Preparation method of vibration cavity of plate ceramic frequency device and special platform for adhering it

A technology of frequency devices and vibrating chambers, which is applied in the field of patch workbenches, can solve the problems of restricting product production and development, affecting product performance and pass rate, etc., and achieves the effects of low cost, simple complex process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

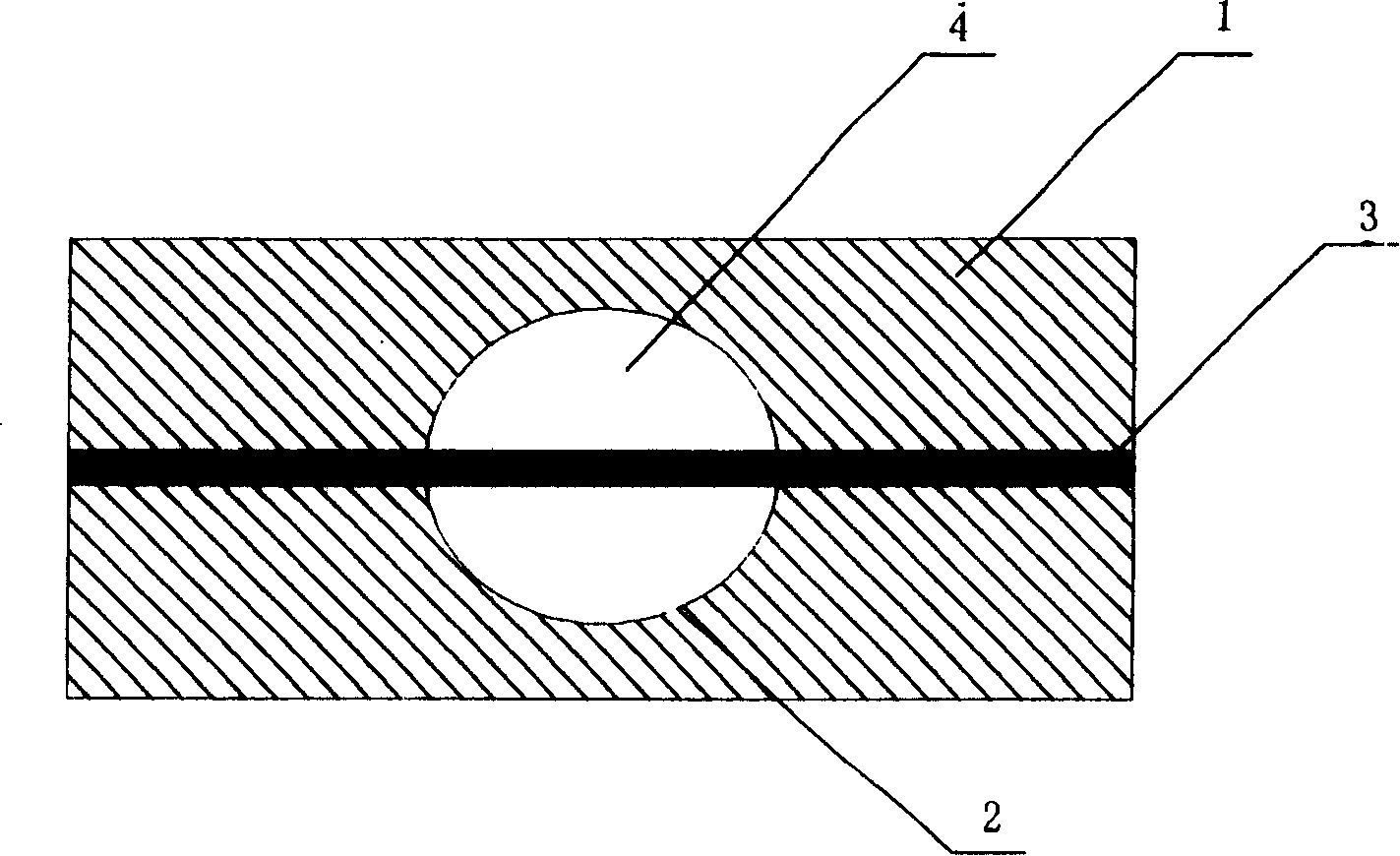

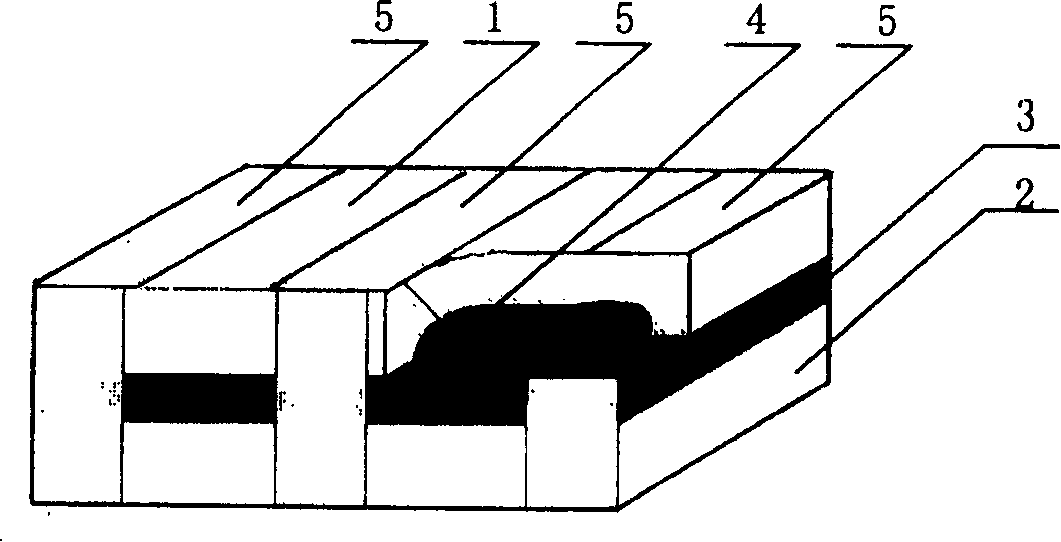

[0025] As shown in the drawings, the piezoelectric vibration cavity is composed of an upper ceramic plate 1 , a lower ceramic plate 2 , a piezoelectric vibrator 3 and a cavity 4 . The preparation processes of the upper ceramic plate 1 and the lower ceramic plate 2 are basically the same, the difference is that the upper ceramic plate 1 has tin electrodes 5 made by printing.

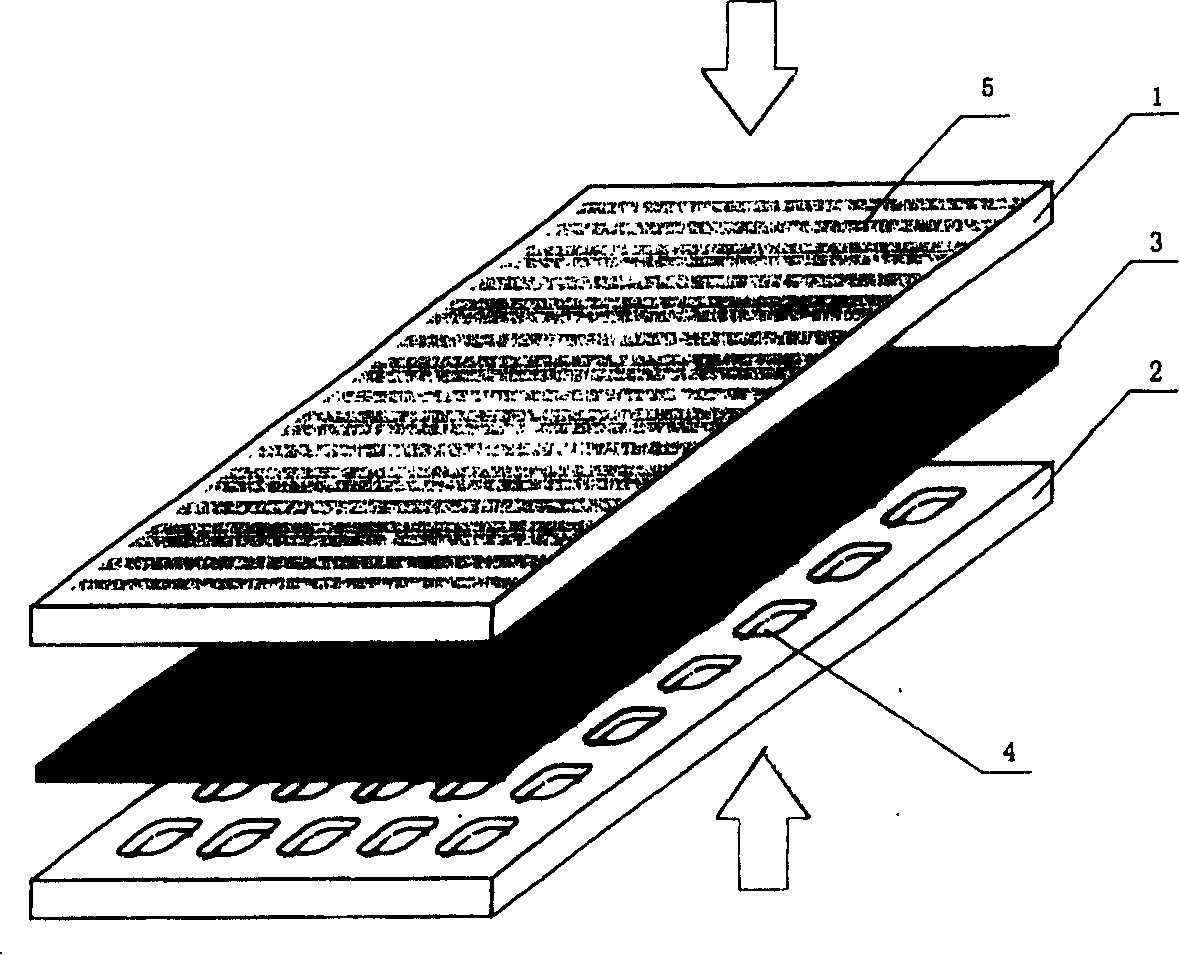

[0026] The sticky sheet workbench used is by a platform 6, and there is a protruding small platform 8 with many apertures 7 in the middle of the platform, and the protrusion of the small platform is to take and put for convenience of sticky paper and ceramic sheet. There are three positioning pins 9 on the two mutually perpendicular sides of the small platform, two of which are close to the long side, and one is close to the short side. There is an air extraction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com