Clothing print method employing ink jet printer and clothing print system

A technology of inkjet printer and printing method, applied in printing, typewriter, dyeing method, etc., can solve the problem of difficult T-shirt printing, etc., and achieve the effect of beautiful printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, an embodiment of a T-shirt printing system to which the present invention is applied will be described with reference to the drawings.

[0030] (the whole frame)

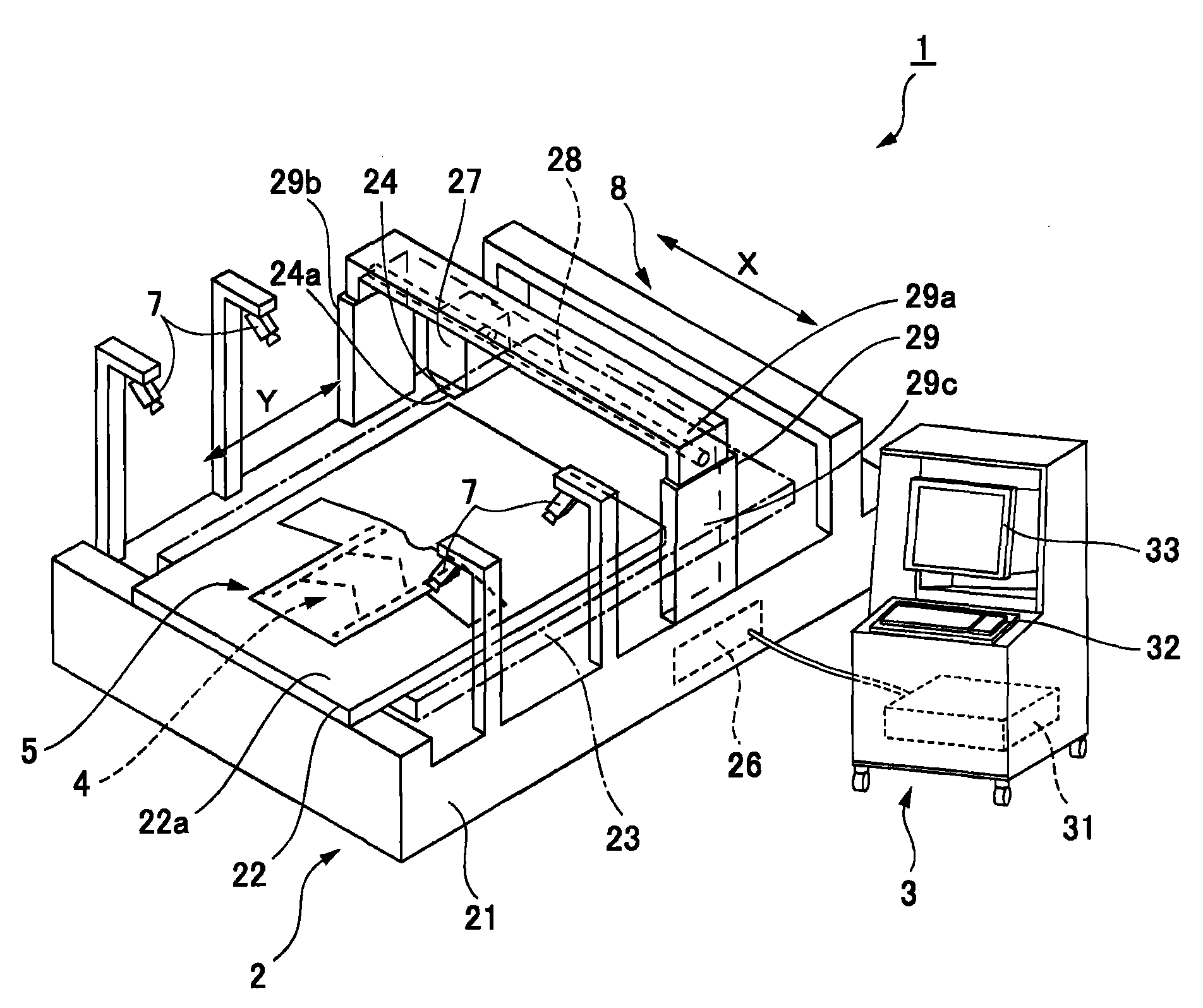

[0031] figure 1 It is the overall structure diagram of the T-shirt printing system. The T-shirt printing system 1 includes an inkjet printer 2 , a printer control device 3 , and a T-shirt stretcher 4 .

[0032] The inkjet printer 2 has: a rectangular device stand 21, a vertically long rectangular medium mounting table 22 horizontally supported by the device stand 21 in a state capable of reciprocating movement in the front-rear direction (Y direction) of the printer, A transport mechanism 23 for transporting the medium mounting table 22, an inkjet head 24 for printing on the T-shirt 5 mounted on the medium mounting table 22, and a drive control unit 26.

[0033] The inkjet head 24 is mounted on the carriage 27 with the ink nozzle surface 24a facing downward. The carriage 27 can reciprocate in the X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com