Method for producing ammonium sulphate grain products by using organic caking agent

A technology of organic binder and ammonium sulfate, which is applied in the fields of application, ammonium salt fertilizer, nitrogen fertilizer, etc., can solve the problems of not being able to produce large particles of ammonium sulfate, and achieve the effects of improving product market competitiveness, easy operation, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1 single organic binder produces granular ammonium sulfate

[0020] Polyacrylamide with a molecular weight of 12 million is selected as the organic binder. Ammonium sulfate crystals ≤ 2mm (active ingredients are N: 20.4%, S: 23.58%, H 2 O: 0.8%) is pulverized to 20-200 mesh by a pulverizer; then add the organic binder polyacrylamide solution dissolved in the solvent tank, the ratio of polyacrylamide to ammonium sulfate is 5 / 995, so that the organic binder The mass fraction is 0.5% of the total amount of materials; after that, granulation is carried out by medium-pressure steam spraying, and the granulation temperature is 120°C to 160°C; it is dried by a two-stage dryer, the temperature of the first stage is 220°C to 280°C, and the second stage is dried The temperature is 180 ℃ ~ 240 ℃ for drying; after cooling, use a sieving machine to sieve, select particles with a particle size of 1 ~ 5mm as ammonium sulfate products, pass the inspection, and pack them for de...

example 2

[0021] Example 2 organic binder mixes and prepares granular ammonium sulfate

[0022] The procedure is the same as in Example 1, and polyacrylamide with a molecular weight of 12 million and polyethylene glycol (PEG600) are mixed in a ratio of 1:1 as an organic binder. The binder accounts for 1% of the total mass fraction, is dissolved and mixed evenly and added to the granulator, and the ratio and process operation parameters are controlled to obtain qualified granular ammonium sulfate products.

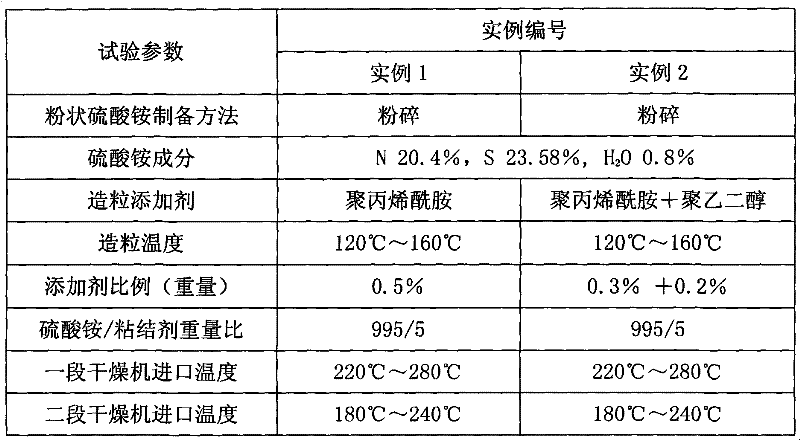

[0023] The following table lists the process parameters and product quality details

[0024] Table 1 list of process parameters

[0025]

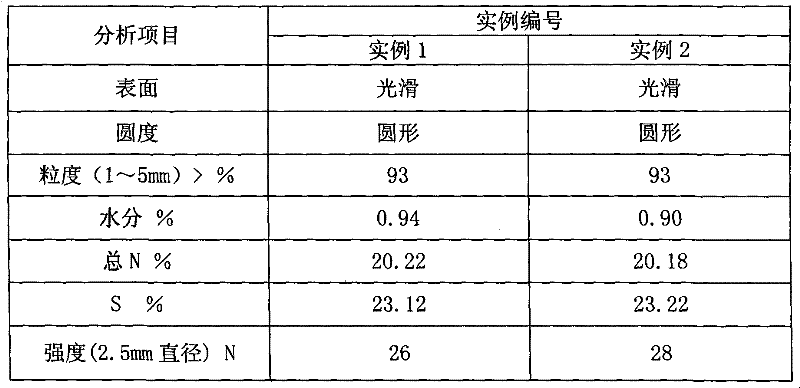

[0026] Table 2 List of final product quality indicators

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com