Disc brake for hinge sliding type vehicle

A brake and sliding technology, applied in the direction of brakes, vehicle parts, brake components, etc., can solve the problems of cost increase, weight increase, and number of parts, etc., to achieve low cost, low miniaturization, and reduce the number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

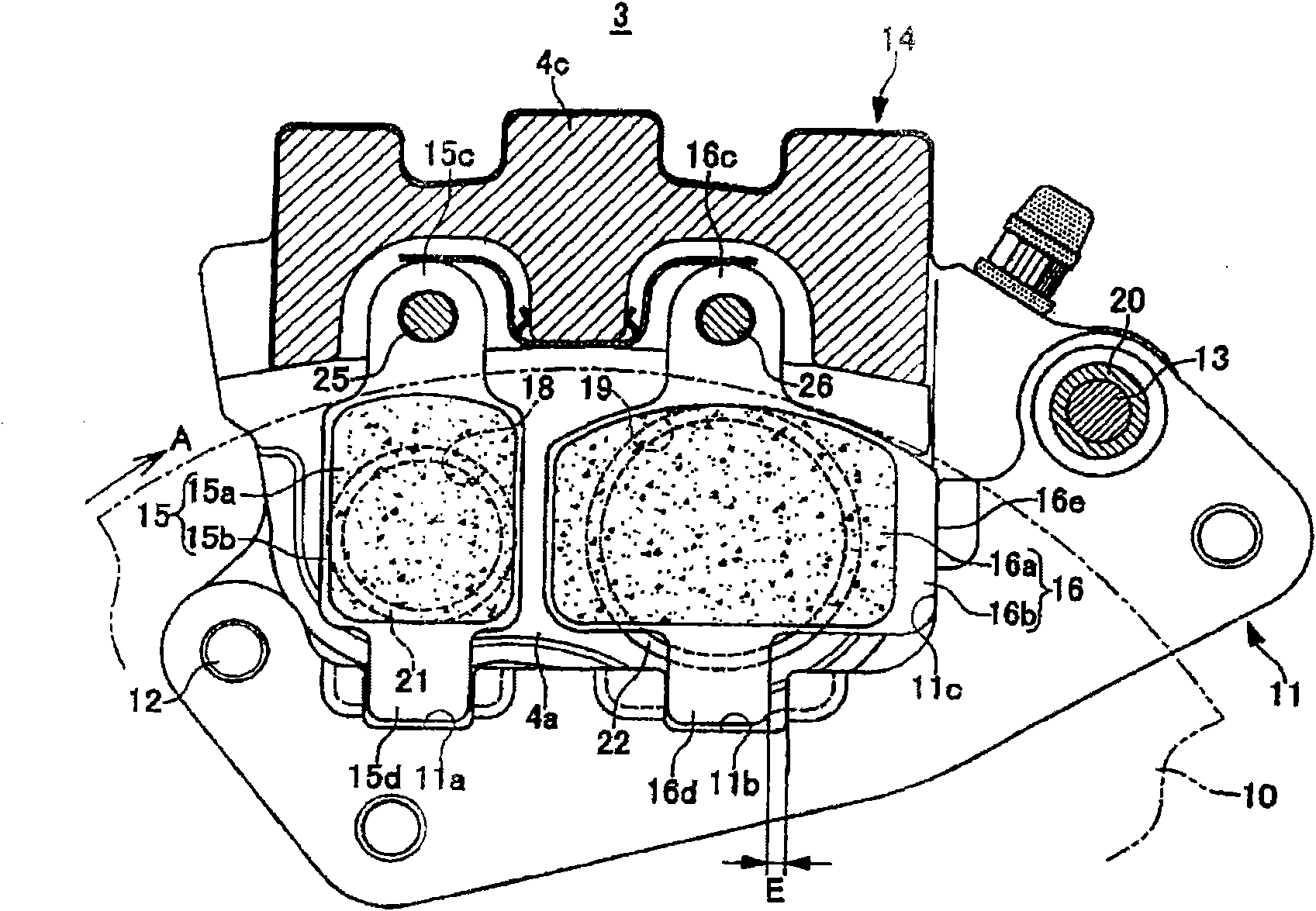

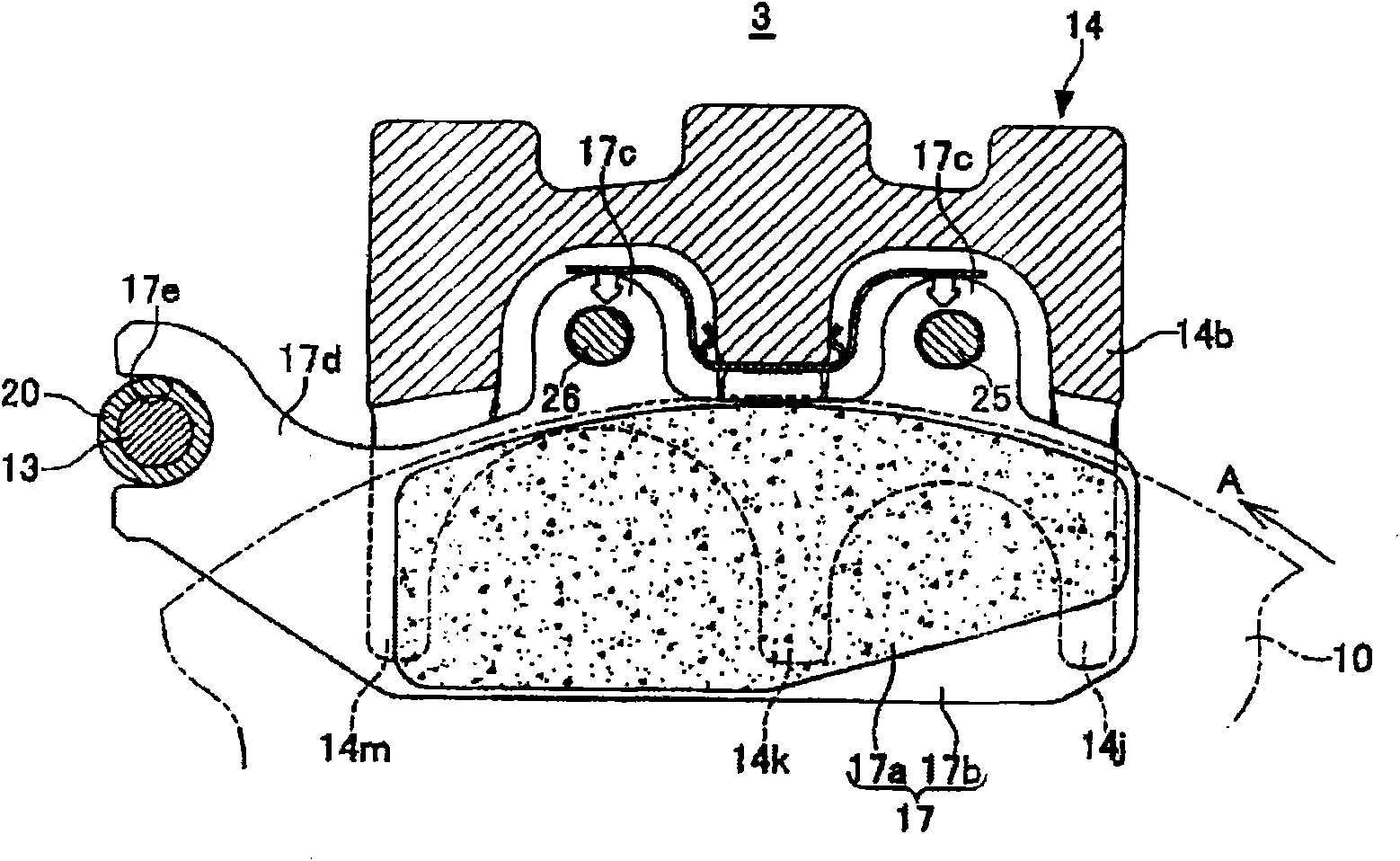

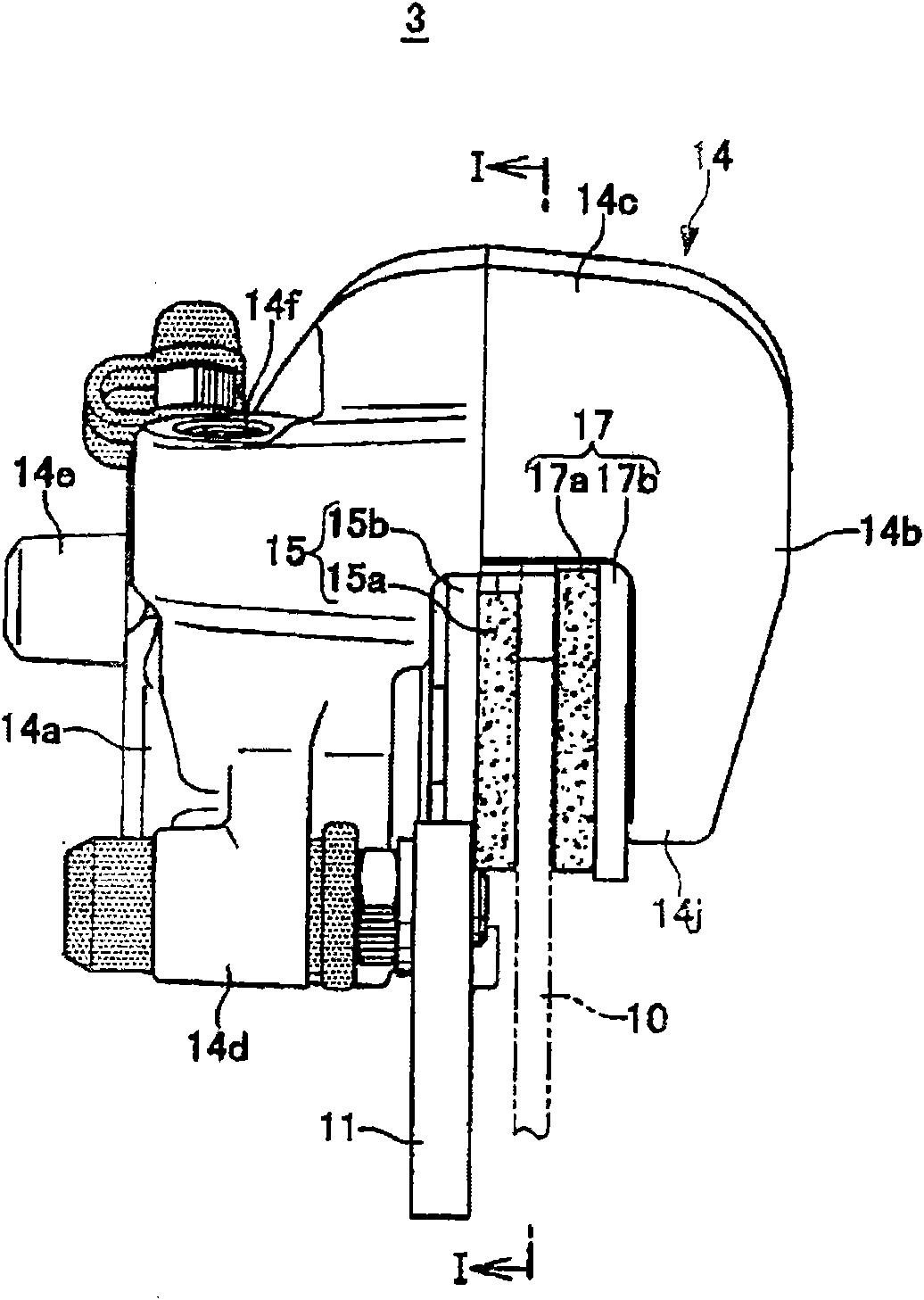

[0046] Figure 1 to Figure 8 It is a figure showing an embodiment of the hinge slide type vehicle disc brake of the present invention, figure 1 yes image 3 I-I sectional view, figure 2 yes Figure 4 II-II sectional view, image 3 is the side view of the disc brake, Figure 4 is the top view of the disc brake, Figure 5 yes Figure 4 The V-V sectional view, Image 6 yes Figure 8 The VI-VI sectional view, Figure 7 yes Figure 8 Sectional view of VII-VII, Figure 8 It is a system diagram of a disc brake device to which the disc brake of the present invention is applied. Arrow A in the figure indicates the rotation direction of the disc rotating body when the vehicle is running forward, and the disc turning-in side and the disc turning-out side used in the following description refer to the situation when the vehicle is moving forward.

[0047] Such as Figure 8 As shown, the lever-type handlebar brake device 1 of this embodiment has: an independent system brake sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com