Backlight module and optic plate thereof

A backlight module and optical board technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as light loss, reduce light utilization, increase the number of light interfaces, etc., to improve light uniformity and light utilization The effect of avoiding the afterimage of the light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The optical plate of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

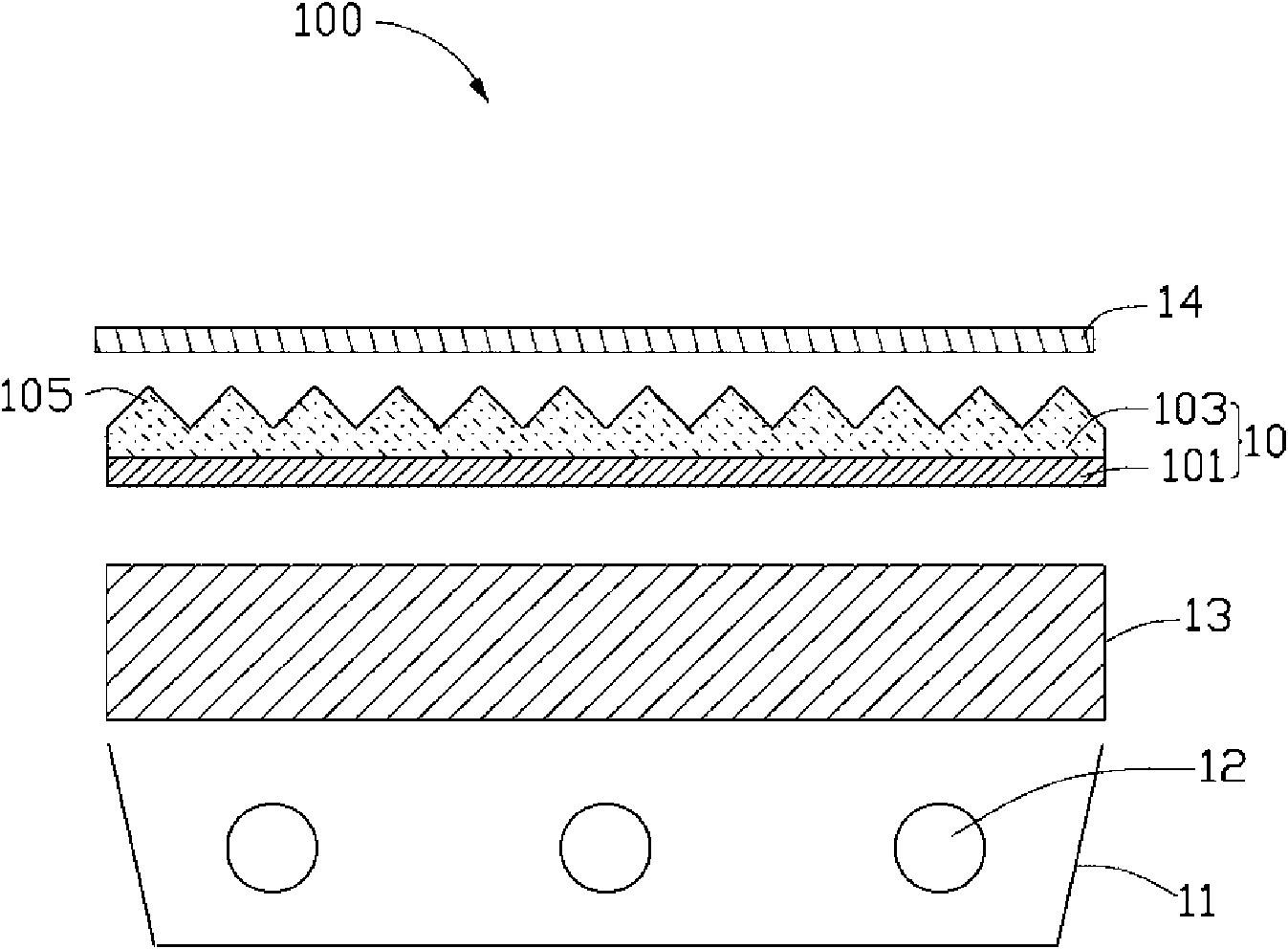

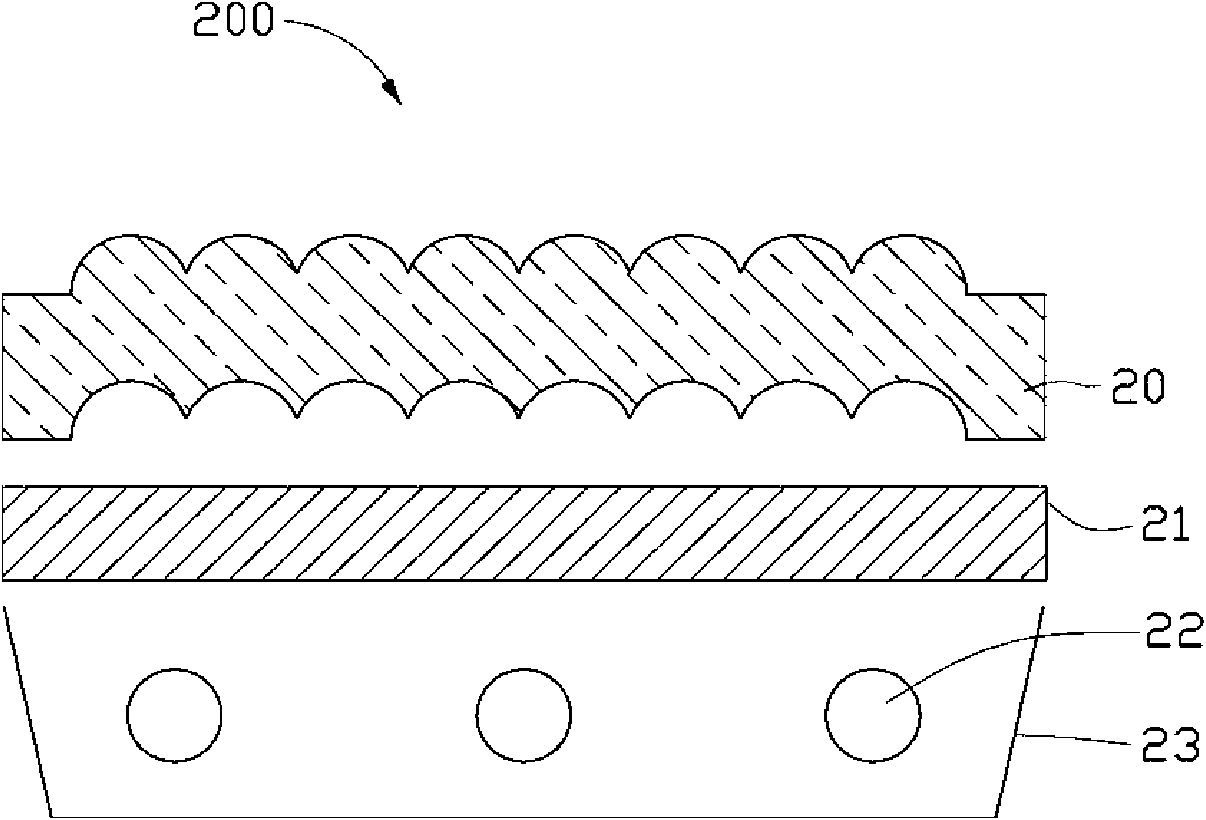

[0016] See image 3 , Shown is the backlight module 200 of the first preferred embodiment of the present invention, which includes an optical plate 20 and a diffuser plate 21 arranged on one side of the optical plate 20, a plurality of light sources 22, and a frame 23 for accommodating the plurality of light sources 22 The light emitted by the light source 22 enters the diffuser plate 21 directly or reflected by the frame 23, and enters the optical plate 20 after being diffused by the diffuser plate 21 for focusing.

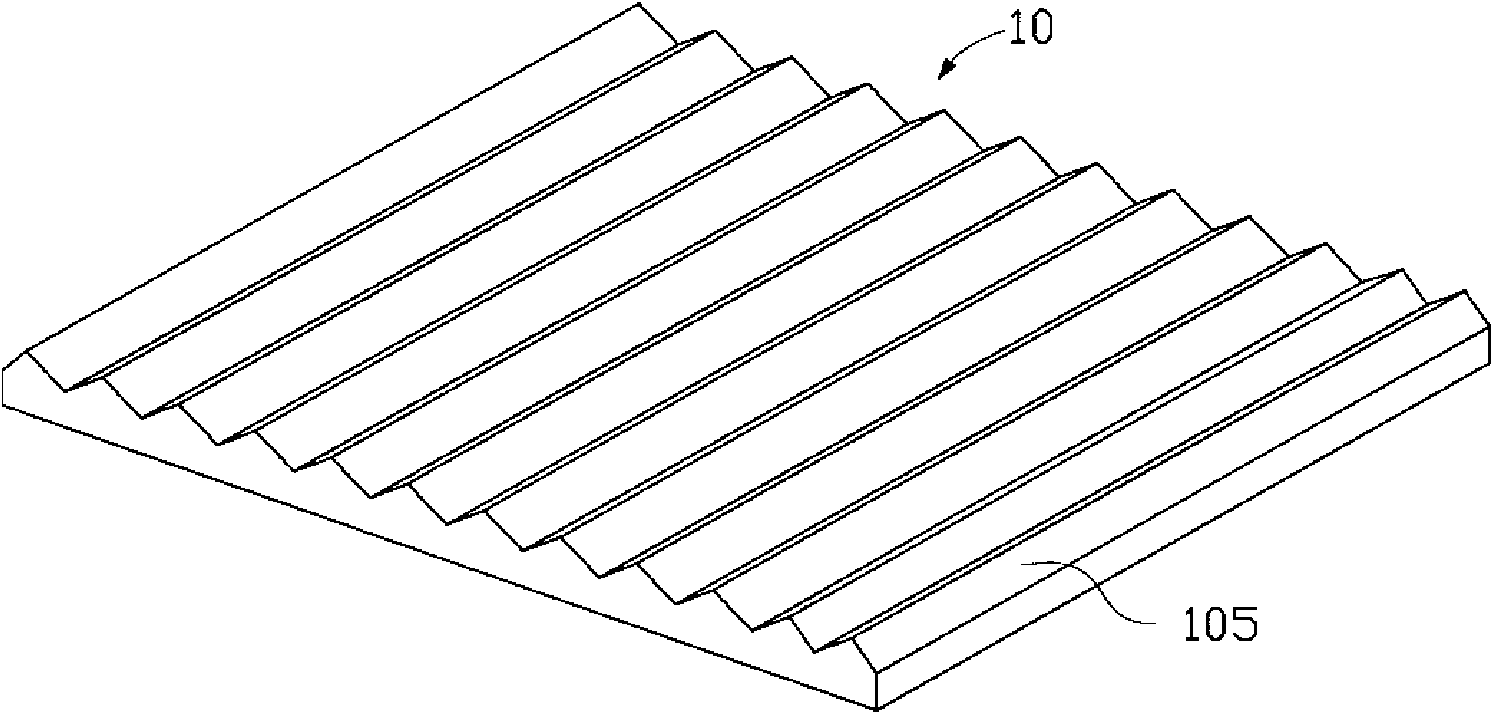

[0017] See Figure 4 The optical plate 20 is composed of a transparent body, and the transparent body includes a first surface 201 and a second surface 203 opposite to the first surface 201. The first surface 201 has a plurality of elongated arc-shaped grooves 202, and the second surface 203 has a plurality of elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com