Producing method for high softening point polymer resin

A technique for polymerizing rosin and a production method, which is applied in the production field of high softening point polymerized rosin, can solve problems such as product quality defects, low dimer content, harsh production environment, etc., and achieve good product quality, high dimer content, The effect of reducing the degree of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

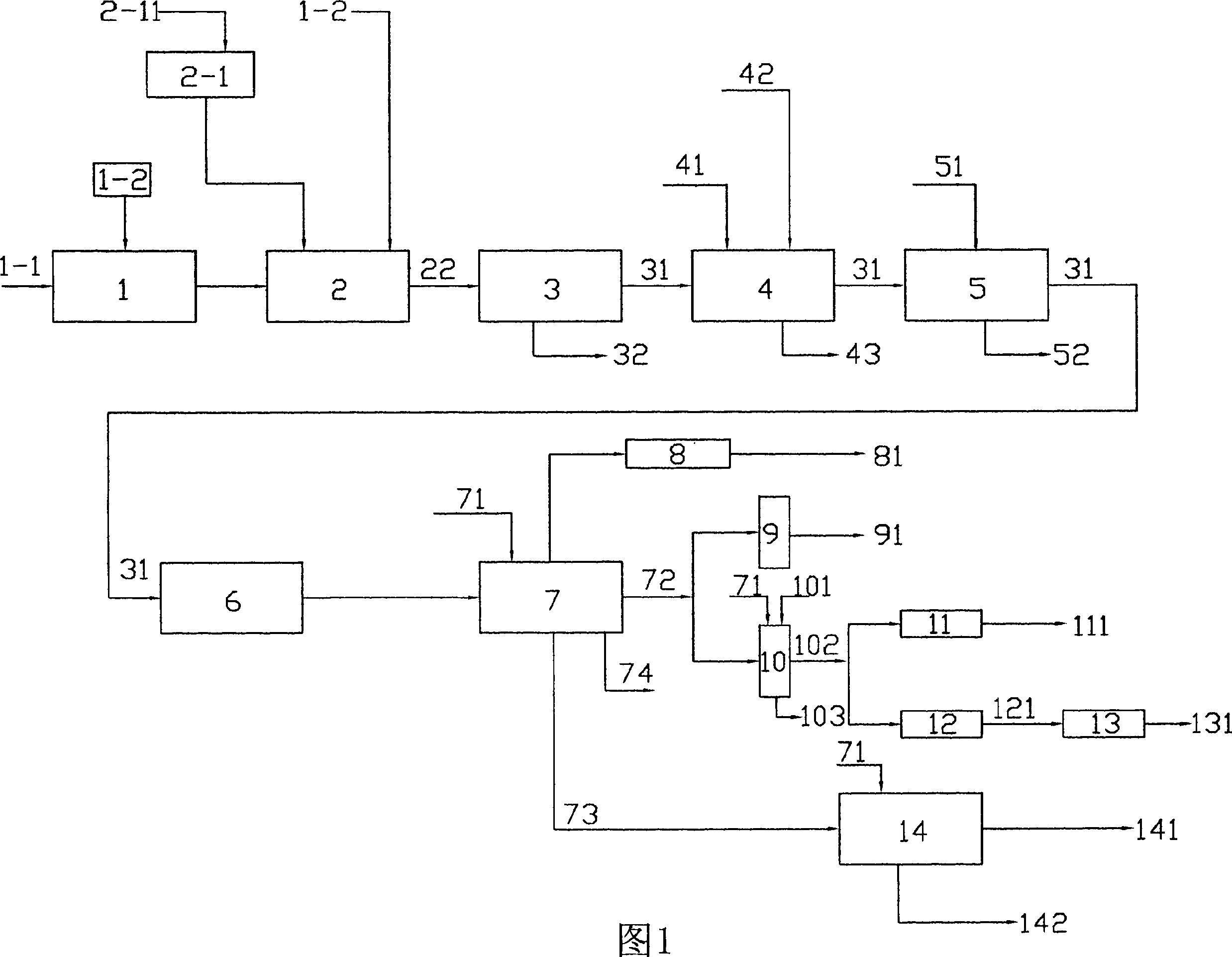

[0021] As shown in the accompanying drawings, in the production device shown in Figure 1, implement the production method of the present invention, its main points, process conditions and product performance indicators are as follows.

[0022] 1. the key points of production method of the present invention:

[0023] (1) take gum rosin as raw material;

[0024] (2) The solvent used for the polymerization reaction is No. 200 gasoline;

[0025] (3) dripping 95% concentrated sulfuric acid under the cooling of jacketed reactor water bath to carry out polymerization reaction;

[0026] (4) neutralize the polymerized rosin reaction solution with solid ammonium carbonate;

[0027] (5) washing the clarified polymerized rosin neutralizing solution with hot water;

[0028] (6) Distilling the washed polymerized rosin liquid to separate crude 95 polymerized rosin with a softening point of 90°C to 100°C; or to separate crude 145 polymerized rosin with a softening point of 141°C to 150°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com