Core switching and sealing system of valve

A sealing system and switch technology, applied in shaft seals, valve details, valve devices, etc., can solve the problems of separation of plastic gaskets and valve stems, increased manufacturing costs, and reduced valve service life, and achieve simple structural design and production costs. The effect of raising the production cost will not be

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

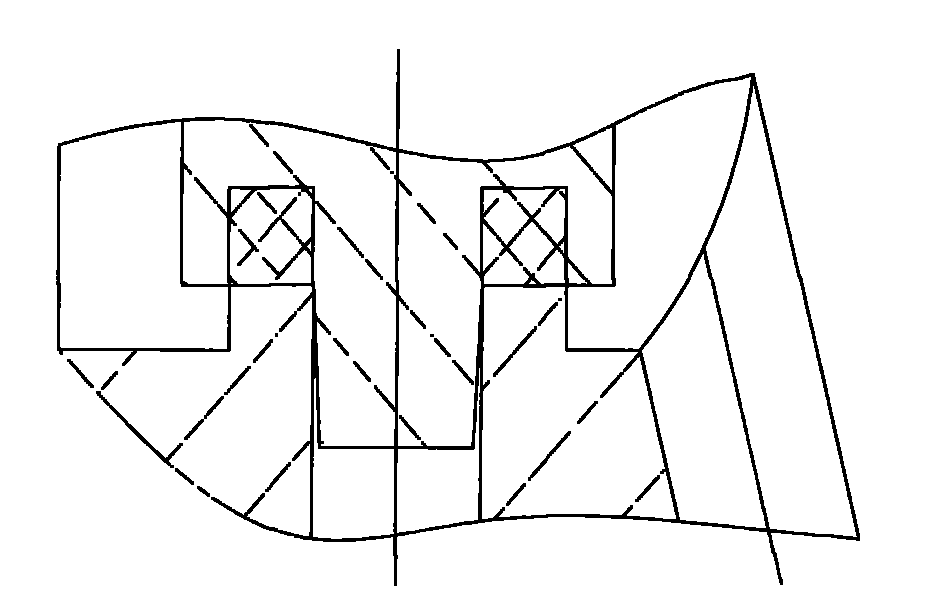

[0043] Embodiment 1 of the present invention provides a core switch sealing system for valves. The core sealing systems of other valves, such as solenoid valves, toggle switch valves, safety valves, back pressure valves, and pressure-stabilizing valves, are all Within the scope of protection of the present invention, this embodiment 1 takes the globe valve as an example to illustrate the sealing system, which specifically includes: a valve stem with an annular groove, and a plastic gasket with a volume equal to that of the annular groove piece;

[0044] The cavity of the annular groove is larger and the opening is smaller, which is used to completely clamp the plastic gasket in the annular groove;

[0045] The thickness of the plastic gasket is equal to the depth of the annular groove, and it is used to cooperate with the annular groove to complete the sealing of the globe valve.

[0046] Among them, since the volume of the plastic gasket and the annular groove are equal, the...

Embodiment 2

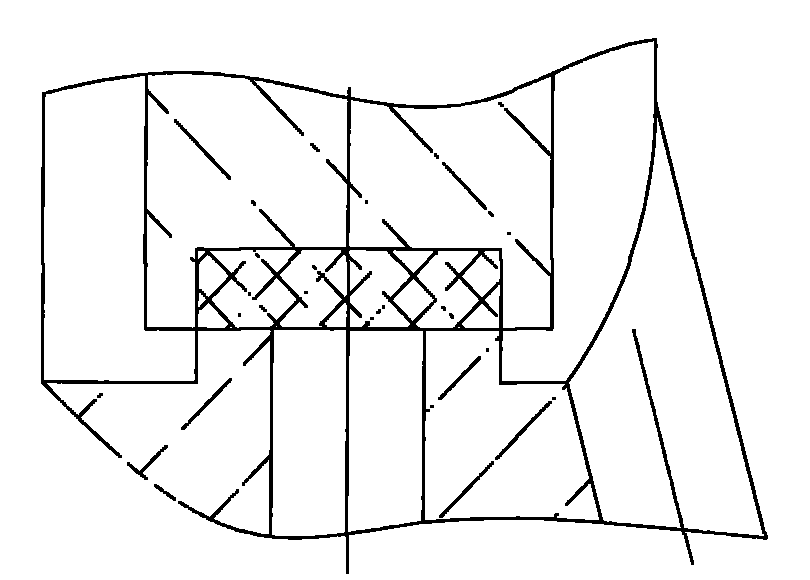

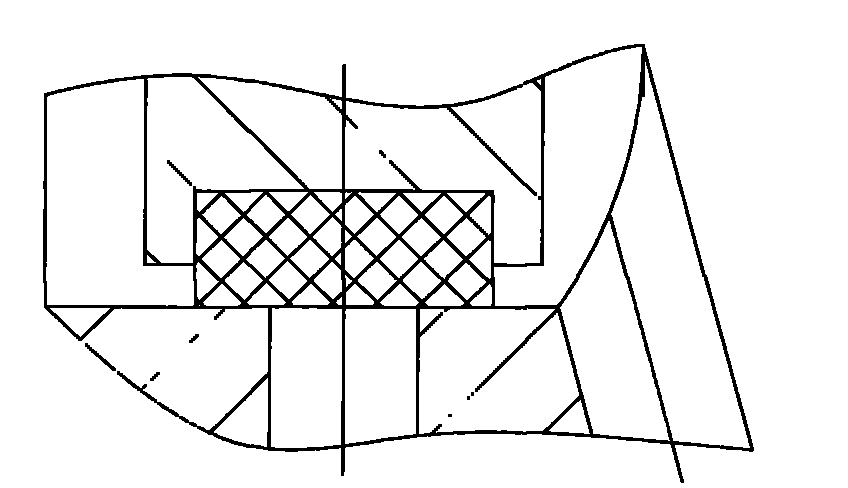

[0049]Embodiment 2 of the present invention provides a sealing system for valves. The core sealing systems of other valves, such as solenoid valves, toggle switch valves, safety valves, back pressure valves, and pressure regulator valves, are all in this valve. Within the protection scope of the invention, the second embodiment takes the stop valve as an example to describe the sealing system. see Figure 12 , the sealing system specifically includes: a valve stem 121 with an annular groove and a plastic gasket 122; wherein, the volume of the annular groove on the valve stem 121 is equal to that of the plastic gasket 122, and the depth of the annular groove is equal to that of the plastic gasket of equal thickness. Wherein, the annular groove has a larger cavity and a smaller opening, and the plastic gasket cooperates with the annular groove to complete the sealing function.

[0050] see Figure 13 , the outer wall surface of the annular groove of the valve stem 121 is a ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com