Method and device for bonding magnetic steel of external rotor duplex magnetoelectric machine

A technology for permanent magnet motors and outer rotors, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems that cannot satisfy the spatial position relationship of the magnetic steel of the outer rotor compound permanent magnet motor, affect the production quality of the outer rotor compound permanent magnet motor, and cause the magnetic steel to stick To solve problems such as poor connection accuracy, achieve the effect of convenient operation, reduce labor intensity, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

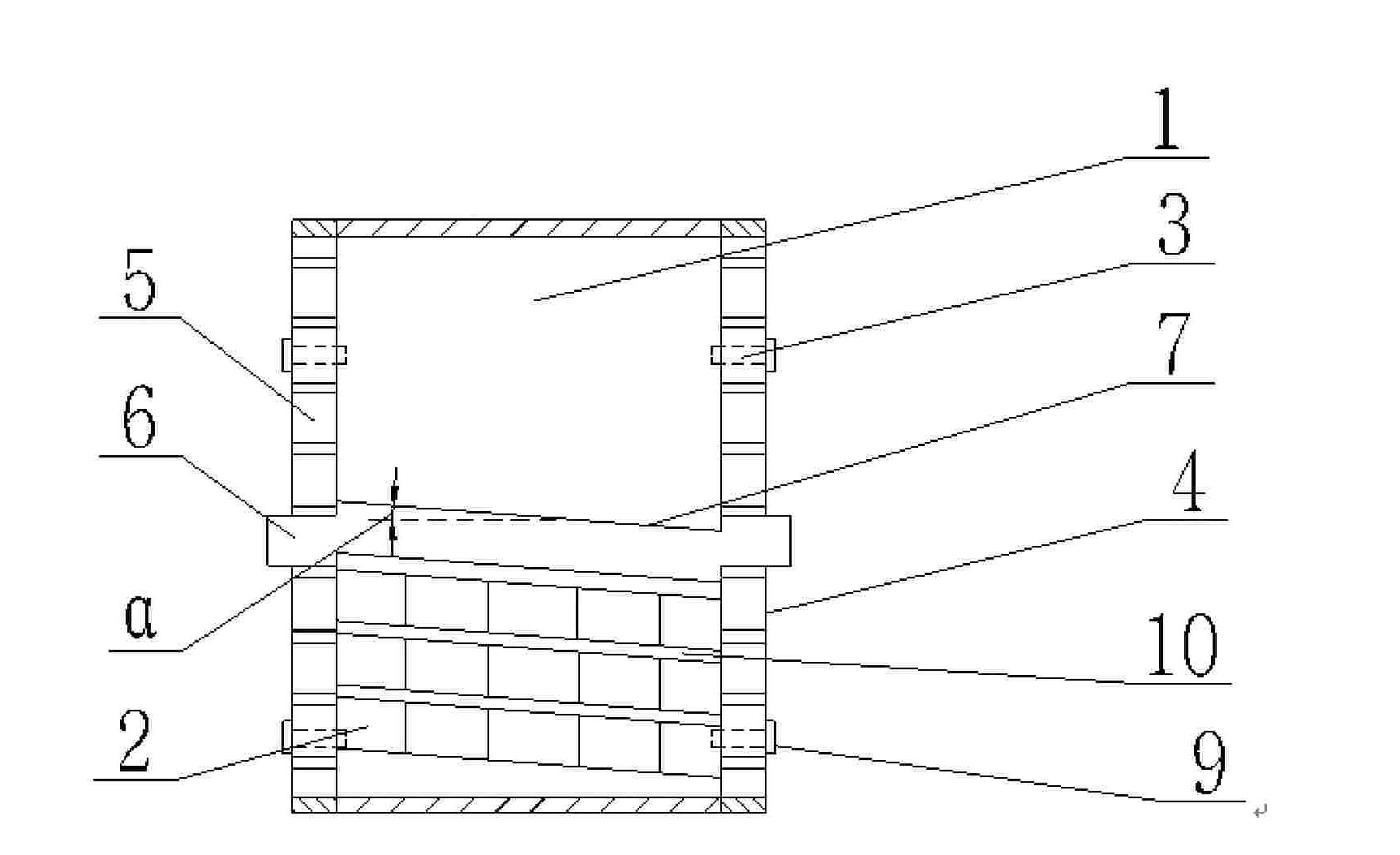

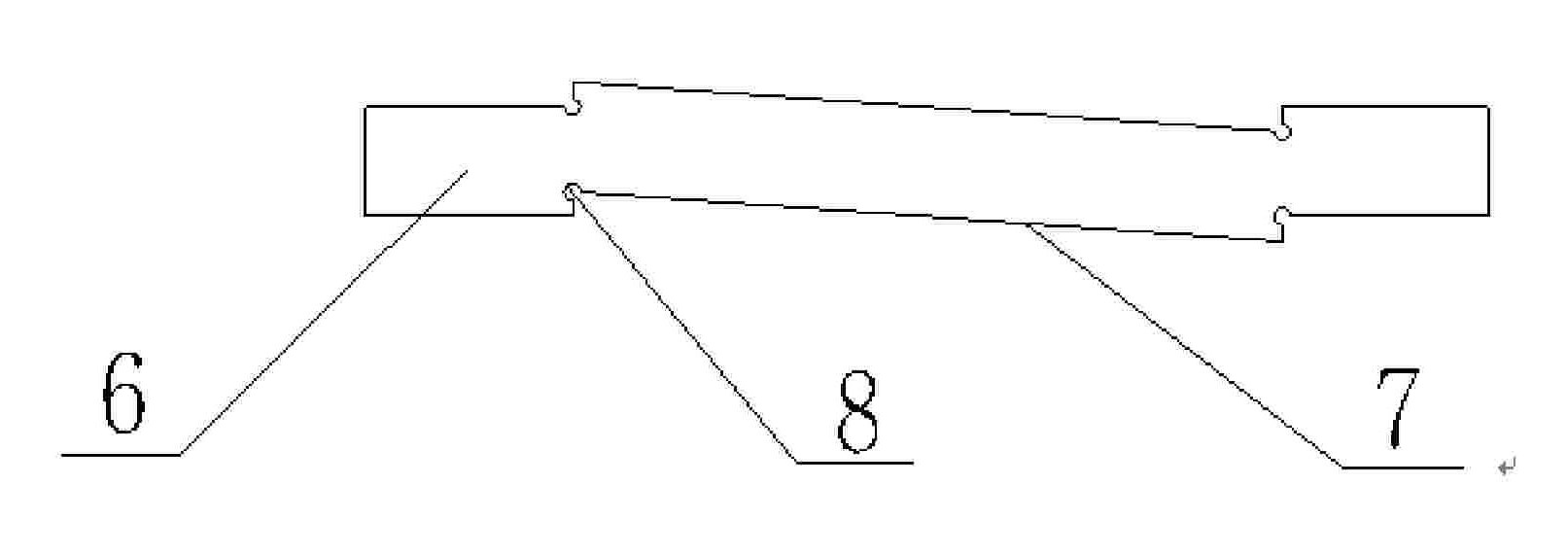

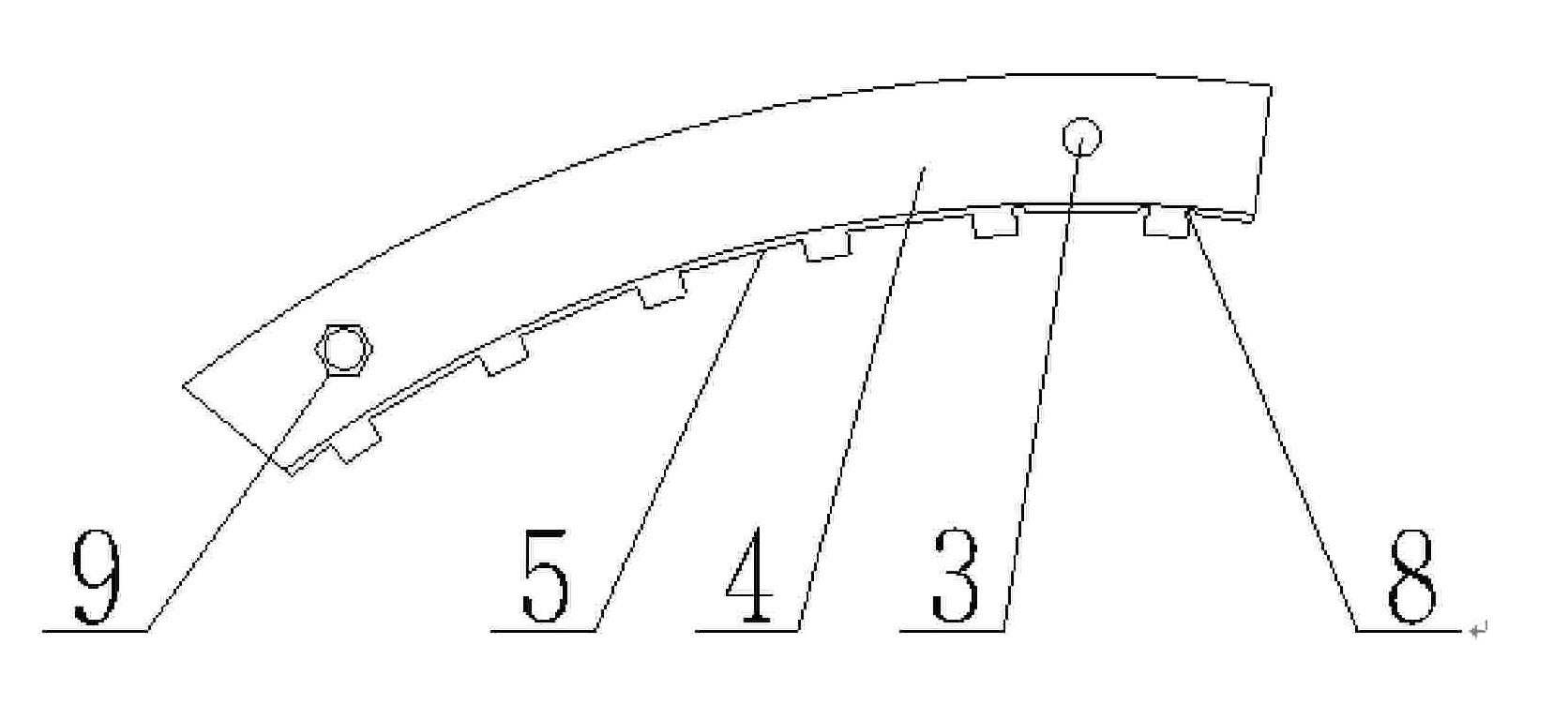

[0015] Embodiment of the present invention: when pasting the block magnetic steel 2 on the inner circle of the cylindrical shell 1 of the outer rotor compound permanent magnet motor, two or more uniform magnets are made on the two end faces of the shell 1 respectively. Distributed positioning holes 3, and make the positioning holes 3 on the two end faces of the shell 1 correspond to the same axis one by one, and then make two identical arc-shaped clamping plates 4, and the inner arc of the arc-shaped clamping plate 4 Make the same number of positioning slots 5 at the same position on the side, and make two positioning holes with the same position as the positioning hole 3 on the end face of the shell 1 on each arc clamping plate 4, and place the arc clamping plate Fix a positioning plate 6 in each positioning groove 5 on the inner arc edge of the arc-shaped clamping plate 4, and make each positioning Both ends of the plate 6 are stuck in the positioning groove 5 on the same ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com