Load ring mounting of pumping plunger

A grommet and plunger technology, which is applied to the components of pumping devices for elastic fluids, fuel injection devices, charging systems, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

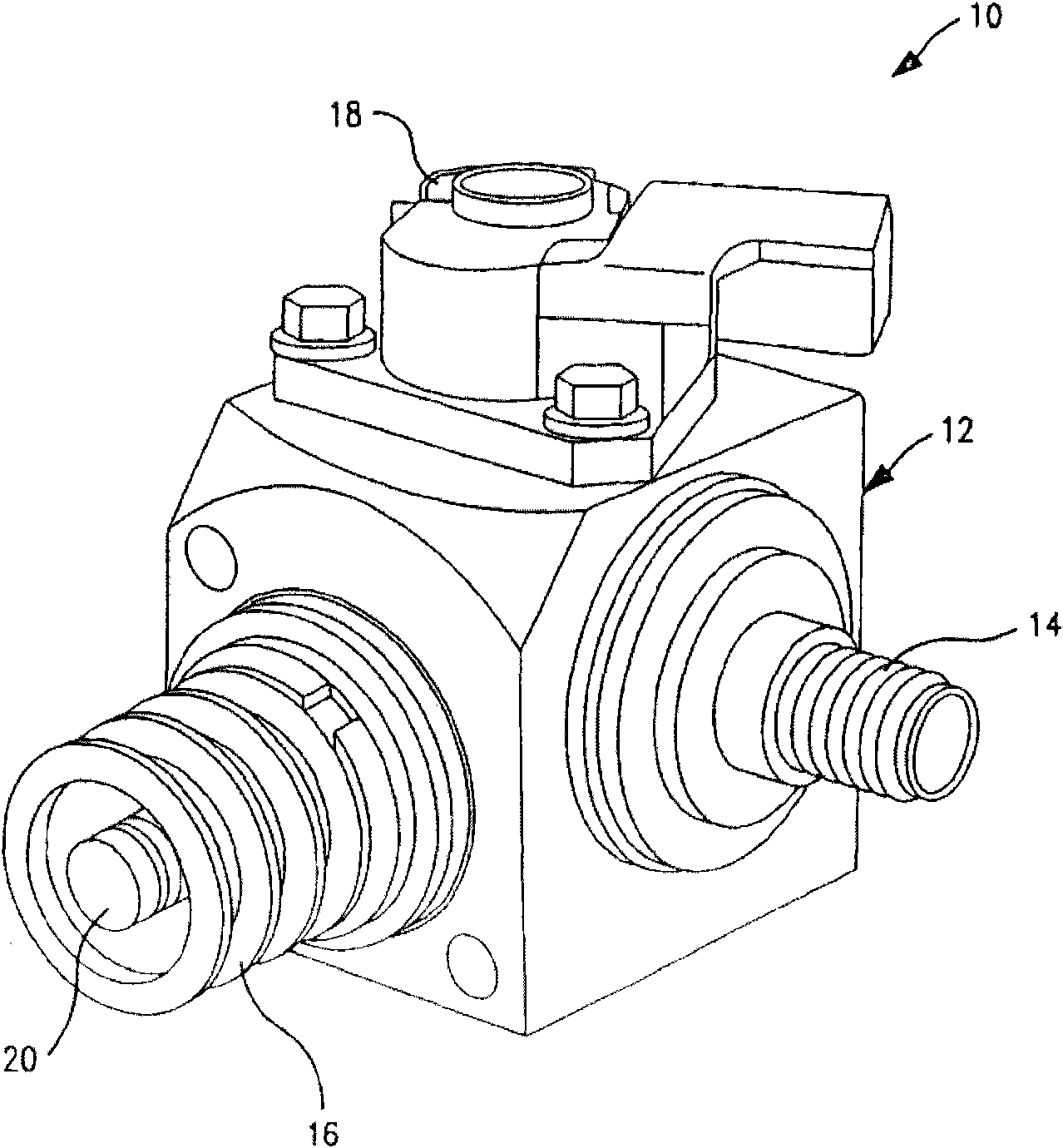

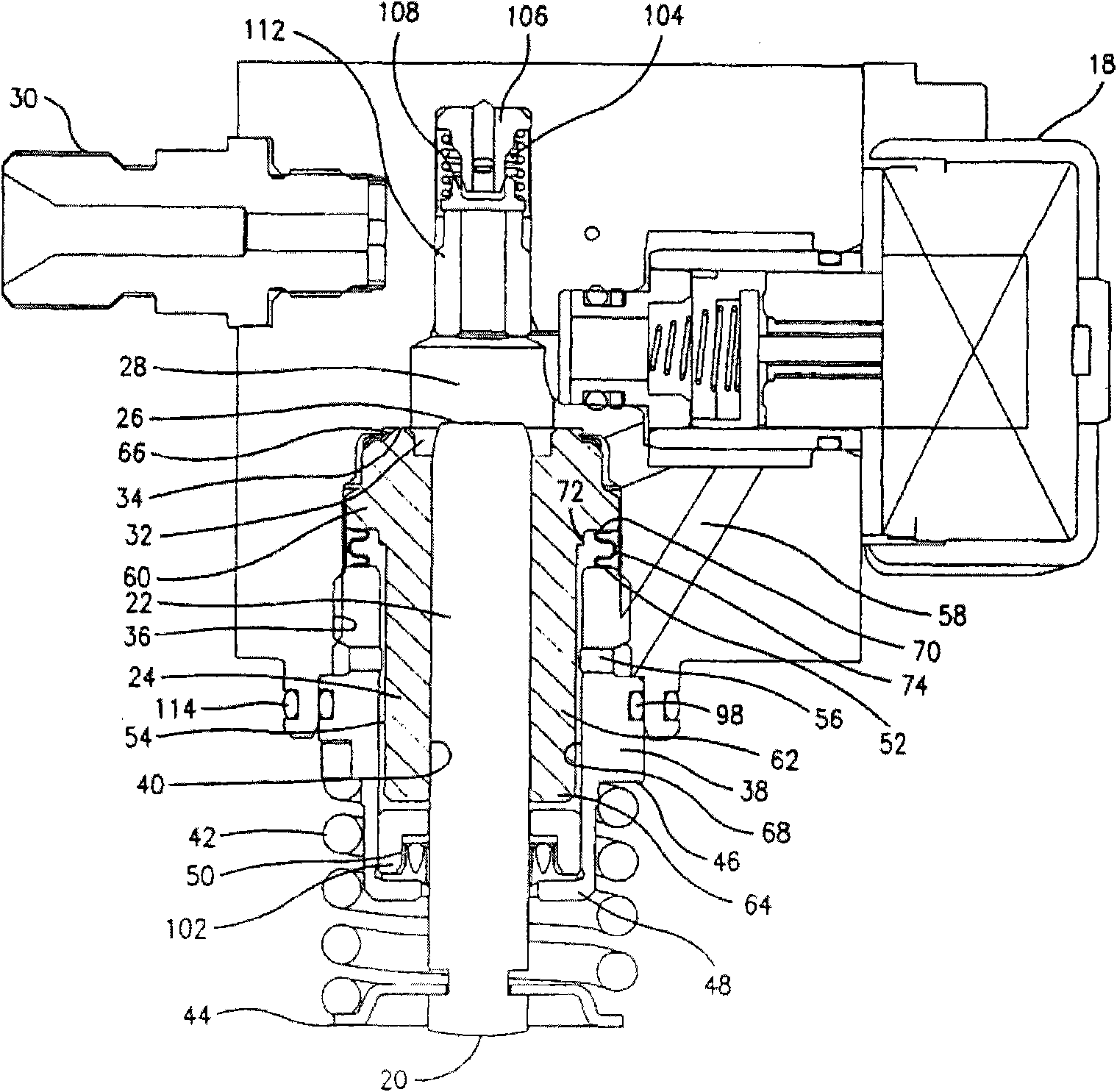

[0016] figure 1 A single plunger fuel pump 10 is shown having a generally cuboidal housing or body 12 with a fuel feed fitting 14 protruding from the right, a single plunger drive assembly 16 protruding from the left, and a Protruding feed control valve 18.

[0017] now refer to figure 1 and figure 2 , it will be readily understood that the engine drive shaft is provided with lug-type cams (not shown) which cause the distal end 20 of the pumping plunger 22 to internally charge the pumping sleeve 24 fixed to the housing ( Feeding) and unloading (discharging) stage reciprocating motion. The other pumping end 26 of the plunger is located in a pump chamber 28, which is filled with fuel at a feed pressure of about 4 bar during the charging phase, and is preferably subject to initial overflow control, pressurizing the fuel in the pump chamber to Approximately 200 bar to be delivered via discharge connection 30 to eg a common rail (not shown). Fuel is supplied directly to the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap