Process for producing curved surface lifting mattress

A technology for raising and lowering mattresses and production processes, applied in mattresses, spring mattresses, filled mattresses, etc., can solve the problems of mattress deformation, easy deformation of the lifting mechanism, affecting the effect of curved surface lifting, etc., to ensure sleep, prevent Low back disease, the effect of alleviating fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

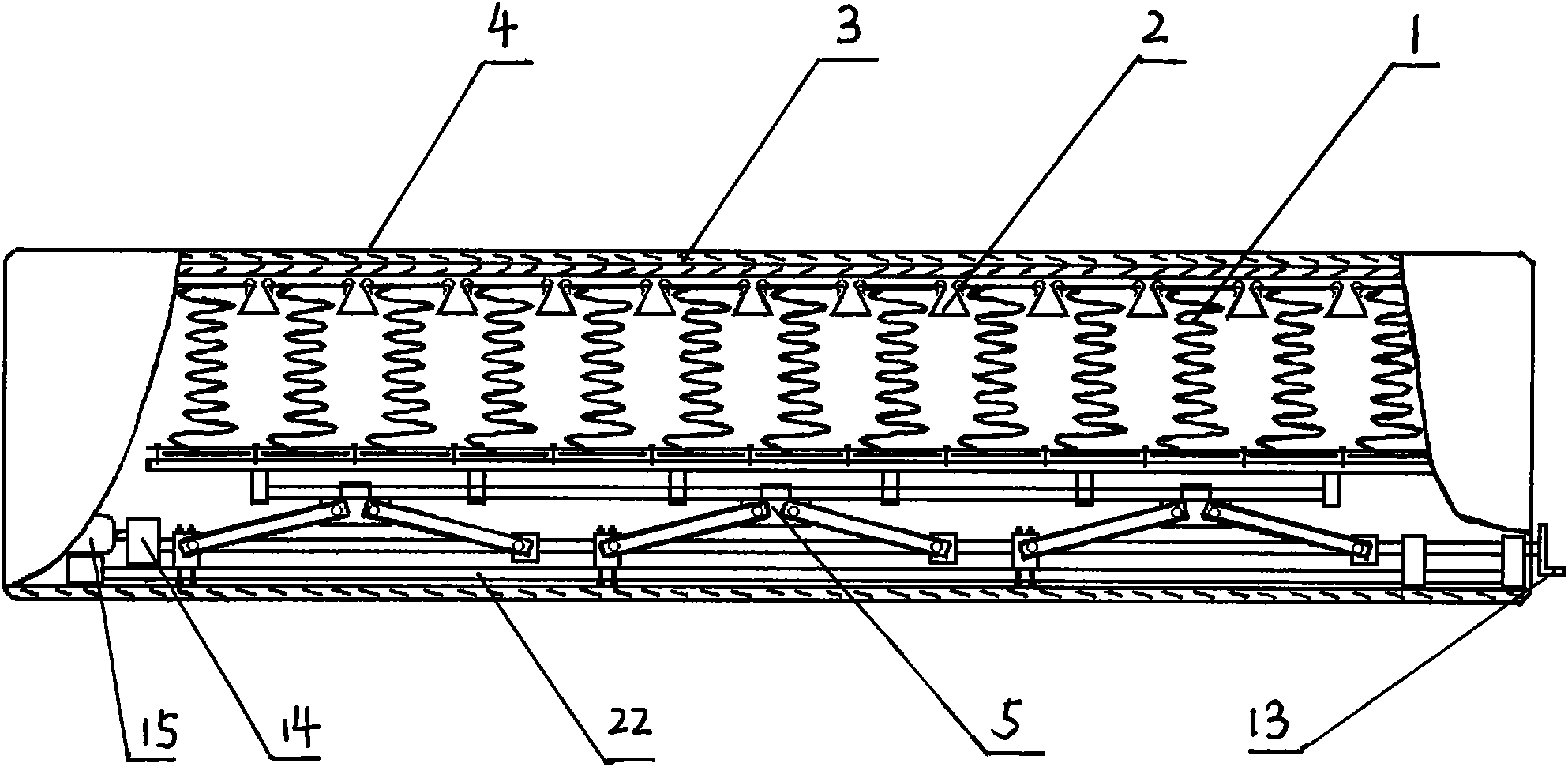

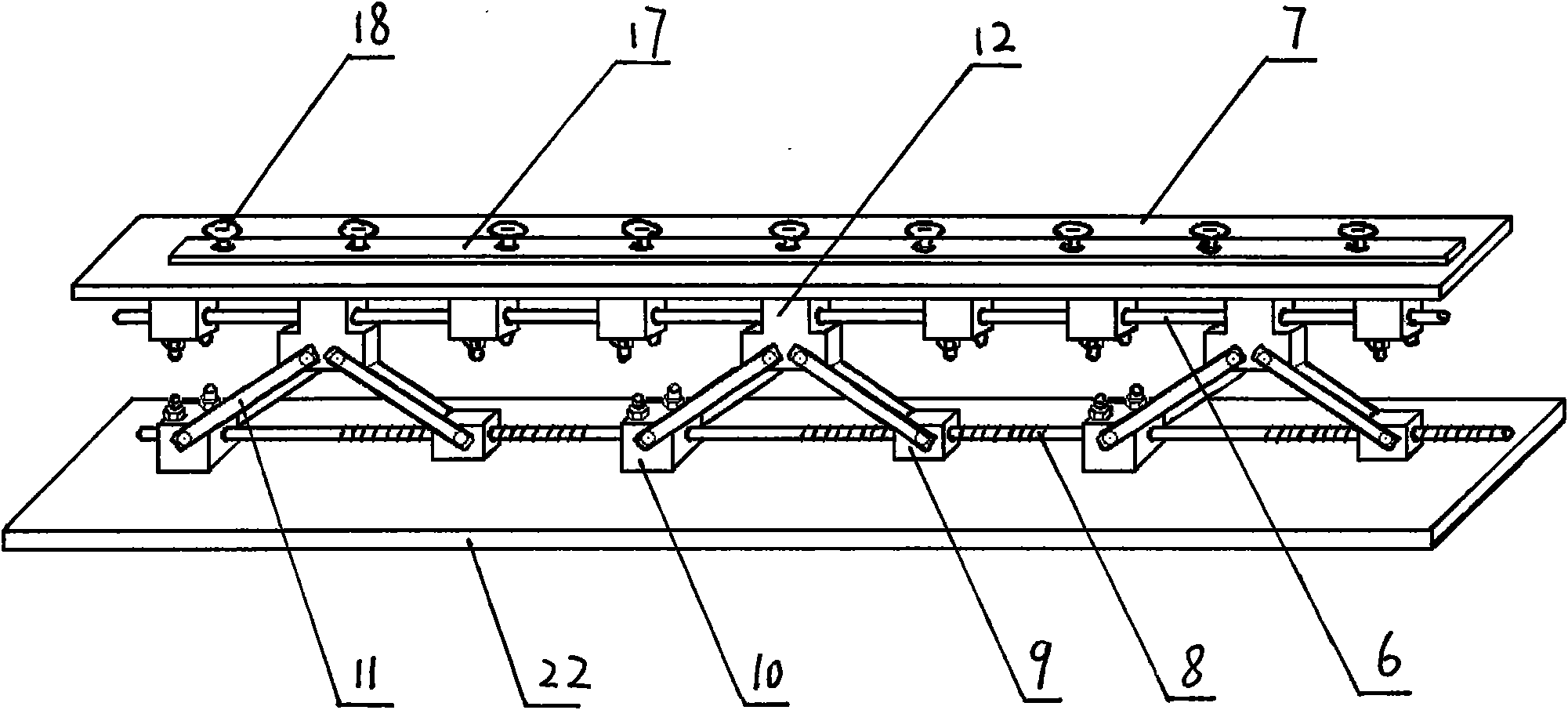

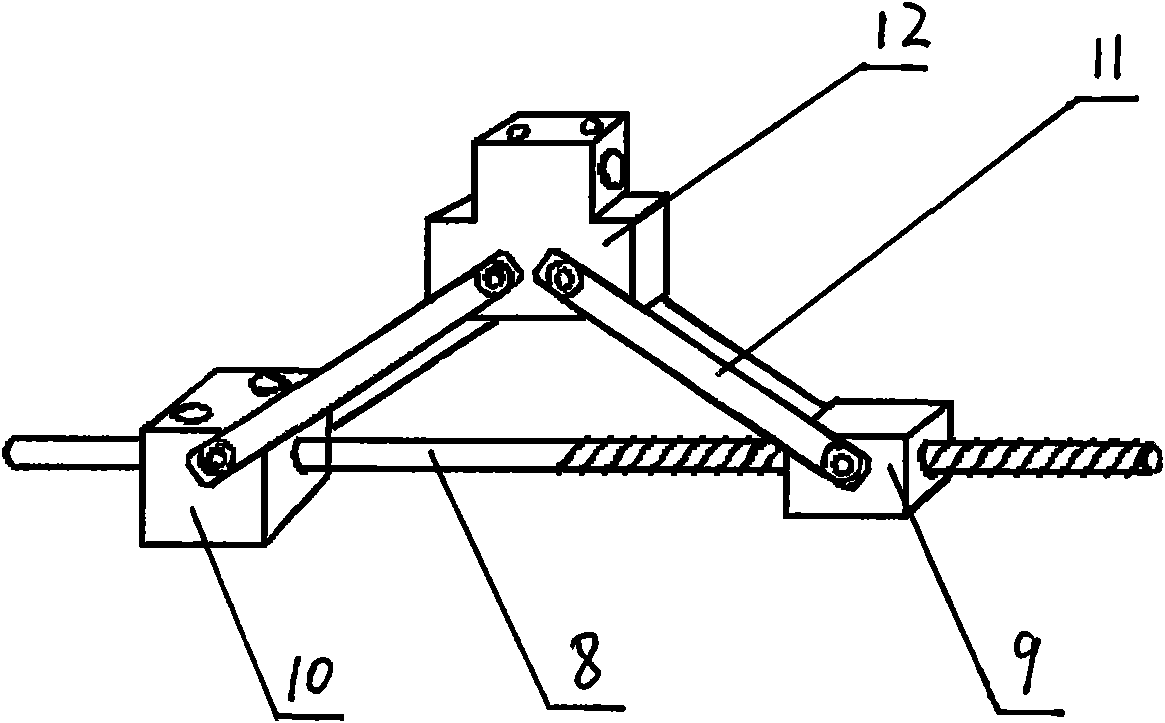

[0016] The curved lifting mattress of the present invention consists of a load-bearing spring 1, a △-shaped opening and closing series spring 2 connected to the load-bearing spring 1, a cushion layer 3 and a surface layer 4 wrapping the load-bearing spring 1, and a lifting mechanism 5 arranged in the mattress. Wherein, the elevating mechanism 5 comprises the elevating slide bar 6, the supporting plate 7 fixed on the elevating slide bar 6, the threaded button 9 and the positioning buckle 10 arranged on the screw mandrel 8, and the positioning buckle 10 is fixed on the backing plate 22, and Buckle 9 and positioning buckle 10 match the lifting arm 11, the lifting arm 11 is connected with the lifting sliding rod 6 through the slider 12, one end of the screw rod 8 is connected with the manual crank 13, and the other end is connected with the reducer 14, and the reducer 14 is connected with the 36V The low-voltage motor 15 is connected. The supporting plate 7 is provided with a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com