Extracting device and method thereof

A cylinder and area technology, applied in the field of extraction devices for isolating impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

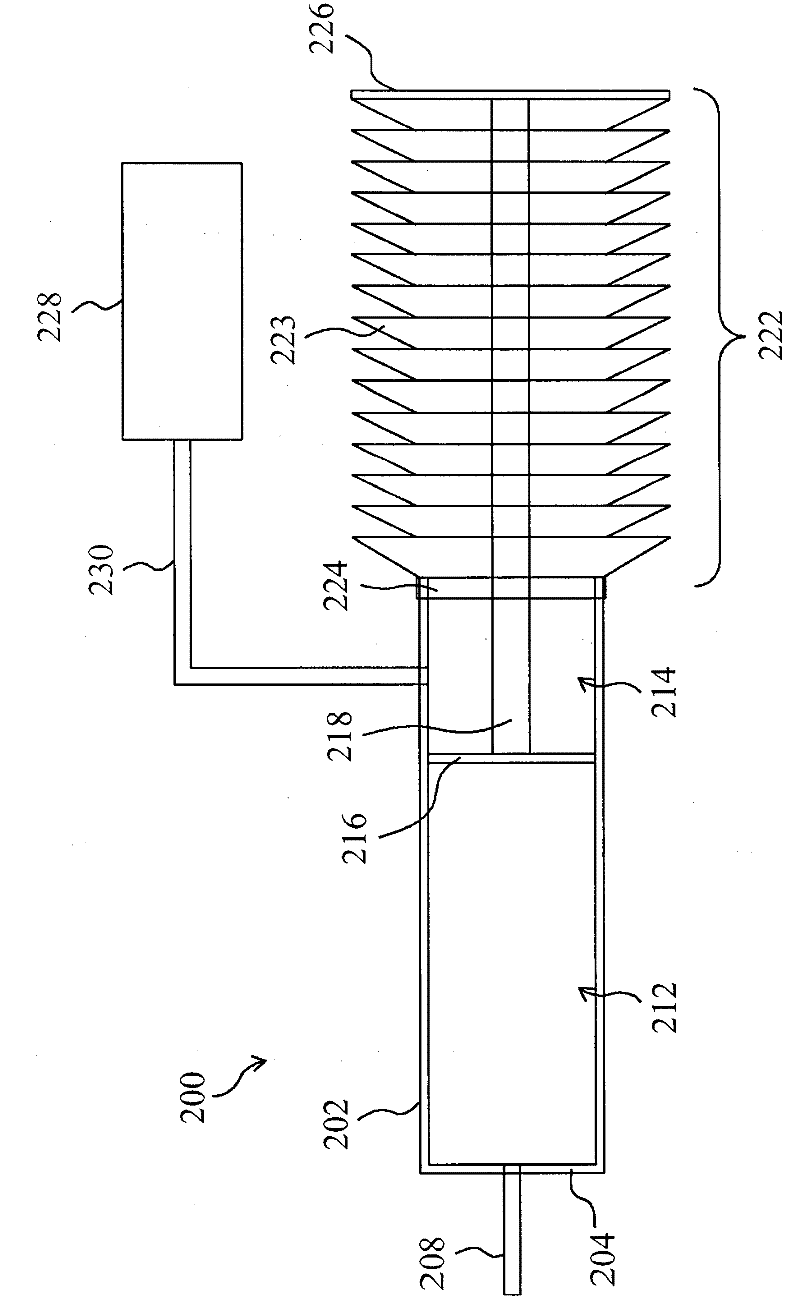

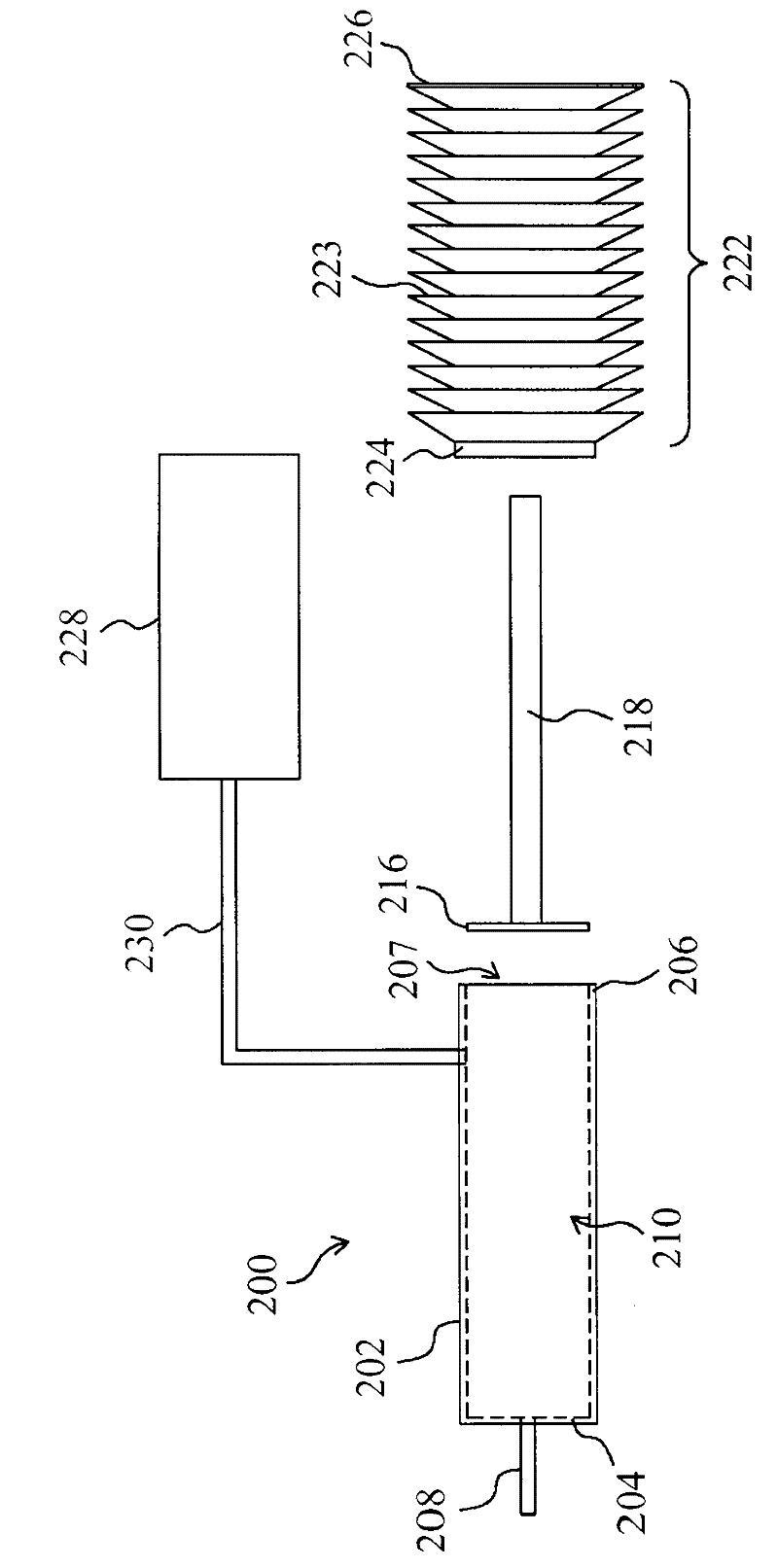

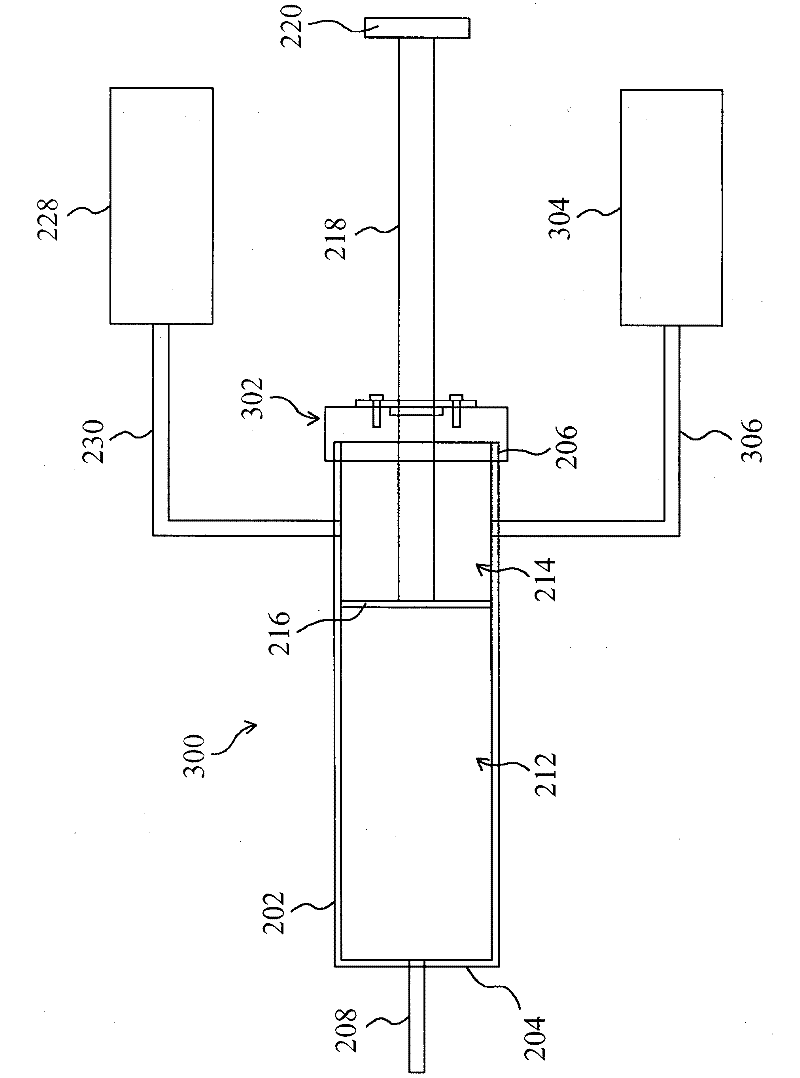

[0075] see now figure 2 with image 3 , figure 2 is a schematic diagram of the first embodiment of the extraction device of the present invention, image 3 yes figure 2 exploded view. As shown in the figure, the extraction device 200 includes a cylinder 202, which includes a hollow chamber 210 and an opening 208. The hollow chamber 210 has an opening 207 at the end 206 of the cylinder 202, and the opening 208 is located at the front end of the cylinder 202. 204 communicates with the hollow chamber 210, a piston 216 is located in the hollow chamber 210, its edge is in contact with the wall of the hollow chamber 210, and the hollow chamber 210 is divided into two regions 212 and 214, and the region 212 is between the piston 216 and the wall of the hollow chamber 210. Between the front ends 204 of the barrel 202, the opening 208 communicates with the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com