Multi-use transfer printing device provided with flexible printing unit and intaglio printing unit simultaneously

A gravure printing and flexo printing technology, applied in the field of multi-purpose transfer printing equipment, can solve the problems of low equipment utilization, high price, and large work space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

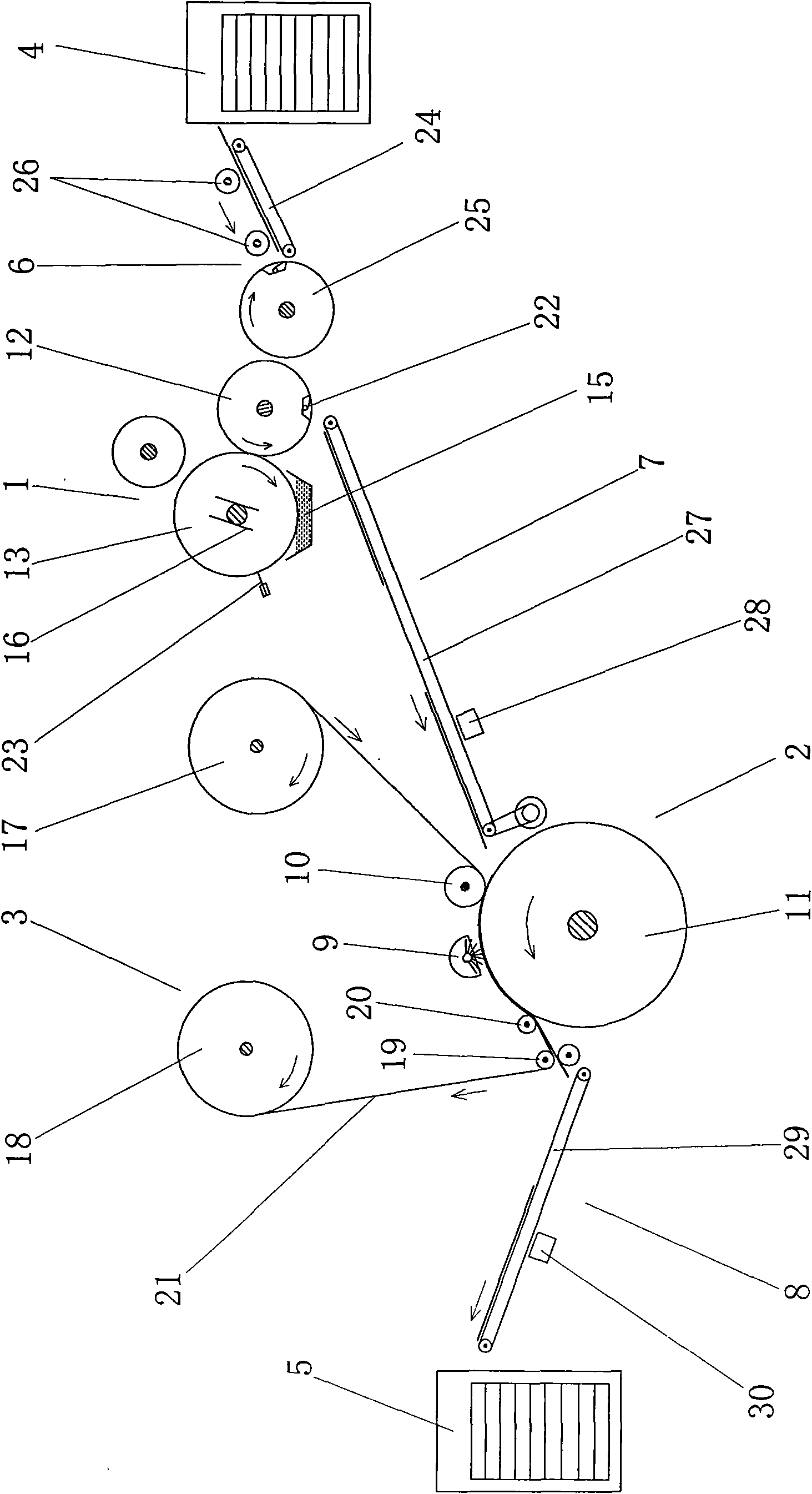

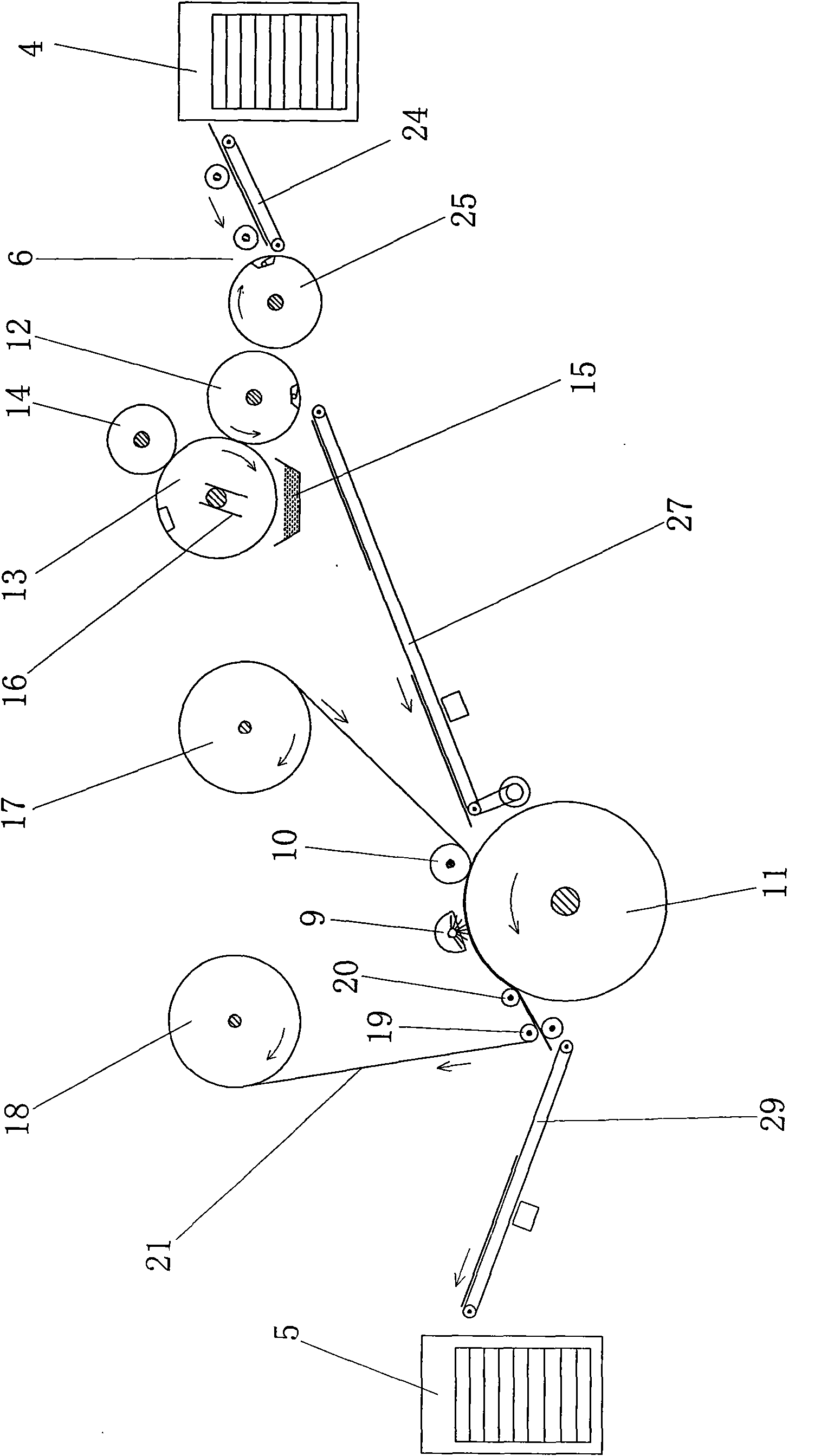

[0018] refer to Figure 1 ~ Figure 2 , the transfer printing equipment with both flexographic and gravure printing units, including a frame and a printing mechanism 1 installed on the frame, a pressing mechanism 2, a pressing film retracting mechanism 3, and a printing material discharging mechanism 4. A printed product receiving mechanism 5, several transmission and transmission fixing mechanisms 5, 7 and 8, and an ultraviolet irradiator 9, wherein the printing mechanism 1 is arranged behind the printing material discharge mechanism 4, and the pressing mechanism 2 is arranged behind the printing material discharge mechanism 4. Behind the mechanism 1, the pressing film retracting mechanism 3 is set near the pressing mechanism 2, and the printed product receiving mechanism 5 is set behind the pressing mechanism 2, and there is a transmission and delivery mechanism between the printing mechanism 1 and the printing material discharge mechanism 4. A transmission and transmission f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap