Volume meter for flowing media with selective coupling between counter system and calculating unit

A technology for calculating units and flowing media, applied in the field of volume meters, can solve problems such as inability to distinguish between different media, errors in determining consumption, etc., to achieve the effect of improving effectiveness and/or accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

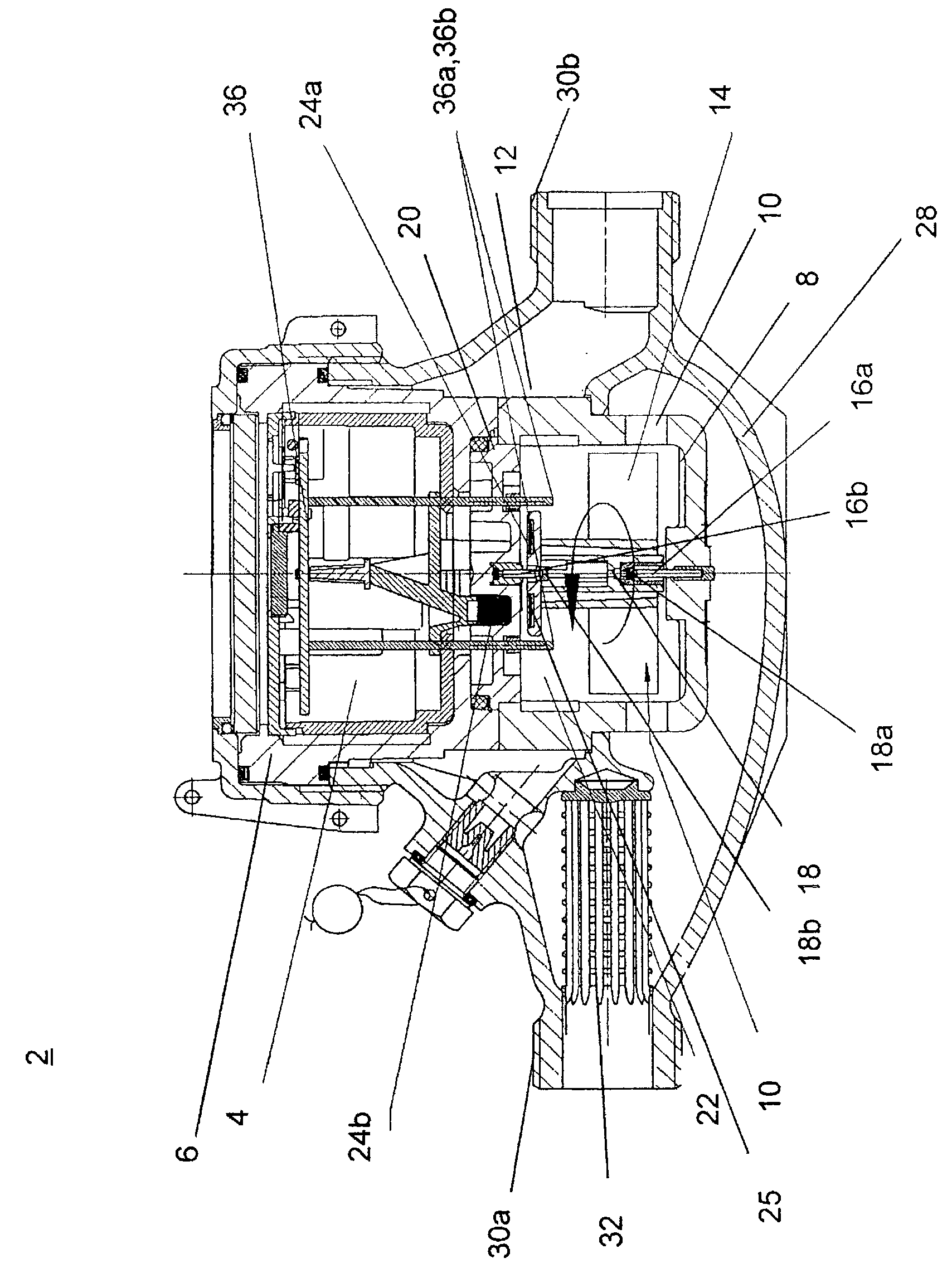

[0035] exist figure 1 Among them, the multi-jet impeller water meter 2 designed according to the example of the present invention is shown in cross-sectional view. This capacity meter 2 has: an electronic calculation unit 4, which is arranged in a calculation unit housing 6 designed in the form of a bucket; Body 8 , which has an inflow line 10 and an outflow line 12 , in which a measuring body designed as an impeller 14 is rotatably arranged. The measuring application housing 8 of bucket-shaped design has a bucket-shaped bottom, wherein the first end 18 a of the impeller shaft 18 which receives the impeller 14 is rotatably arranged in the first support 16 a. Furthermore, the first support plate 20 has a second support 16b in which the second end 18b of the impeller shaft 18 is rotatably arranged and which upwardly delimits the measurement use housing 8 and together with the measurement The original measuring chamber 22 is enclosed by the housing 8 .

[0036]The housing 8 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com