Perforating explosion-proof gun device

A perforating gun and anti-explosion technology, which is applied in the fields of mining fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of blasting gun accidents, construction well scrapping, high cost of blasting gun accidents, etc., to prevent blasting gun accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

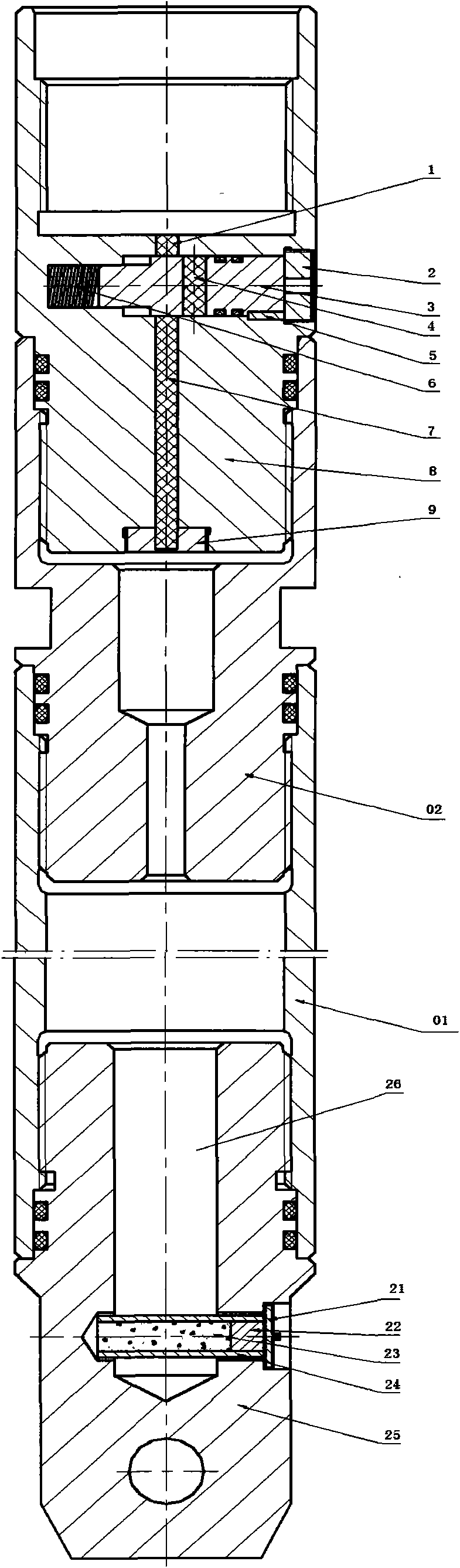

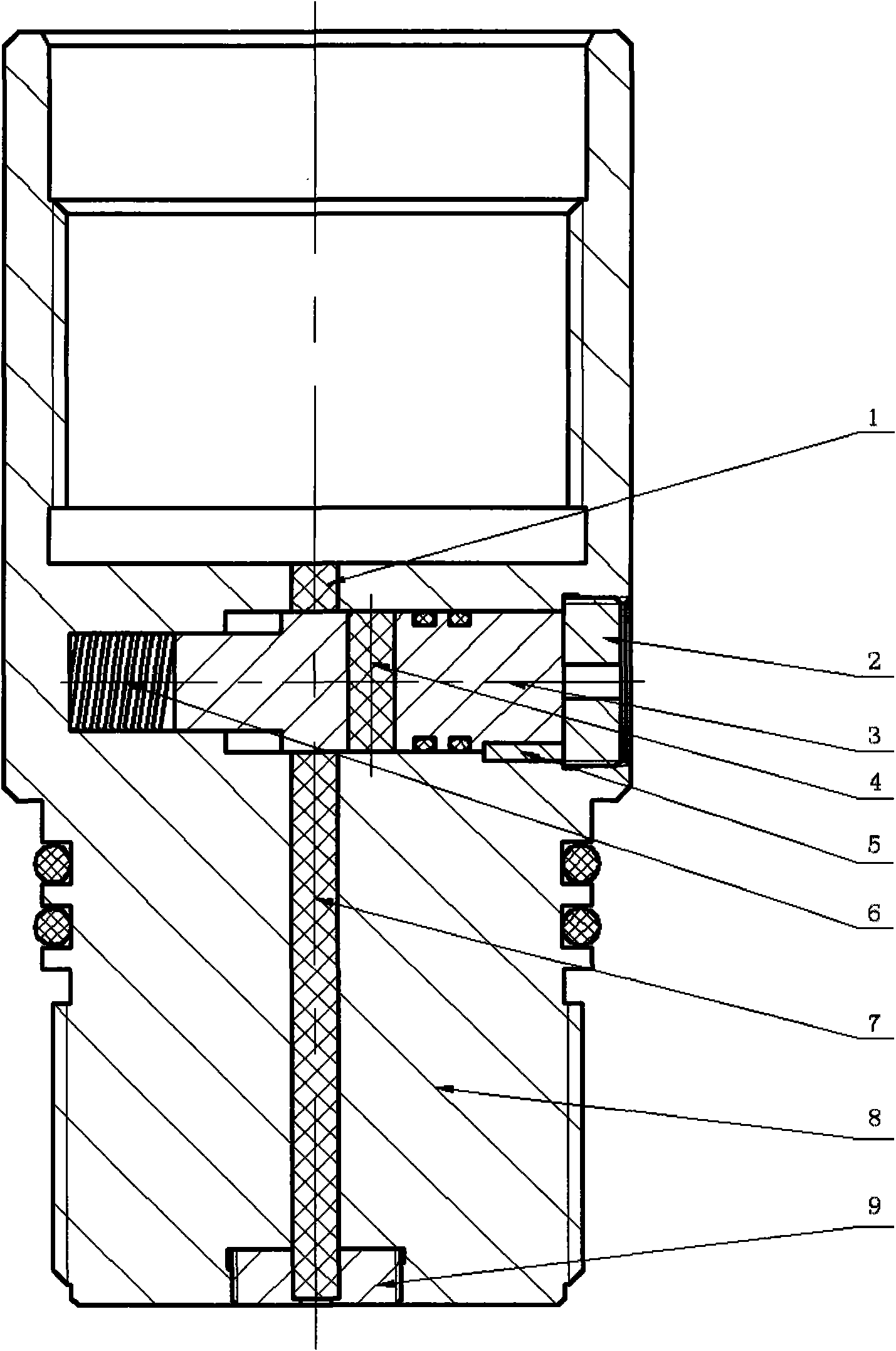

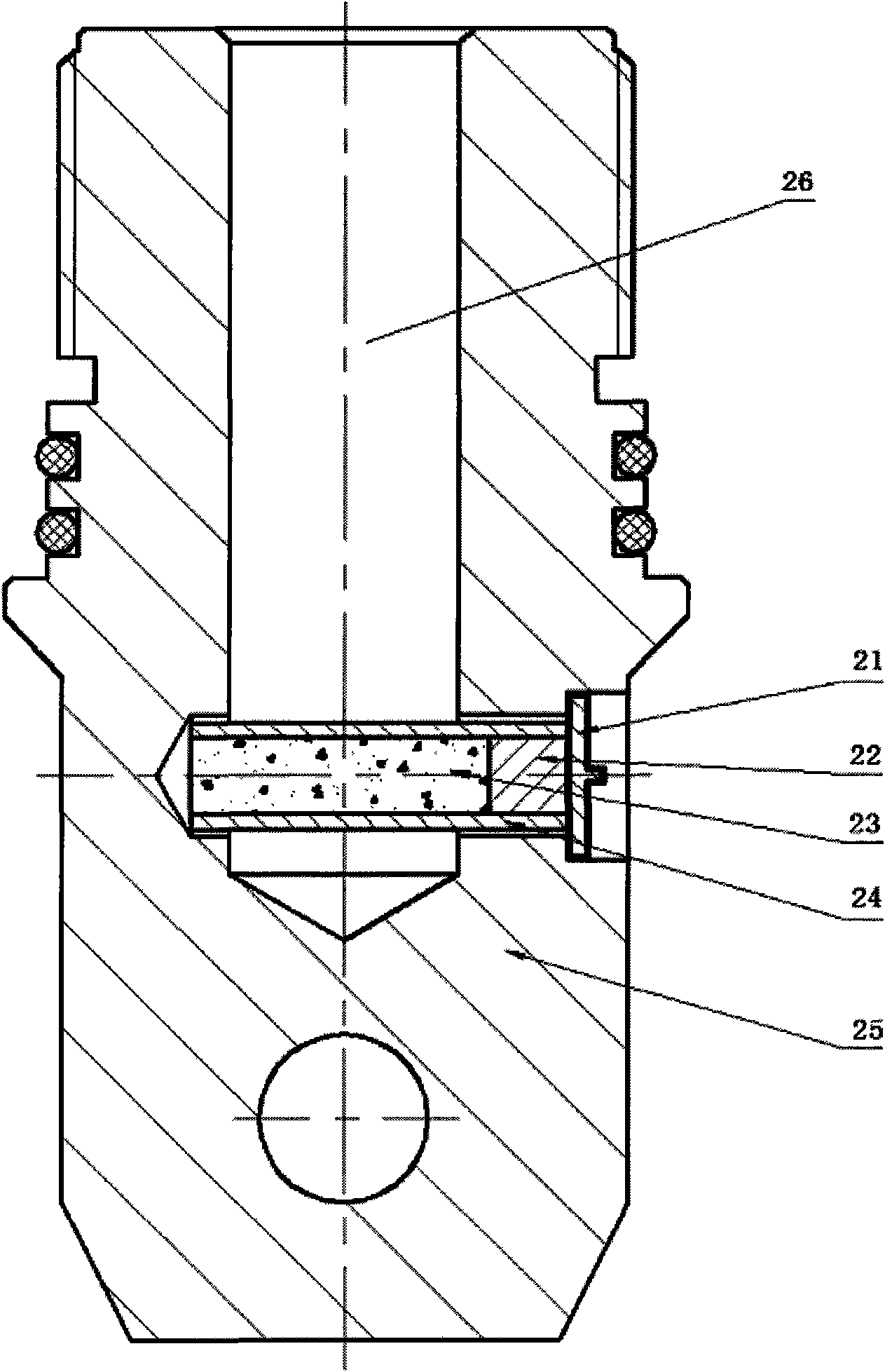

[0018] Referring to the accompanying drawings, the perforating anti-explosion gun device of the present invention includes a perforating gun 01, a detonation mechanism is installed on the gun head 02 of the perforating gun, and a water opening mechanism is installed at the tail end of the perforating gun 01, The two mechanisms are used in conjunction, and the water-contacting mechanism doubles as the tail of the perforating gun;

[0019] Detonation mechanism ( figure 1 , figure 2 ) includes: a first booster charge 1, a piston retaining screw 2, a piston 3, a second booster charge 4, a directional key 5, a spring 6, a third booster charge 7, a breaking joint 8 and a booster charge Column retaining screw 9;

[0020] Wherein, one end of the explosion-breaking joint 8 has an external thread, and the other end has an internal thread, and the center of the explosion-breaking joint 8 has a central hole, and a side hole is radially opened in the explosion-breaking joint 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com