Three-section cover of operation table

A technology for an operating bed and an upper cover is applied in the field of the structure of the three-section cover of the operating bed, which can solve the problems of easy scratching or falling off, large external dimensions of the three-section cover, and high precision requirements, and achieves that it is not easy to scratch and the external size is reduced. , the effect of low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

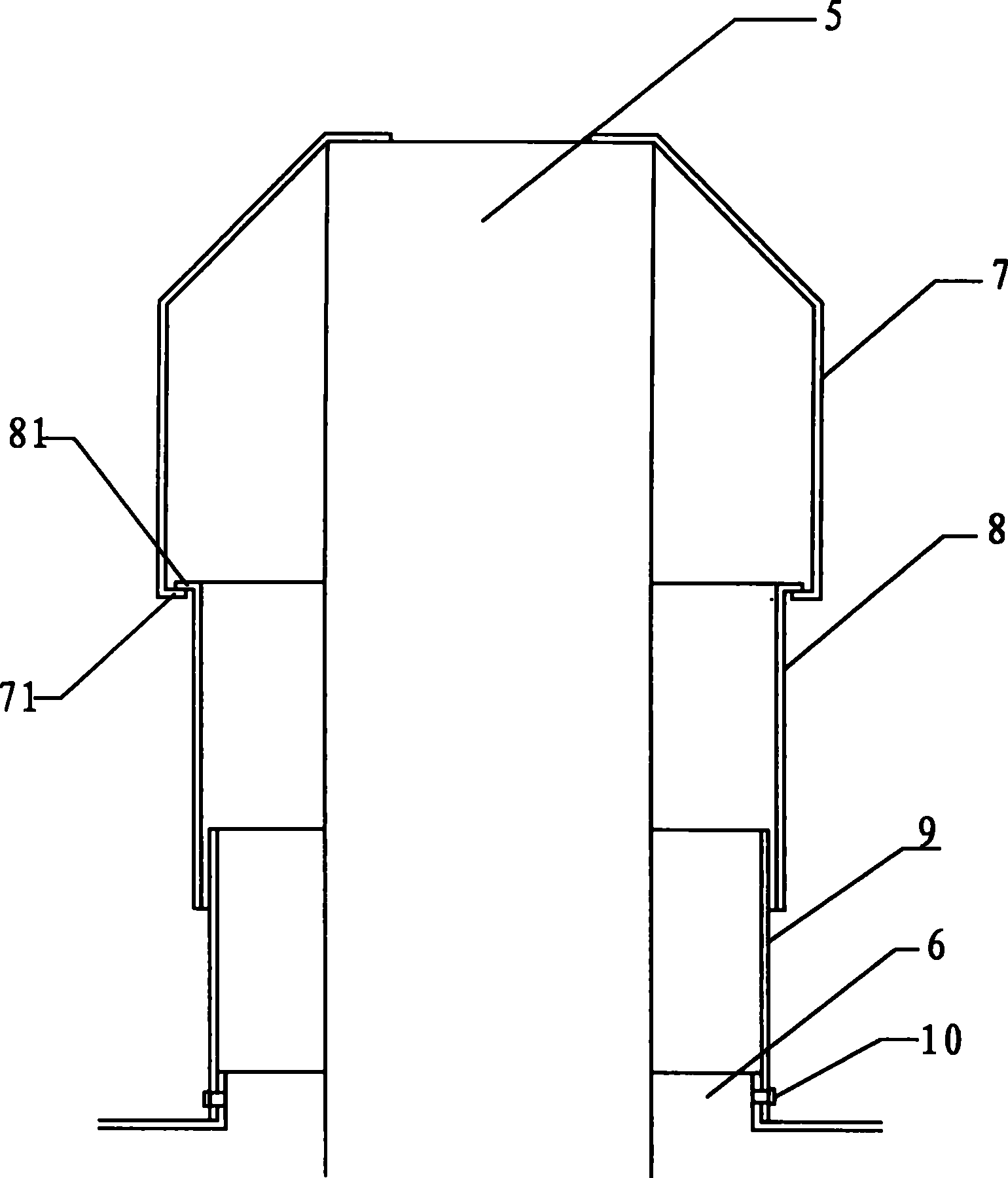

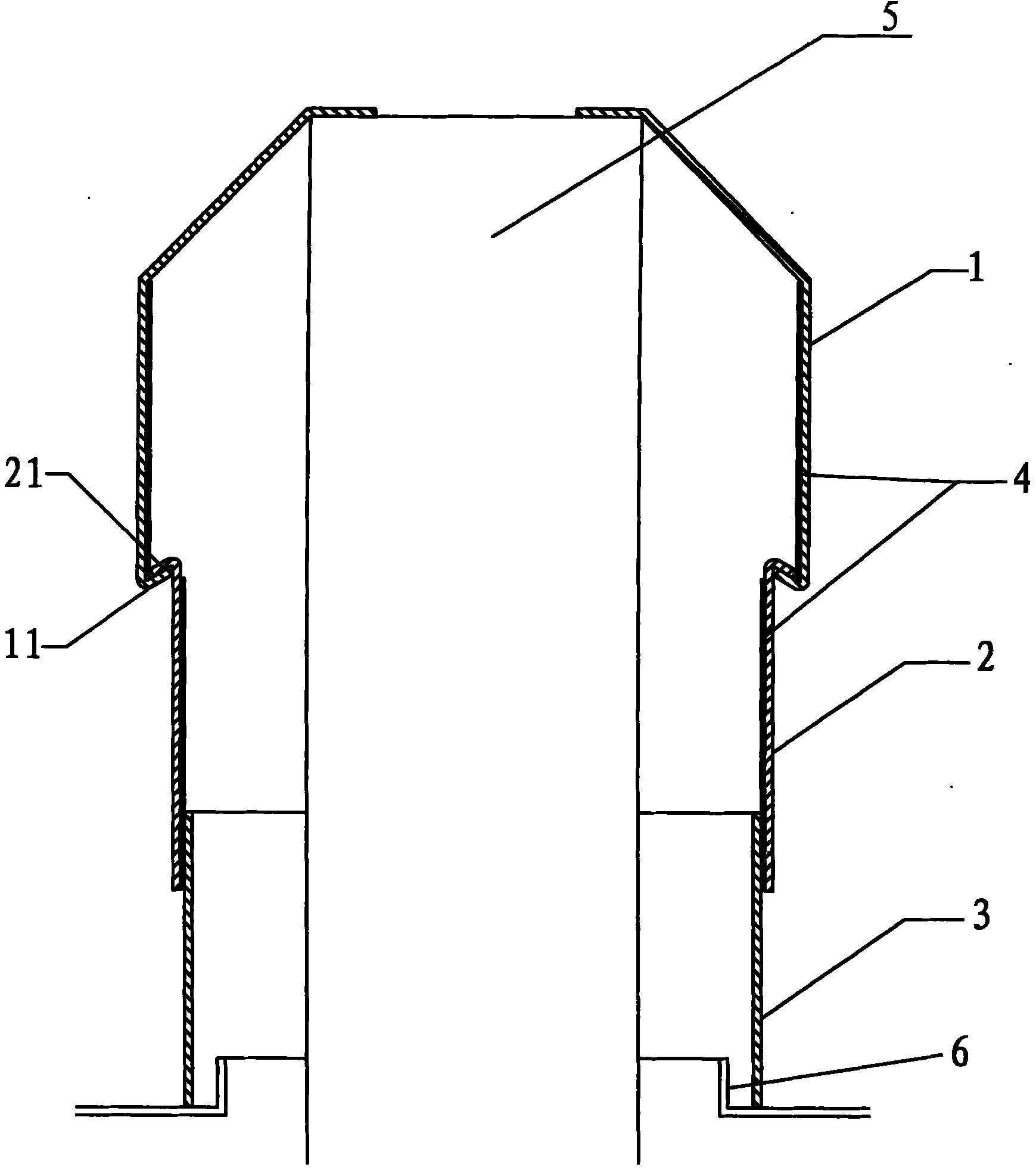

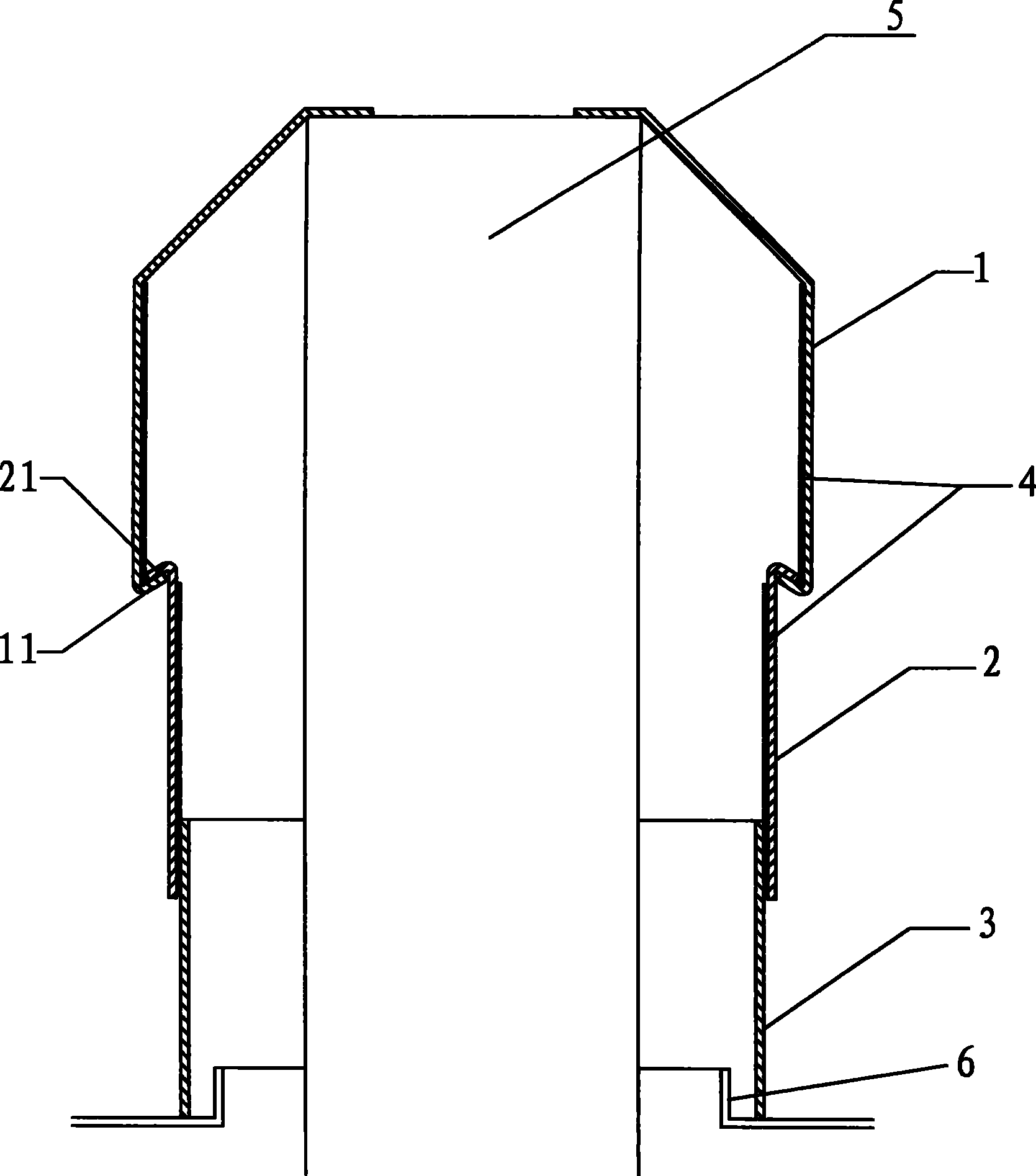

[0012] See figure 2 As shown, the present invention includes an upper cover 1, a middle cover 2 and a lower cover 3, the upper end of the upper cover 1 is fixed on the upper end surface of the lifting system 5, and the lower edge 11 of the upper cover 1 is turned inwardly to form an acute angle; The upper edge 21 turns outwards into an acute angle, and hooks up with the lower edge 11 of the upper cover 1; the upper end of the lower cover 3 is located in the middle cover, and the lower end is not fixed with the base 6, but is free to move.

[0013] It can be seen from the structure of the present invention that the three-section cover of the present invention adopts single reference positioning, only the upper cover 1 is fixed on the upper end surface of the lifting system, and other covers follow the positioning of the upper cover, even if the error between the lifting system and the base is small Large, the three-section cover can also be self-aligning, so the accuracy requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com