Engine speed control system for work vehicle

A technology of engine speed and control system, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc. It can solve the problems of engine output speed increase, achieve the effect of weakening slipping, getting rid of slipping state easily, and improving control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, as an example of the best mode for implementing the present invention, an embodiment in which the engine speed control system for a work vehicle according to the present invention is applied to a tractor, which is an example of a work vehicle, will be described with reference to the drawings.

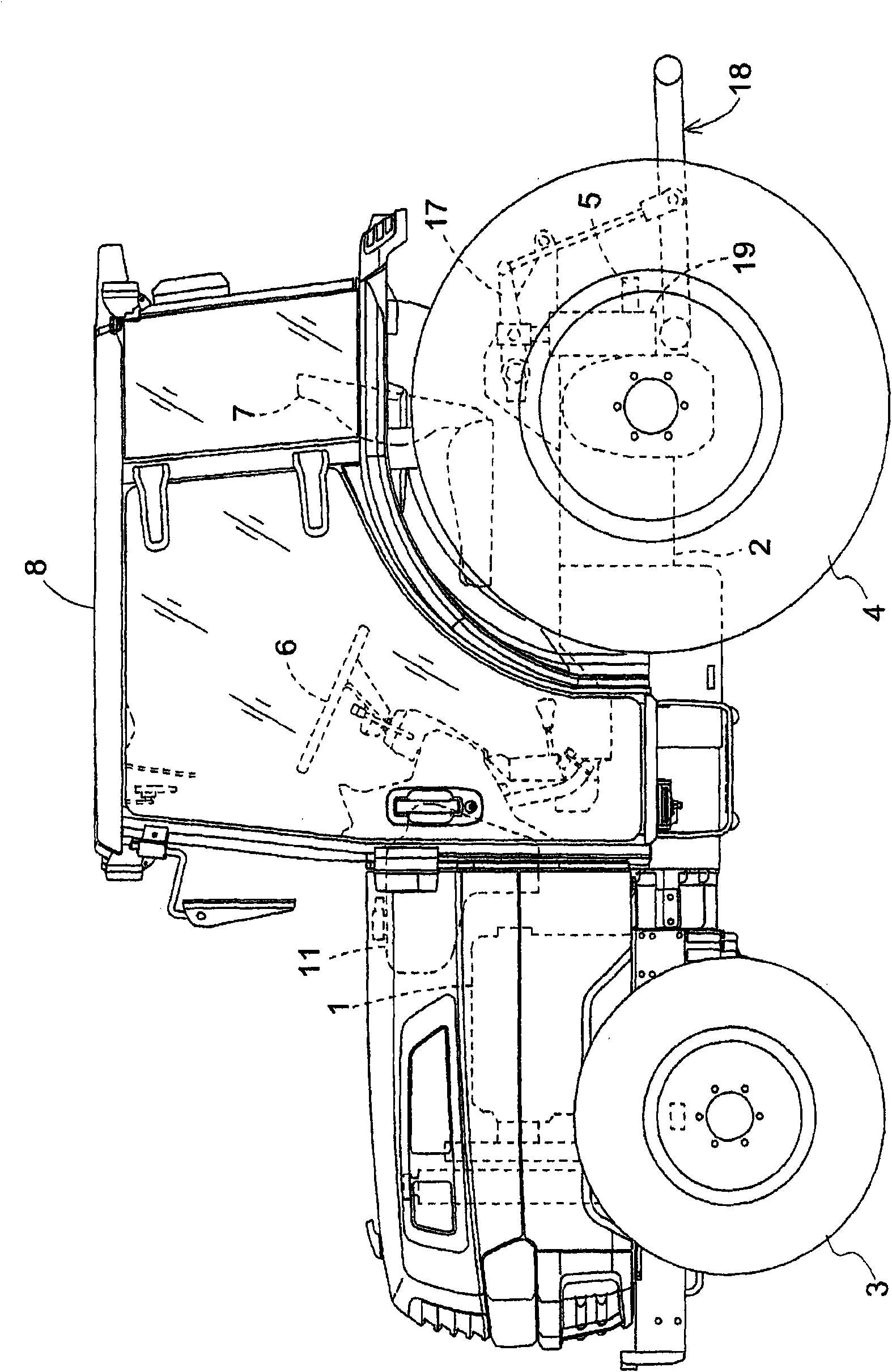

[0031] figure 1 is the overall side view of the tractor. This tractor has an engine 1 mounted on its front. The rotational power output by the engine 1 is transmitted to a pair of left and right front wheels via a clutch (not shown) that interrupts the rotational power, a transmission device (not shown) built into a transmission case 2 also serving as a frame, etc. 3 and the rear wheel 4, and the power take-off shaft 5 protruding from the rear portion of the gearbox 2 toward the rear. A steering wheel 6 for front wheel steering, a driver's seat 7 , etc. are provided at the rear of the tractor to form a boarding and driving section 8 , and a cab (cabin) 9 covering the boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com