A kind of preparation method of hydrogenated dimer acid

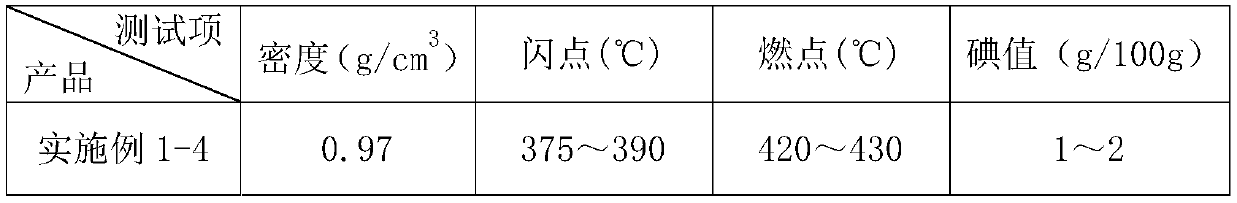

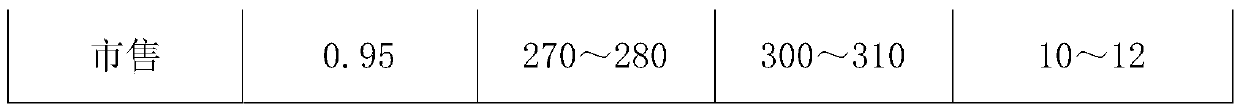

A technology for hydrogenating dimer acid and dimer acid, which is applied in the preparation of organic compounds, the preparation of carboxylates, chemical instruments and methods, etc., can solve the problems of dark color, high iodine value, low ignition point, etc. The effect of high content, strong thermal stability and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 discloses a kind of preparation method of hydrogenated dimer acid, comprises following preparation steps:

[0020] Step 1, the preparation of crude dimer acid

[0021] Add cottonseed oil fatty acid, dimethylformamide, deionized water, sodium carbonate and aluminum oxide into the reaction kettle, blow in nitrogen, pressurize to 2MPa at 180°C, stir for 3h, add 4mol / L phosphoric acid solution , stirred for 30 minutes, then heated up to 220 ° C, gradually reduced the pressure in the reactor, and discharged the water vapor in the reactor, and when the pressure in the reactor was reduced to 1 atm, stopped heating, left to cool, and obtained the crude dimer acid;

[0022] Step 2, the preparation of refined dimer acid

[0023] Add the crude dimer acid prepared in step 1 into the molecular still, adjust the vacuum in the molecular still, control the vacuum at 0.1Pa, raise the temperature to 100-120°C for molecular distillation, and collect the molecular still after...

Embodiment 2

[0027] Embodiment 2 discloses a kind of preparation method of hydrogenated dimer acid, comprises following preparation steps:

[0028] Step 1, the preparation of crude dimer acid

[0029] Add cottonseed oil fatty acid, dimethylformamide, deionized water, sodium carbonate and boron trifluoride into the reaction kettle, blow in nitrogen, pressurize to 3MPa at 210°C, stir for 4h, add 4mol / L phosphoric acid solution, stirred for 30 minutes, then heated up to 230°C, gradually reduced the pressure in the reactor, and discharged the water vapor in the reactor, and when the pressure in the reactor was reduced to 1 atm, stopped heating, left to cool, and obtained the crude dimer acid;

[0030] Step 2, the preparation of refined dimer acid

[0031] Add the crude dimer acid prepared in step 1 into the molecular still, adjust the vacuum in the molecular still, control the vacuum at 0Pa, raise the temperature to 120°C for molecular distillation, and collect the residue in the molecular st...

Embodiment 3

[0035] Embodiment 3 discloses a kind of preparation method of hydrogenated dimer acid, comprises the following preparation steps:

[0036] Step 1, the preparation of crude dimer acid

[0037] Add cottonseed oil fatty acid, dimethylformamide, deionized water, sodium carbonate and tin tetrachloride into the reaction kettle, blow in nitrogen, pressurize to 2.5MPa at 190°C, stir for 3.5h, add 4mol / L The phosphoric acid solution was stirred for 30 minutes, then heated to 225°C, the pressure in the reactor was gradually reduced, and the water vapor in the reactor was discharged. When the pressure in the reactor was reduced to 1 atm, the heating was stopped, and the crude dimer was obtained by standing for cooling. acid;

[0038] Step 2, the preparation of refined dimer acid

[0039] Add the crude dimer acid prepared in step 1 into the molecular still, adjust the vacuum in the molecular still, control the vacuum at 0.2 Pa, raise the temperature to 110°C for molecular distillation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com