Adhesive assembly method of reflector and support

A mirror support and assembly method technology, applied in the field of mirrors, can solve the problems of unguaranteed bonding reliability and low bonding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

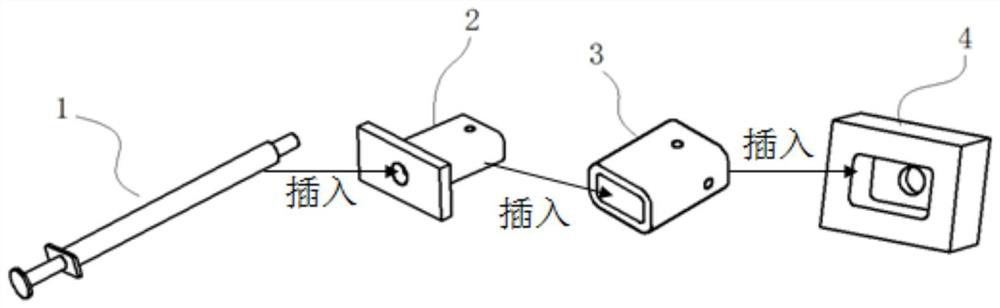

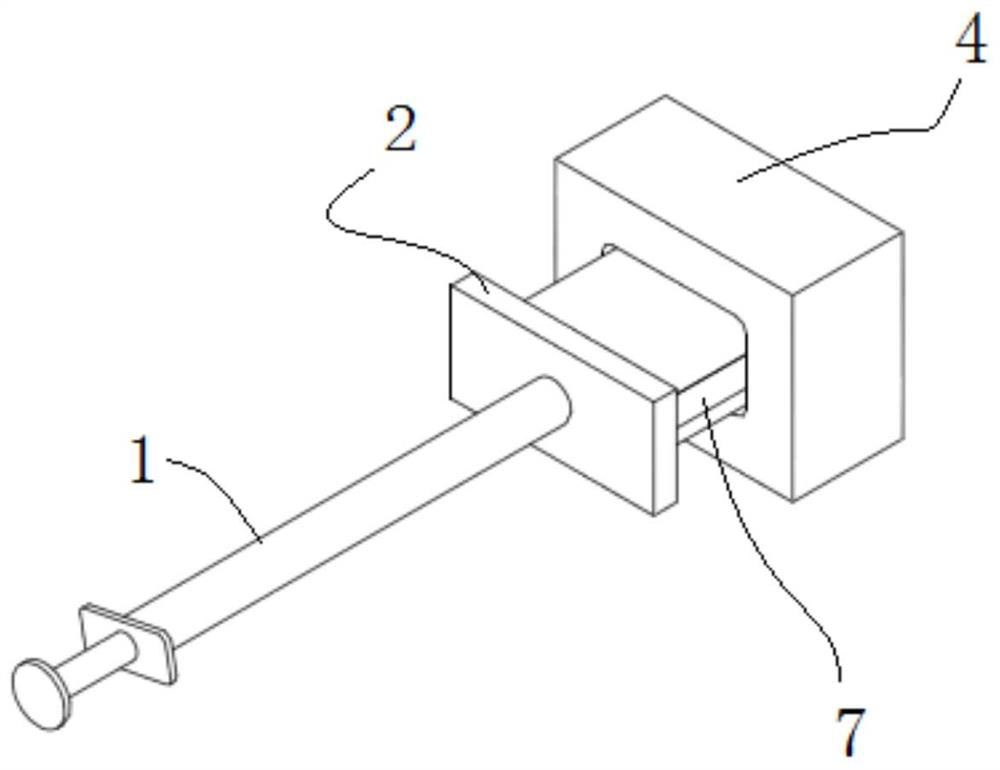

[0096] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

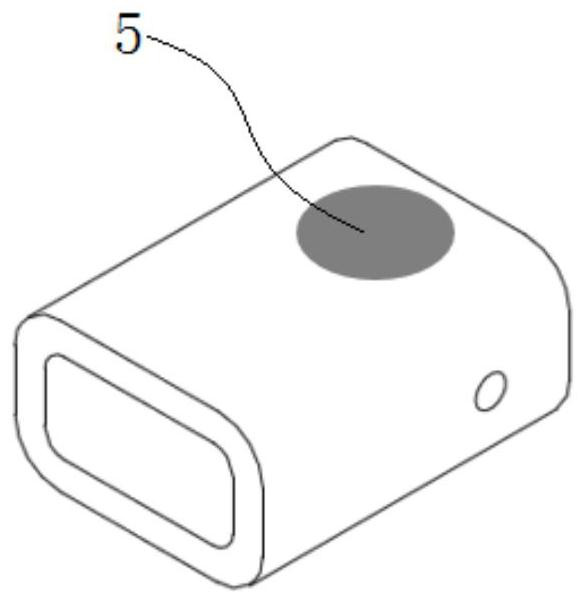

[0097] For the convenience of subsequent understanding, first, the structure of the reflector and support to be glued and assembled in this embodiment is described as follows in conjunction with the accompanying drawings:

[0098] The diameter of the reflector is between 100mm and 400mm; Figure 12 As shown, the reflector includes a mirror surface 17 and a reflector back 16 , and three first rectangular holes 15 are provided on the side wall of the reflector back 16 .

[0099] Such as Figure 14 As shown, one of the end surfaces of the support is provided with a boss 19, and the four sides of the boss 19 are provided with first glue injection holes 20; the shape of the boss 19 is adapted to the first rectangular hole 15 on the reflector , can be inserted into the first rectangular hole 15, the boss 19 and the first rectangular hole 15 are cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com