Bracket crane of multi-purpose underground coal vehicle

A multi-purpose vehicle and cantilever technology, applied in the direction of cranes, etc., can solve the problems of handling, lifting, transportation restrictions, restricting coal mining and transportation, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

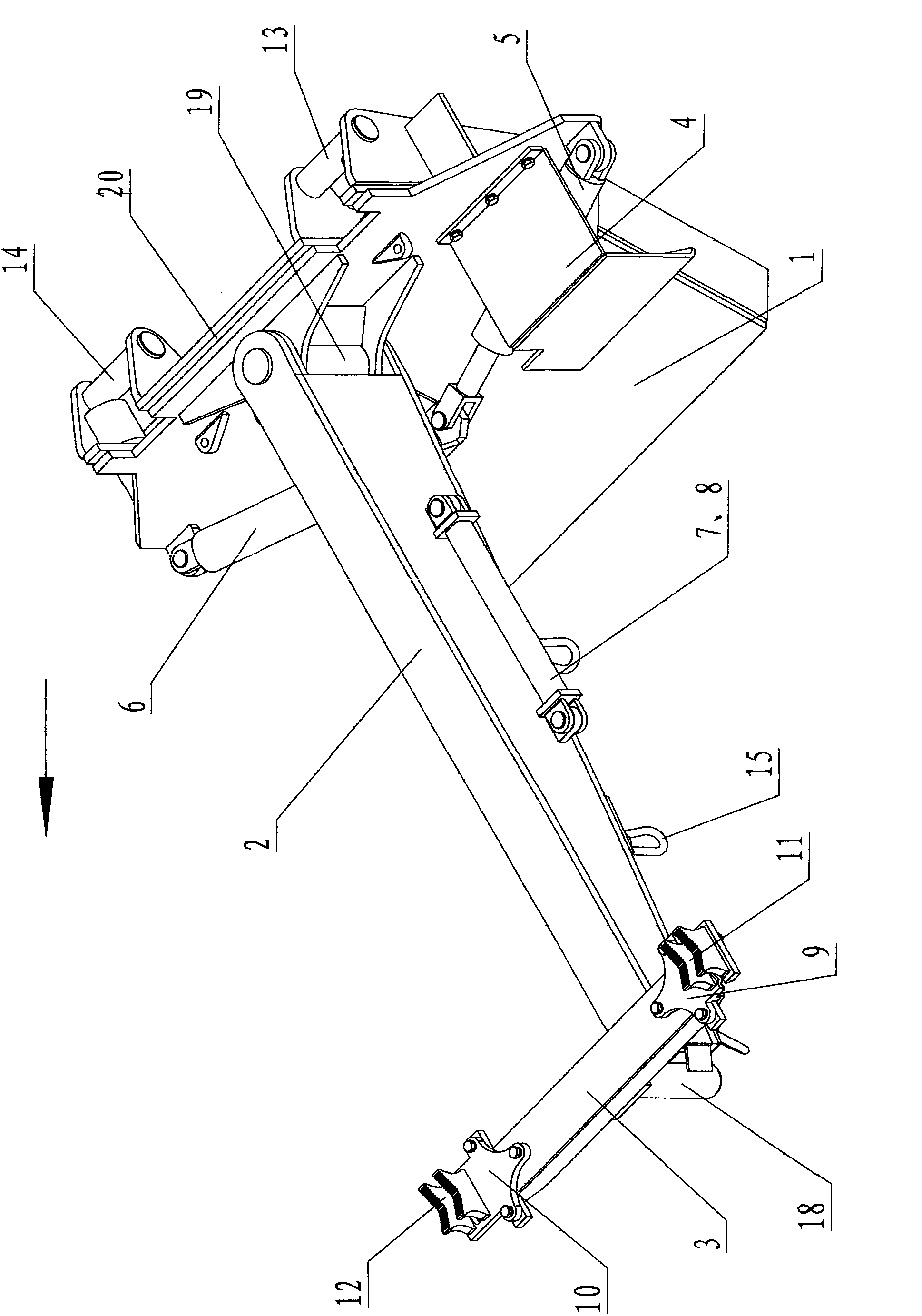

[0020] figure 1 Shown is the overall structure diagram, and the connection relationship of each part must be correct and the installation should be firm.

[0021] The lifting frame is installed on the lifting quick-change mechanism of the utility vehicle, the up and down lifting is completed by the lifting mechanism of the utility vehicle, and the left and right steering is completed by the steering cylinder.

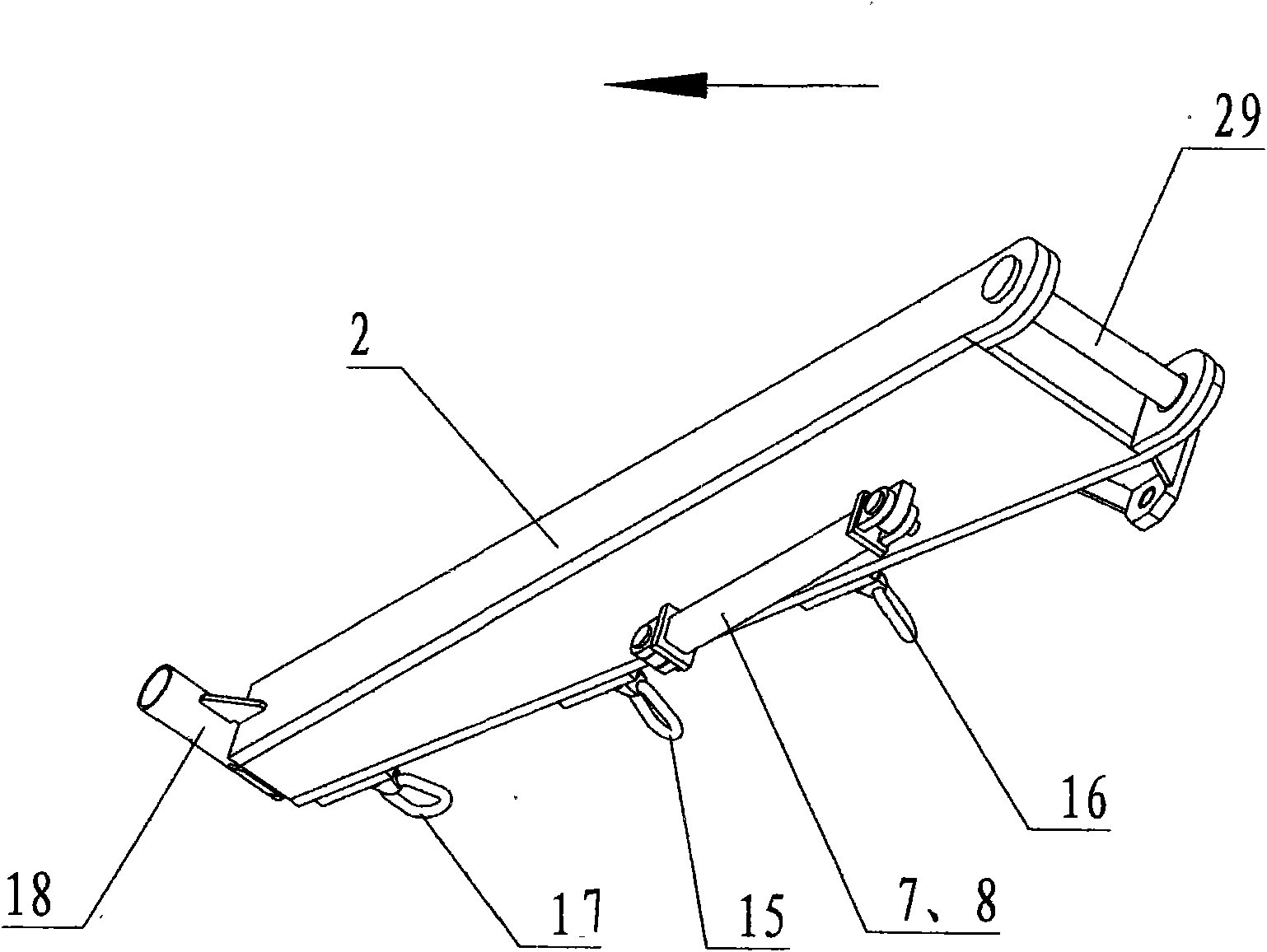

[0022] The lifting frame is connected with the boom through the arm cylinder and the arm shaft, and the boom is connected with the lifting arm through the installation cylinder and the installation shaft.

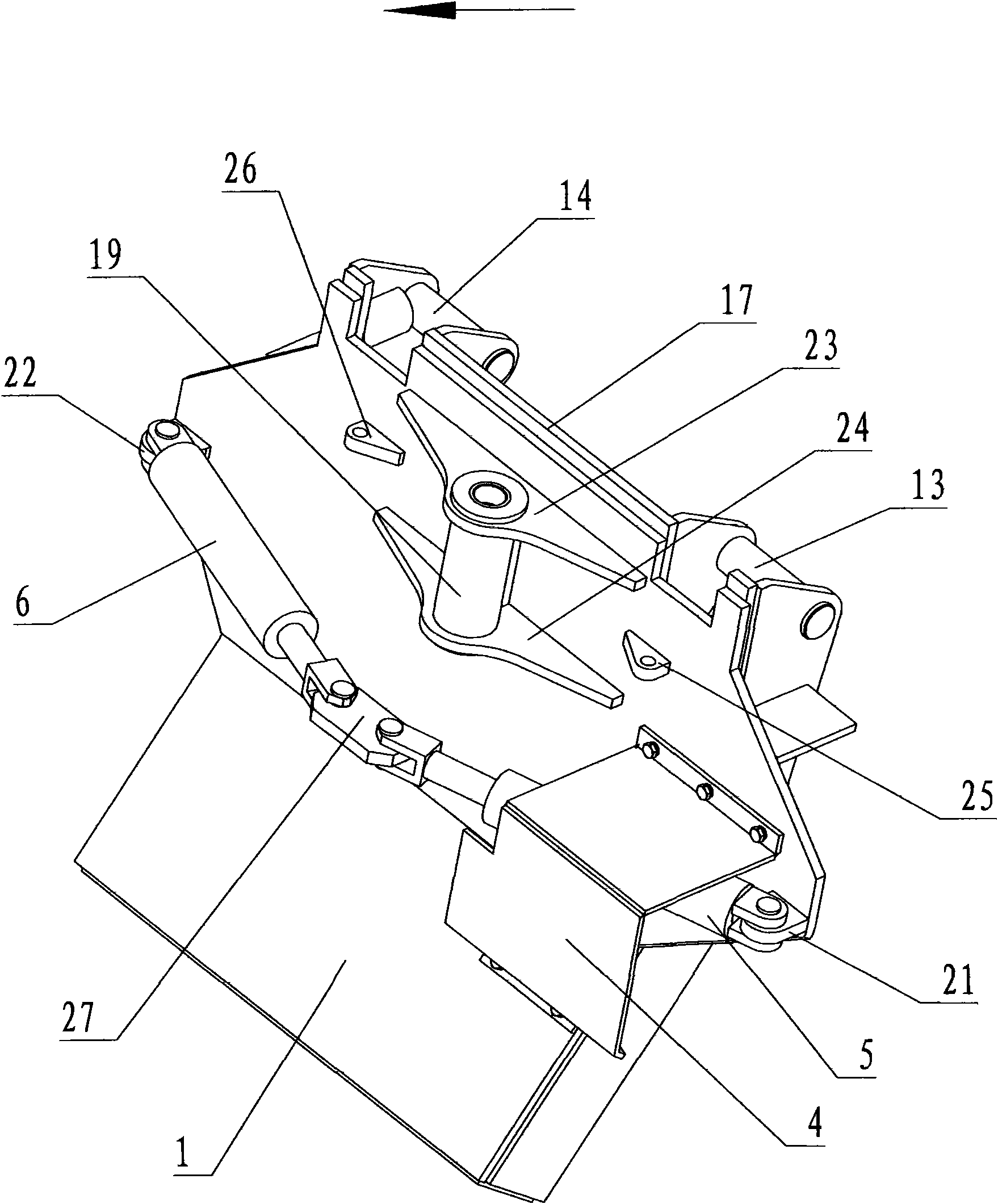

[0023] figure 2 As shown, it is the structural diagram of the lifting frame, which is the upper and lower parts. It must be strong and powerful. The steering cylinder, hinged seat, and hinged frame must be firm. The arm shaft must be strong. go to jail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com