Method and device for the assembly and disassembly of a preplasticizing spindle

A technology for worms and injection molding machines, which is applied in the field of plasticizing worms, and can solve the problems of installation and disassembly requiring a lot of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

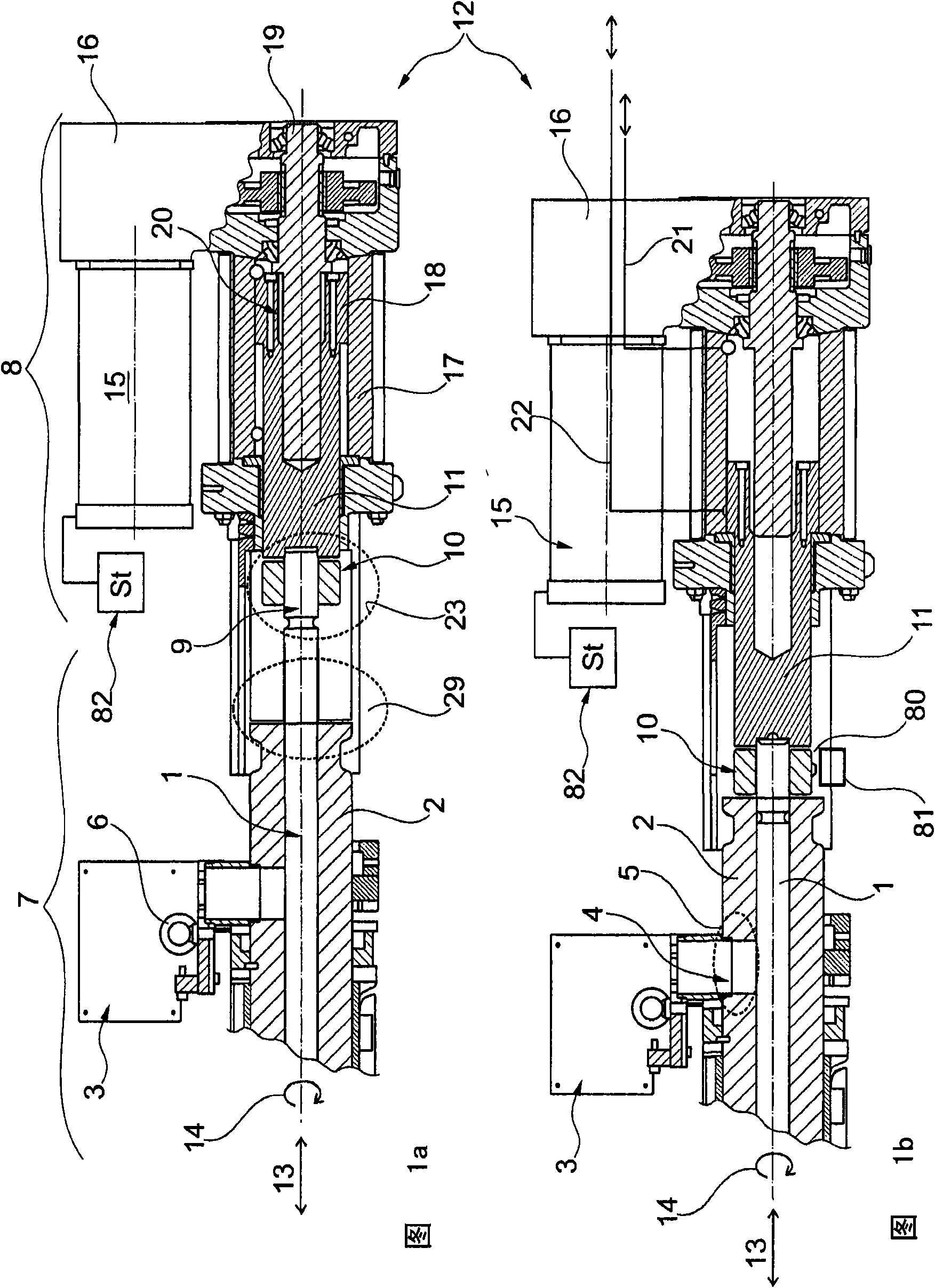

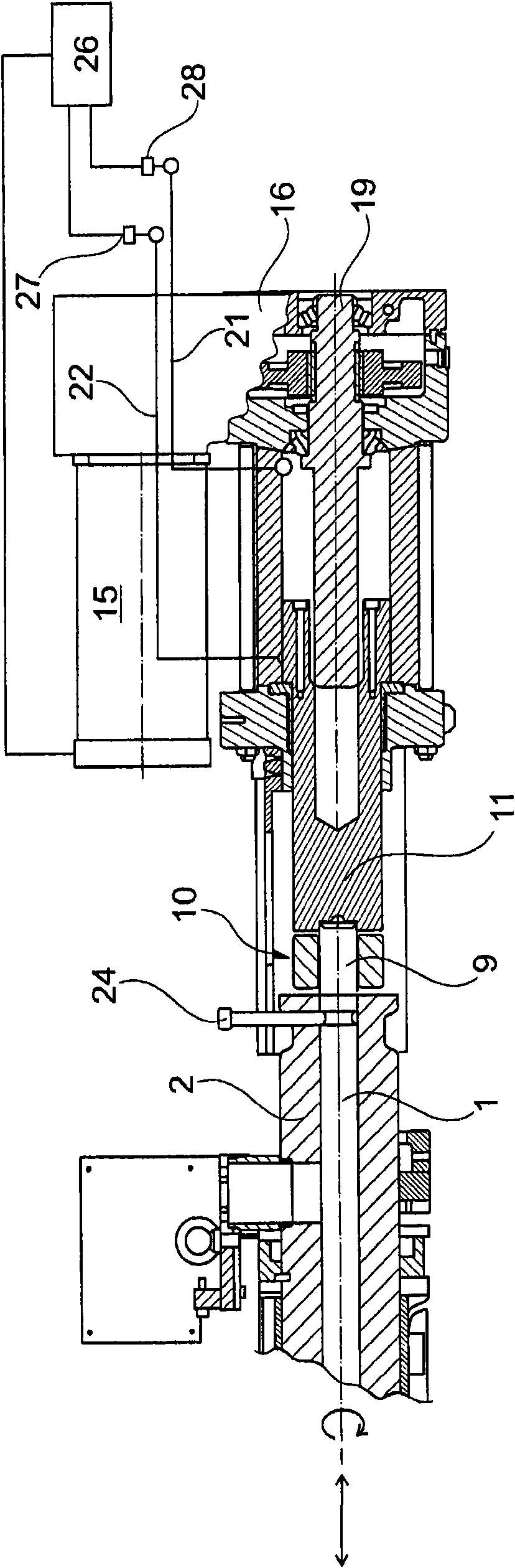

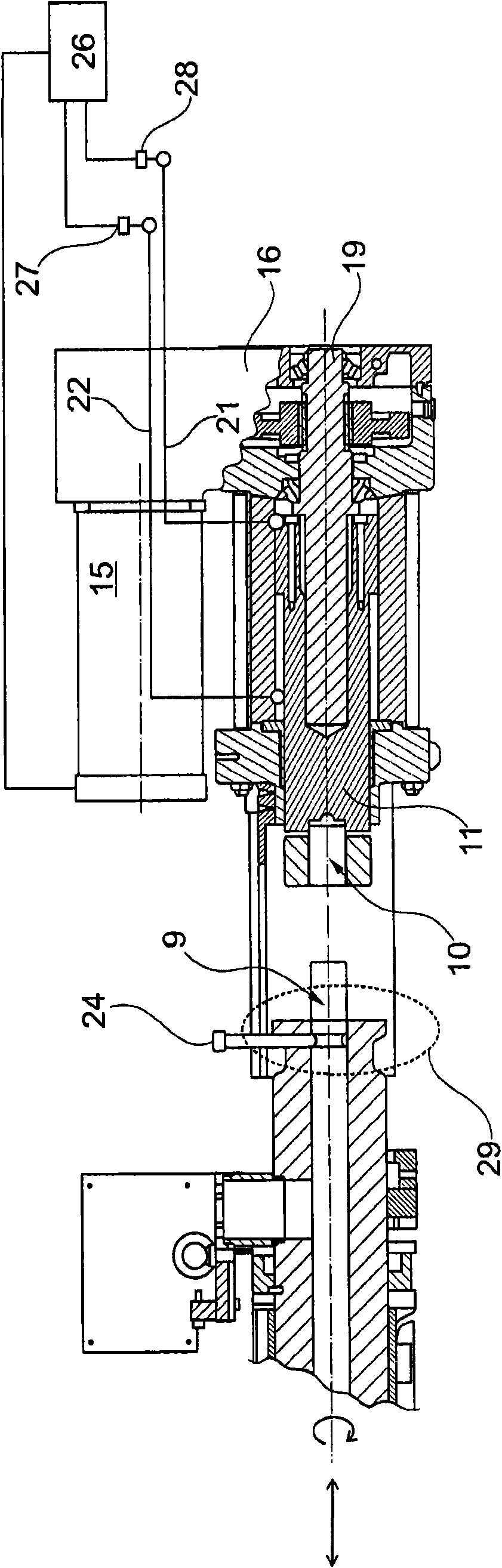

[0046] Refer below Figure 1a and 1b . These two figures show the region of the coupling mechanism in the retracted position of the plasticizing worm 1 ( Figure 1a ) and the case of (1b) in its frontmost position. The plasticizing cylinder 2 is shown on the left side of the figure together with the holding structure 3 for the pellet supply funnel. The still dry pellets are fed into the intake area of the plasticizing screw 1 via the feed opening 4 . A fastening ring 6 is shown here for mounting and dismounting the plasticizing device 7 by means of a machine crane, not shown. In the rear part, the plasticizing worm 1 has a coupling rod 9 which is inserted into a clamping coupling 10 of the drive end 11 of the injection unit 8 . The drive unit 12 is designed for two types of movement of the plasticizing screw 1 , namely a linear movement according to arrow 13 and a rotational movement according to arrow 14 . The rotational movement is produced by a drive motor 15 and a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com