Electrolyzer liner dismounting structure of electrolyzer centralized overhaul workshop

An electrolytic cell and workshop technology, applied in the field of electrolytic cell lining removal structure, can solve problems such as large dust and environmental pollution, and achieve the effect of improving repair ability, ensuring repair quality, and protecting and repairing the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

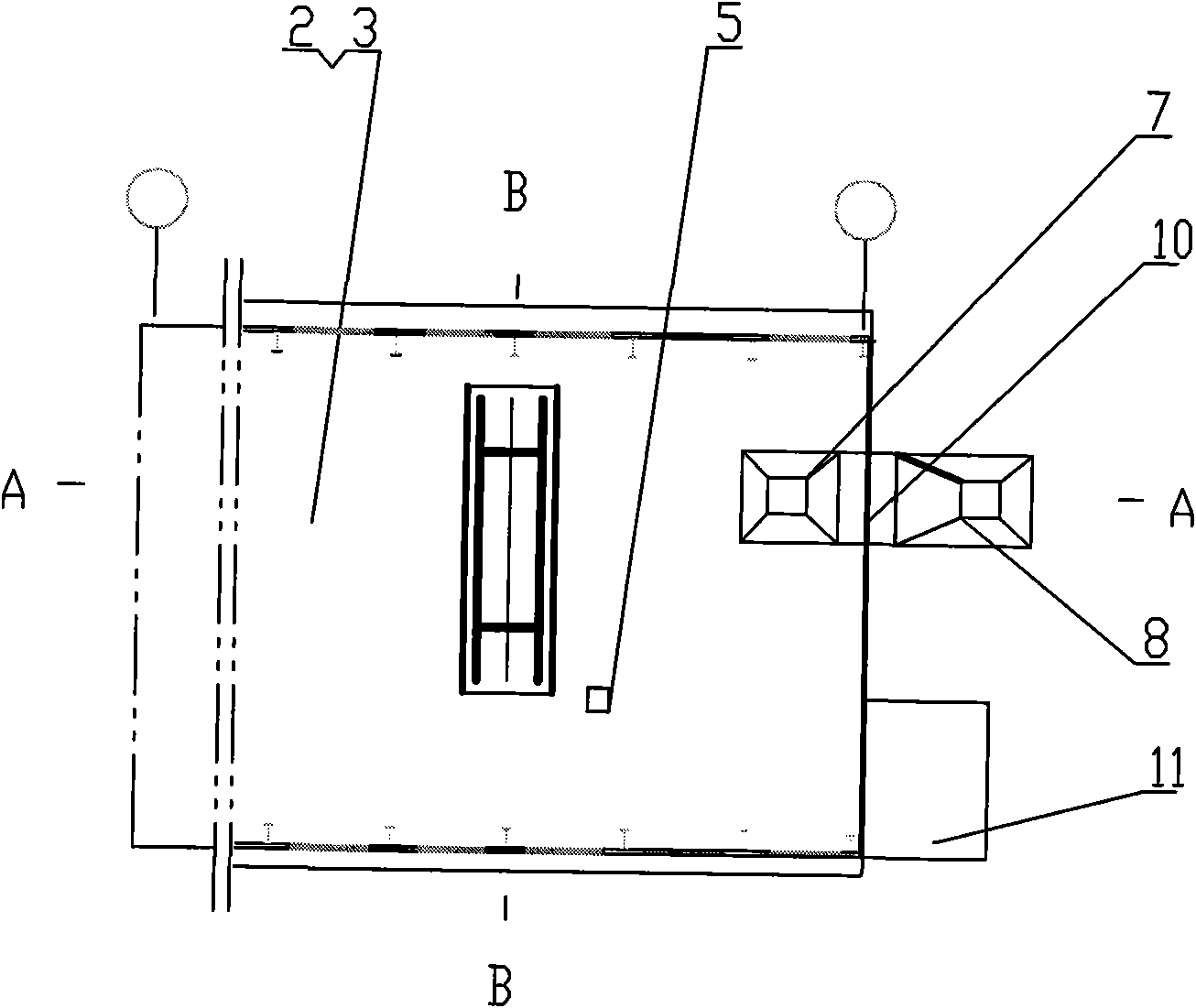

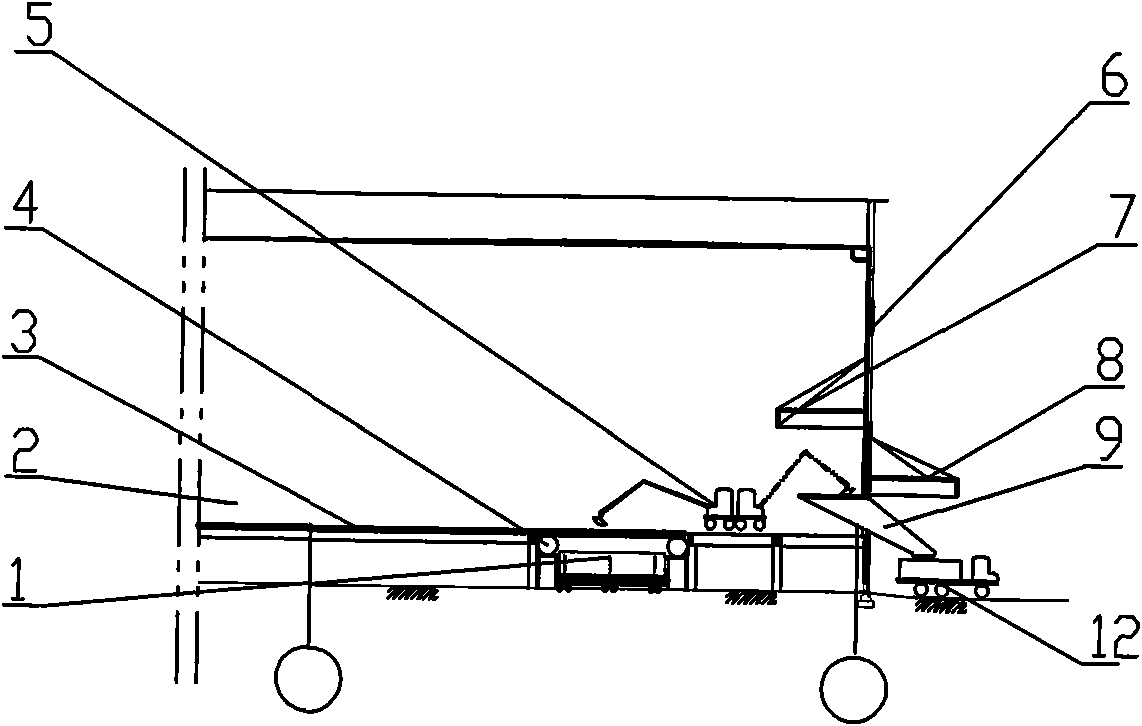

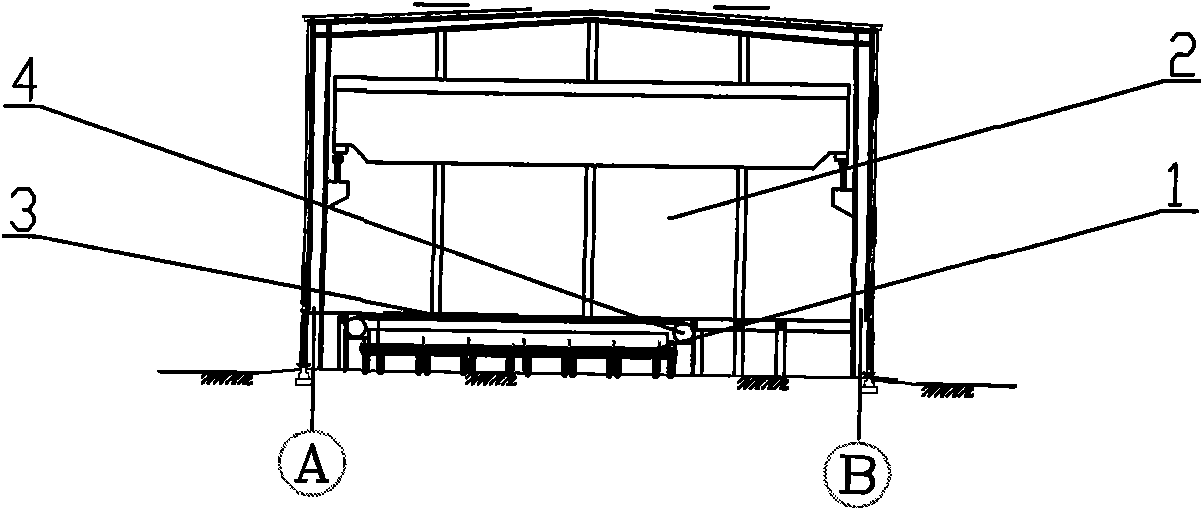

[0019] Such as figure 1 , figure 2 and image 3 As shown, the removal structure of the electrolyzer liner in the centralized overhaul workshop of the electrolyzer of the present invention is as follows: comprising the electrolyzer 1, the planer section 2, the planer section 2 is provided with an operating platform 3, and ventilation is provided outside the electrolyzer overhaul workshop The machine room 11 and the operating plane of the planer furnace section 2 are set on a plane higher than the ground or the electrolytic cell. An operating platform 3 is provided in the planer furnace section 2, and a dust collection pipe 4 is arranged around the upper part of the electrolytic cell 1. The operating platform 3 is provided with dismantling equipment 5, and dust collection devices are respectively provided on the inner side and outer side of the end wall 6 of the overhaul w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com