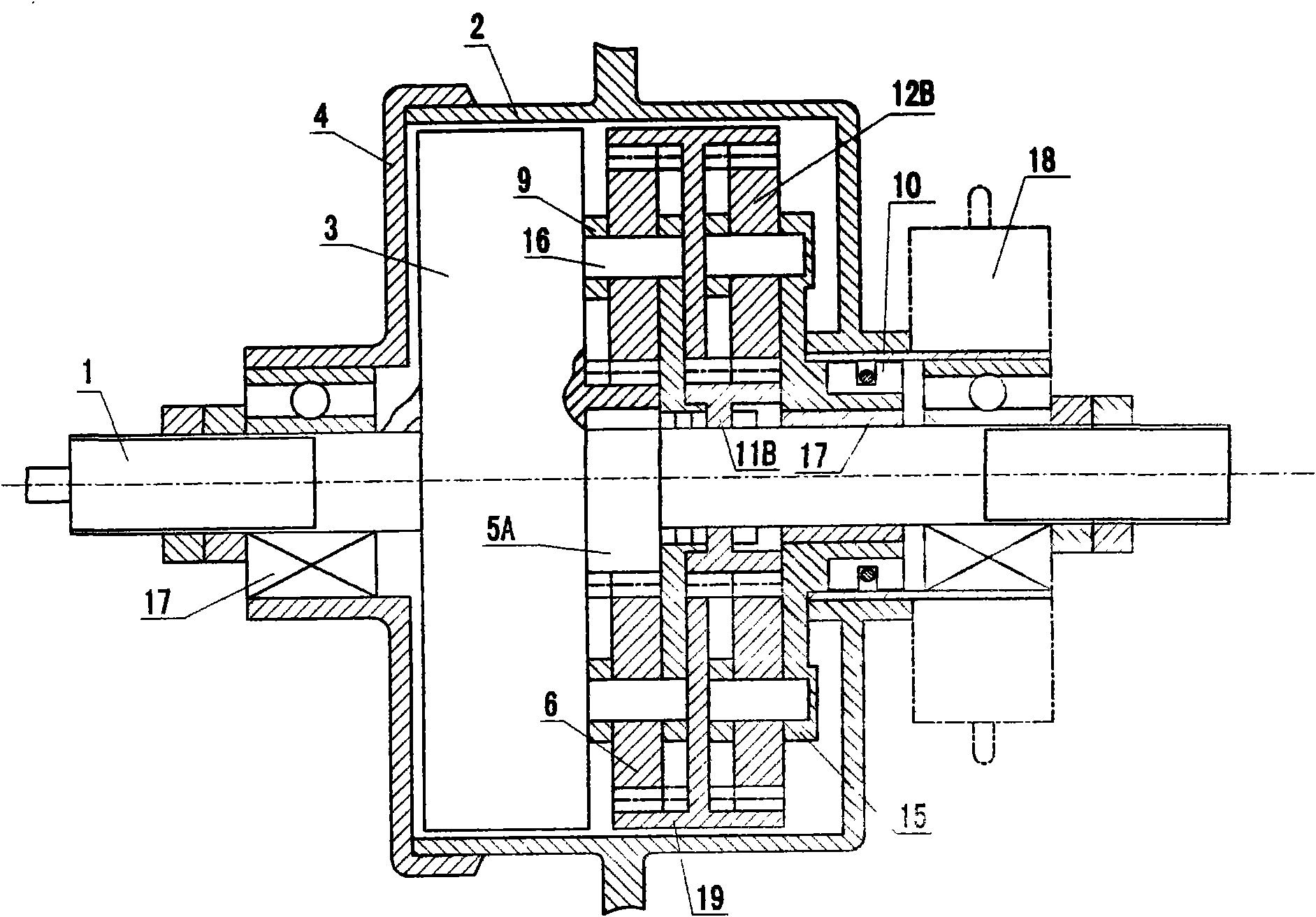

[0017] Describe in detail below in conjunction with accompanying drawing, comprise wheel shaft 1, housing 2, motor 3, cover 4, the 1st stage driving gear 5A, the 2nd stage driving gear 5B, intermediate wheel 6, the first stage with driving gear among the accompanying drawings Stage internal gear 7, second stage internal gear equipped with ratchet or round pin 8, intermediate wheel mount 9, pawl or round pin 10, first stage sun gear 11A, second stage sun gear 11B, planetary gear 12A , planetary gear 12B, internal gear 13 connected with motor rotor, internal gear 14 equipped with planetary gear, planetary gear mount 15 equipped with ratchet or garden pin, intermediate wheel or planetary gear shaft 16, bearing 17, flywheel 18, double internal gear 19, return spring 20.

[0018] figure 1 It is a two-stage reduction mechanism diagram in which the driving gear is installed on the wheel shaft to reduce the internal gear through the intermediate gear. The driving gear 5A connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com