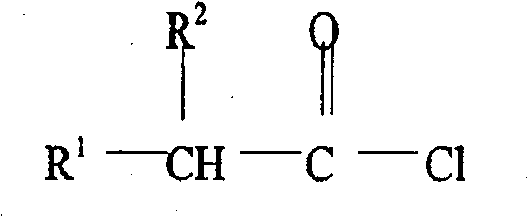

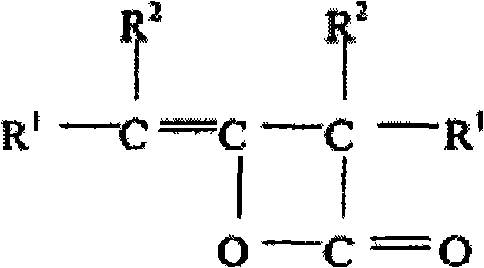

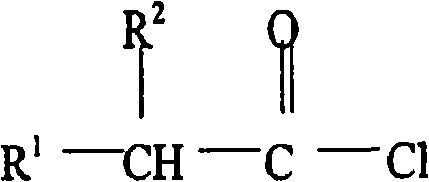

Alkyl ketene, preparation method and application thereof

A technology of alkyl ketene and straight-chain alkyl, applied in the field of alkyl ketene and its preparation and application, can solve problems such as complex process, achieve simple process, high dimer content, and good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of alkyl ketene dimers:

[0027] Add 120 grams of triethanolamine to a 1000ml reactor, heat up to 55°C, and add 400 grams of C 16 Saturated fatty acid chloride, the dropwise addition time is 2 hours. After the dropwise addition was completed, the mixture was kept at 55° C. for 3 hours. Add 400 grams of 70 DEG C deionized water under stirring then, and continue to stir for 10 minutes, stop stirring, remove the bottom triethanolamine hydrochloride aqueous solution (this process temperature remains on 70 DEG C) after 30 minutes. Add 400 grams of 70° C. deionized water under stirring, and continue to stir for 10 minutes, stop stirring, and remove the bottom water after 30 minutes (the process temperature remains at 70° C.). The prepared sample was transferred to a 1000ml round-bottomed flask while hot, and the remaining moisture was evaporated with a rotary evaporator RV 10 digital display type V (IKA company), and the obtained sample passed through a 200-mesh...

Embodiment 2

[0029] Preparation of alkyl ketene dimers:

[0030] Add 140 grams of triethanolamine and 70 grams of diethanolamine to a 2000ml reactor, heat up to 85°C, and add 300 grams of C 22 Saturated fatty acid chloride, the dropwise addition time is 0.5 hours. After completion of the dropwise addition, the mixture was kept at 85° C. for 0.5 hours. Add 600 grams of 80 DEG C of deionized water under stirring then, and continue to stir for 15 minutes, stop stirring, remove bottom triethanolamine hydrochloride and diethanolamine hydrochloride aqueous solution (this process temperature remains on 80 DEG C) after 20 minutes. Add 600 grams of 70° C. deionized water under stirring, and continue to stir for 15 minutes, stop stirring, and remove the bottom water after 20 minutes (the process temperature remains at 80° C.). The prepared sample was transferred to a 1000ml round-bottomed flask while hot, and the remaining moisture was evaporated with a rotary evaporator RV 10 digital display type...

Embodiment 3

[0032] Add 75 grams of triethanolamine and 75 grams of diethanolamine to a 2000ml reactor, heat up to 80°C, and add 150 grams of C 20 Saturated fatty acid chloride and 150 g C 18 Saturated fatty acid chloride, the dropwise addition time is 1.5 hours. After completion of the dropwise addition, the mixture was kept at 80° C. for 2.0 hours. Then add 450 grams of 75 DEG C deionized water under stirring, and continue to stir for 12 minutes, stop stirring, and remove bottom triethanolamine hydrochloride and diethanolamine hydrochloride aqueous solution (this process temperature remains on 75 DEG C) after 25 minutes. Add 400 grams of 75° C. deionized water under stirring, and continue to stir for 12 minutes, stop stirring, and remove the bottom water after 25 minutes (the process temperature remains at 75° C.). The prepared sample was transferred to a 1000ml round-bottomed flask while hot, and the remaining moisture was evaporated with a rotary evaporator RV 10 digital display type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com