Ball bearing

A ball bearing and inner ring technology, applied in the field of bearings, can solve the problems of ball bearing sealing ring performance failure, affecting the service life of the ball bearing, and ingress, so as to enhance the sealing performance and avoid the effect of entering the interior of the ball bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

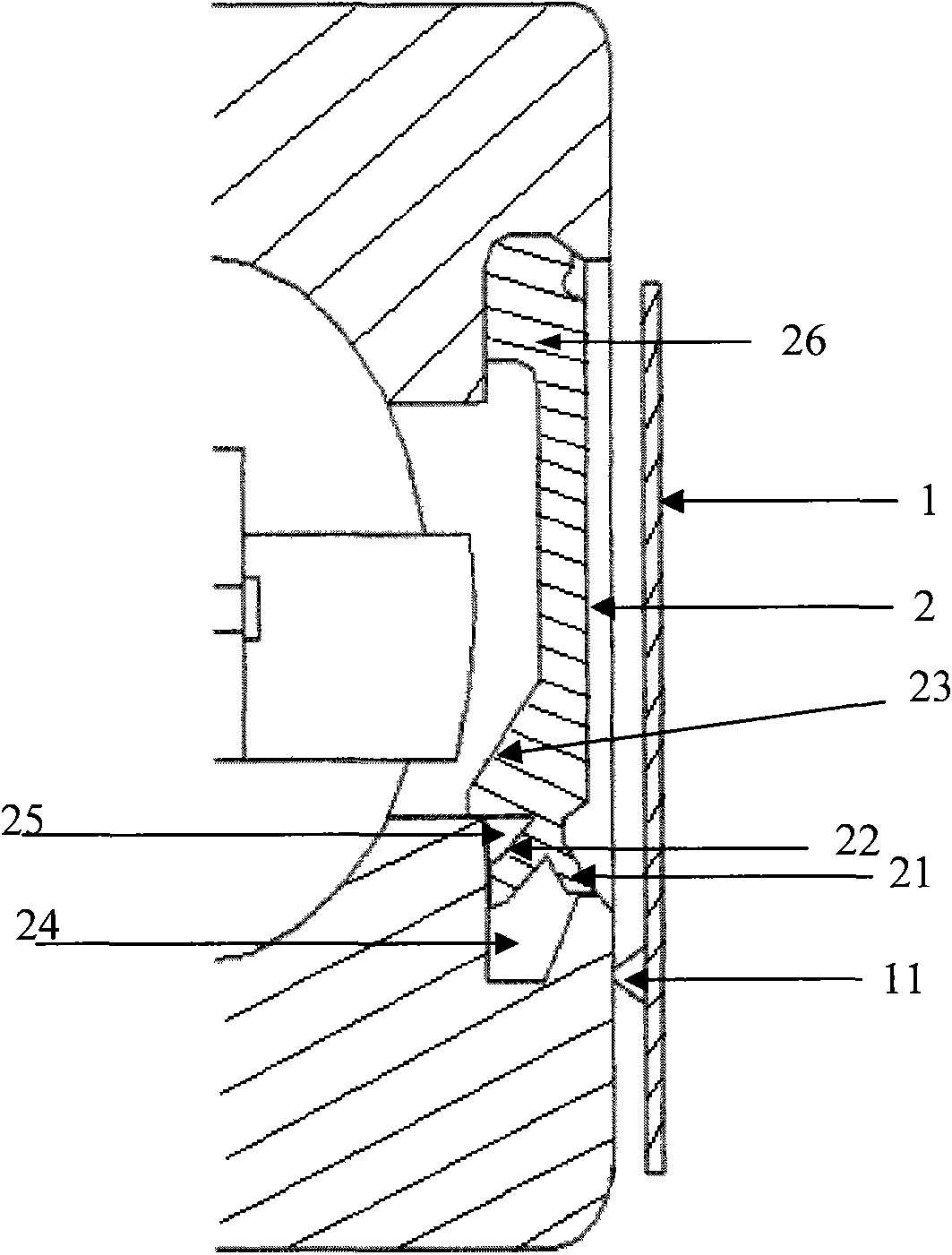

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0027] Under high temperature conditions in industrial applications, the grease inside the ball bearing becomes liquid. At this time, when the ball bearing is running at high speed, the liquid grease may flow out through the sealing lip when the pressure is balanced, which not only causes the inside of the ball bearing The lubrication of the ball bearing is insufficient, and it will contaminate other parts; at the same time, due to the high-speed operation of the ball bearing, the sealing of the ball bearing is damaged, and the grease outside the ball bearing can easily penetrate into the ball bearing. What is more, the external dust enters Inside the ball bearing, causing damage to the ball bearing.

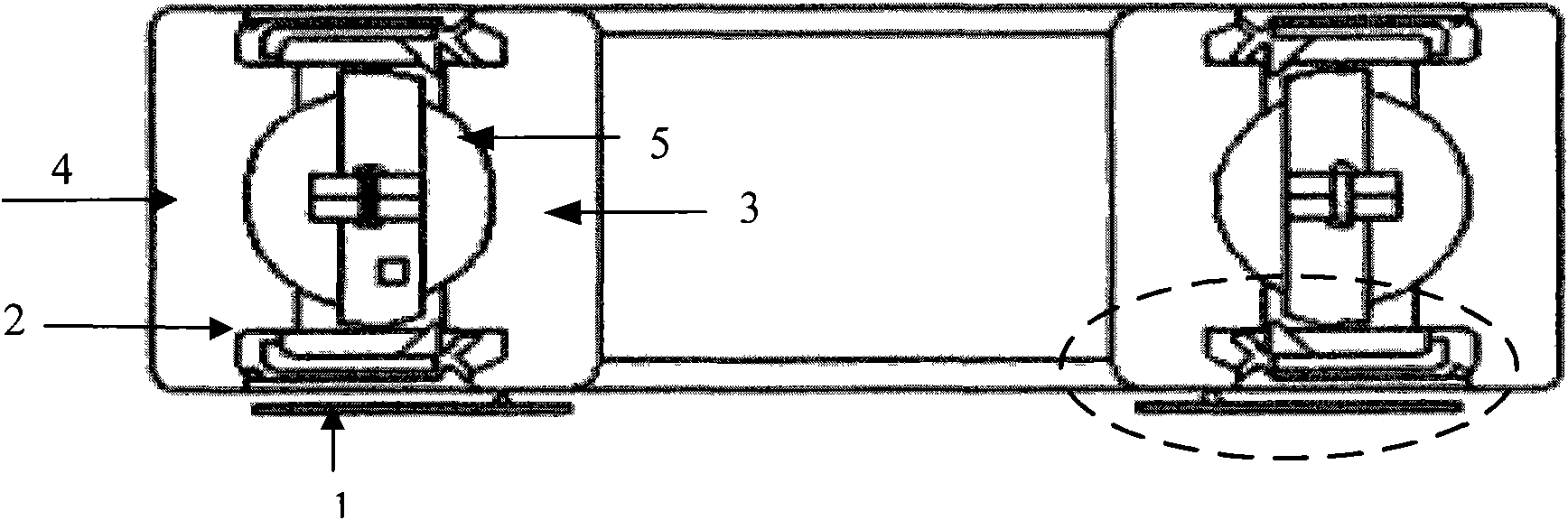

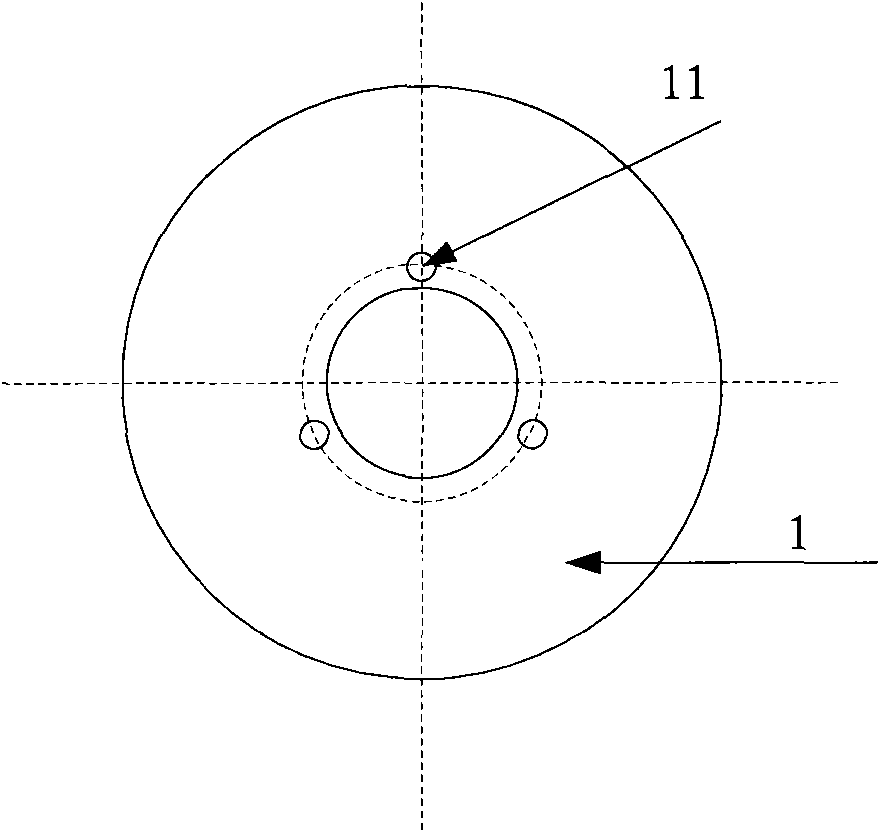

[0028] reference figure 1 , Shows a schematic structural view of an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap