OLED splicing display screen

A technology for display screen and image display area, applied in the field of OLED display, can solve the problems of low yield rate, high manufacturing cost and low yield rate of mass production, and achieve the effect of high yield rate, low cost and large display size of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

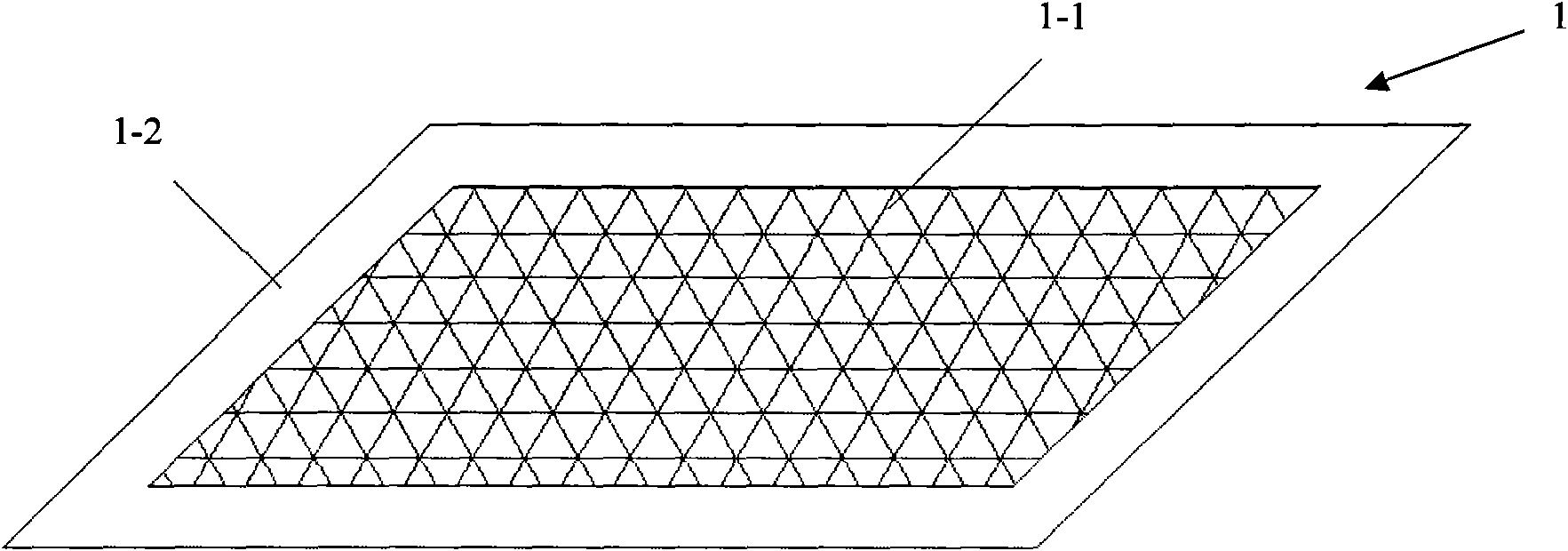

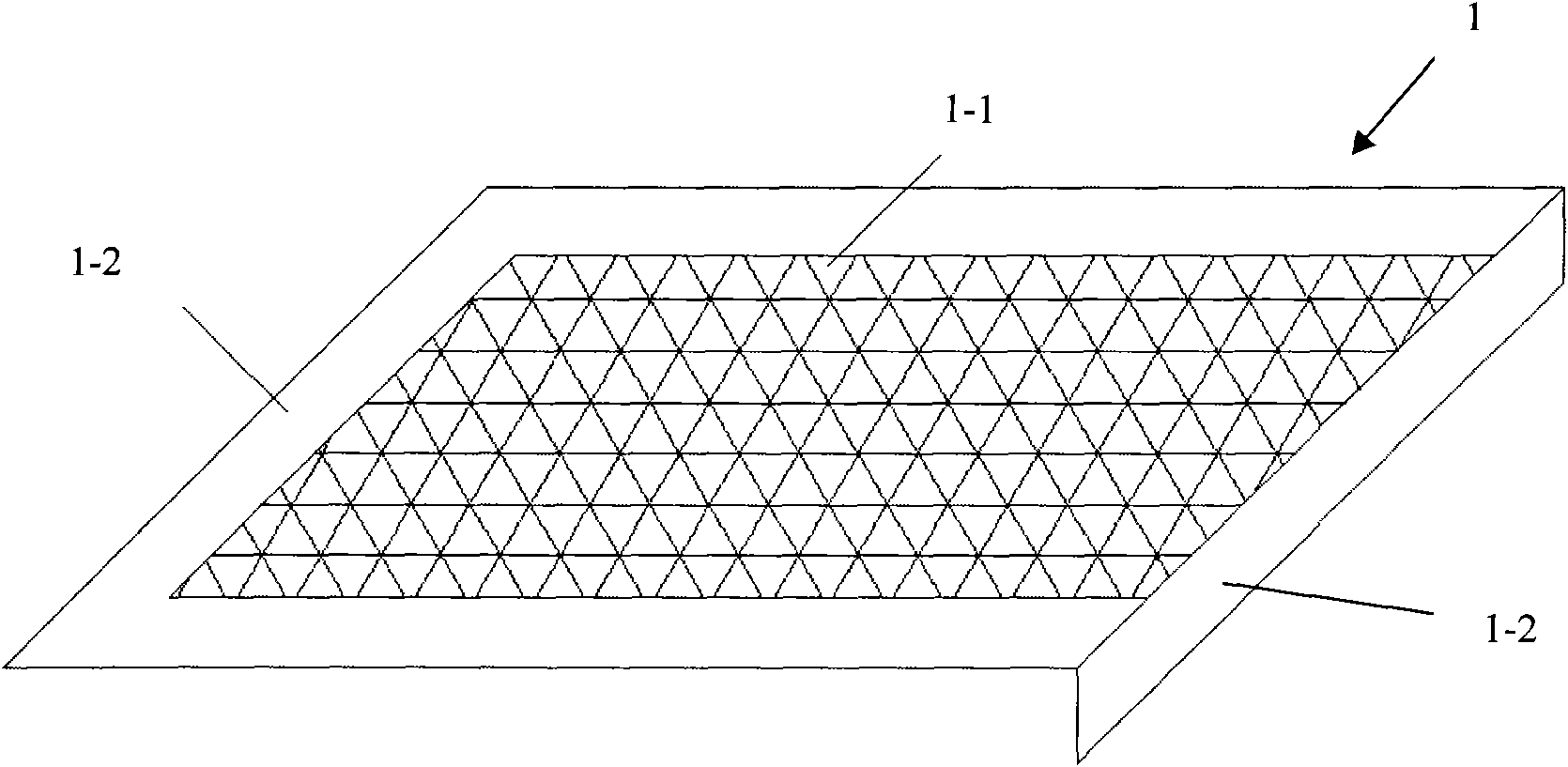

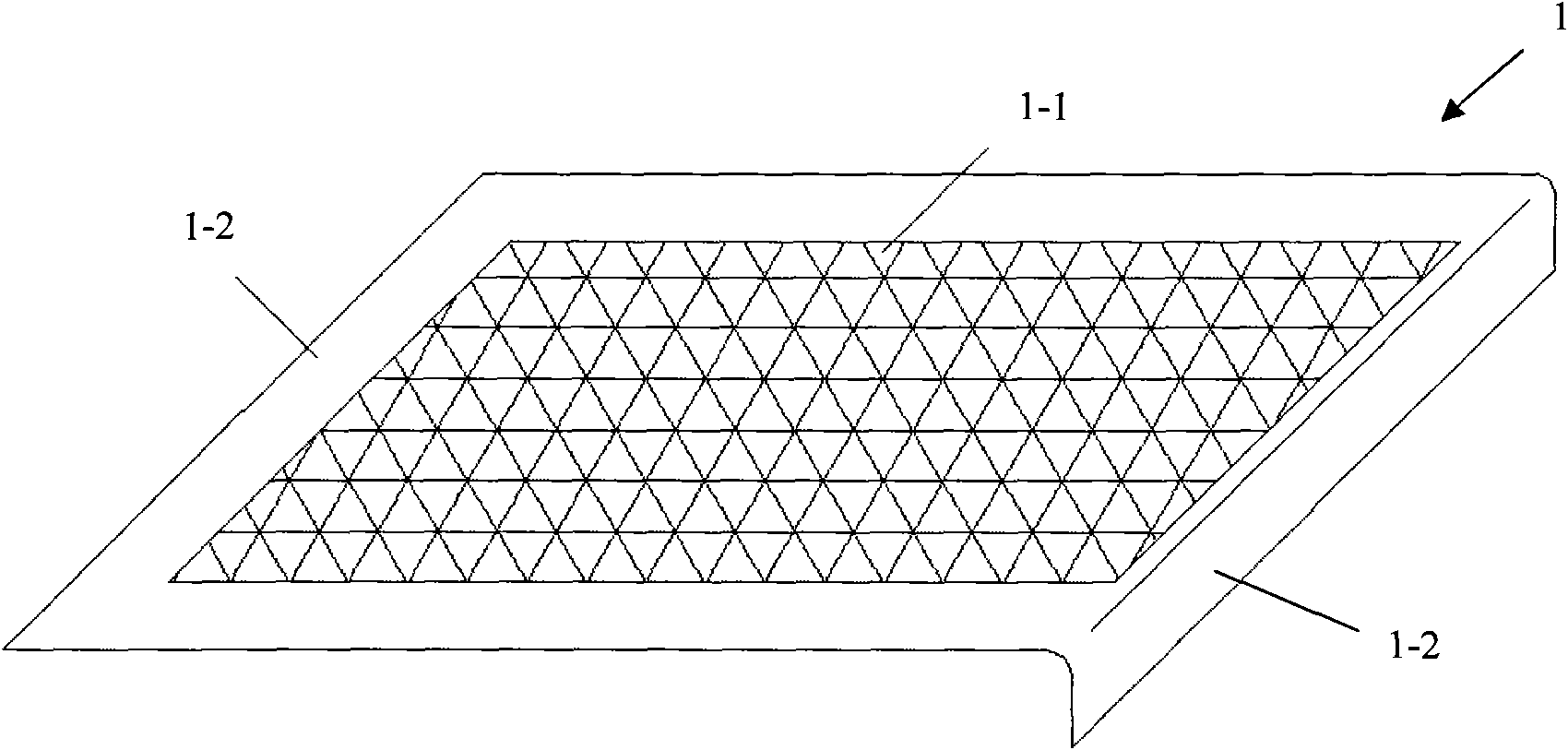

[0023] like Figures 1 to 8 As shown, the OLED splicing display screen of the present invention includes a support body 4 and a plurality of OLED display screens. The OLED display screens are soft OLED display screens 1 or hard OLED display screens 1-3. Spliced and placed on the support body 4, the support body 4 is provided with a data line port 5, the driving circuit of the OLED display is arranged inside or on the back of the OLED display, and the connection terminal 2 of the OLED display is arranged On the back side of the OLED display screen, the drive circuit is sequentially connected to the connection terminal 2 and the data line port 5 through a wire 3; the OLED display screen is a soft OLED display screen 1 (the soft OLED display screen 1 includes an image display area 1 -1 and no image display area 1-2), then the no image display area 1-2 of each soft OLED display 1 is set as a bending portion bent to the back of the soft OLED display 1 at a certain angle, each Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com