Gradient divisional colour change control method for liquid crystal sunglasses and control device thereof

A control method and technology for sunglasses, applied in the field of sunglasses, can solve the problems of poor practicability, affecting sight, and no commercialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

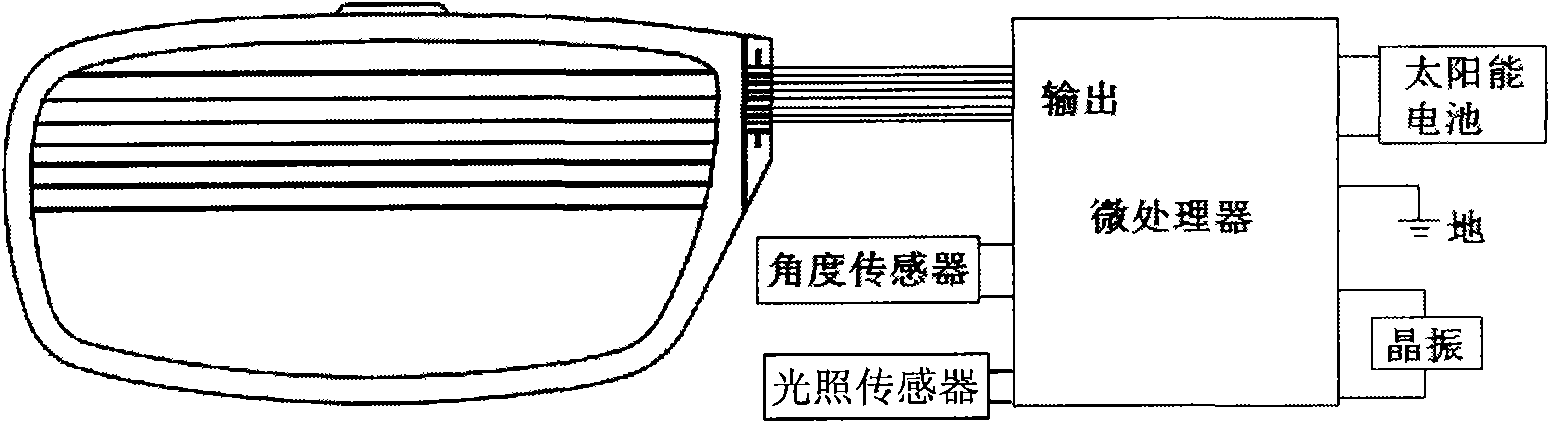

[0026] see figure 1 Schematic diagram of the structure of this example.

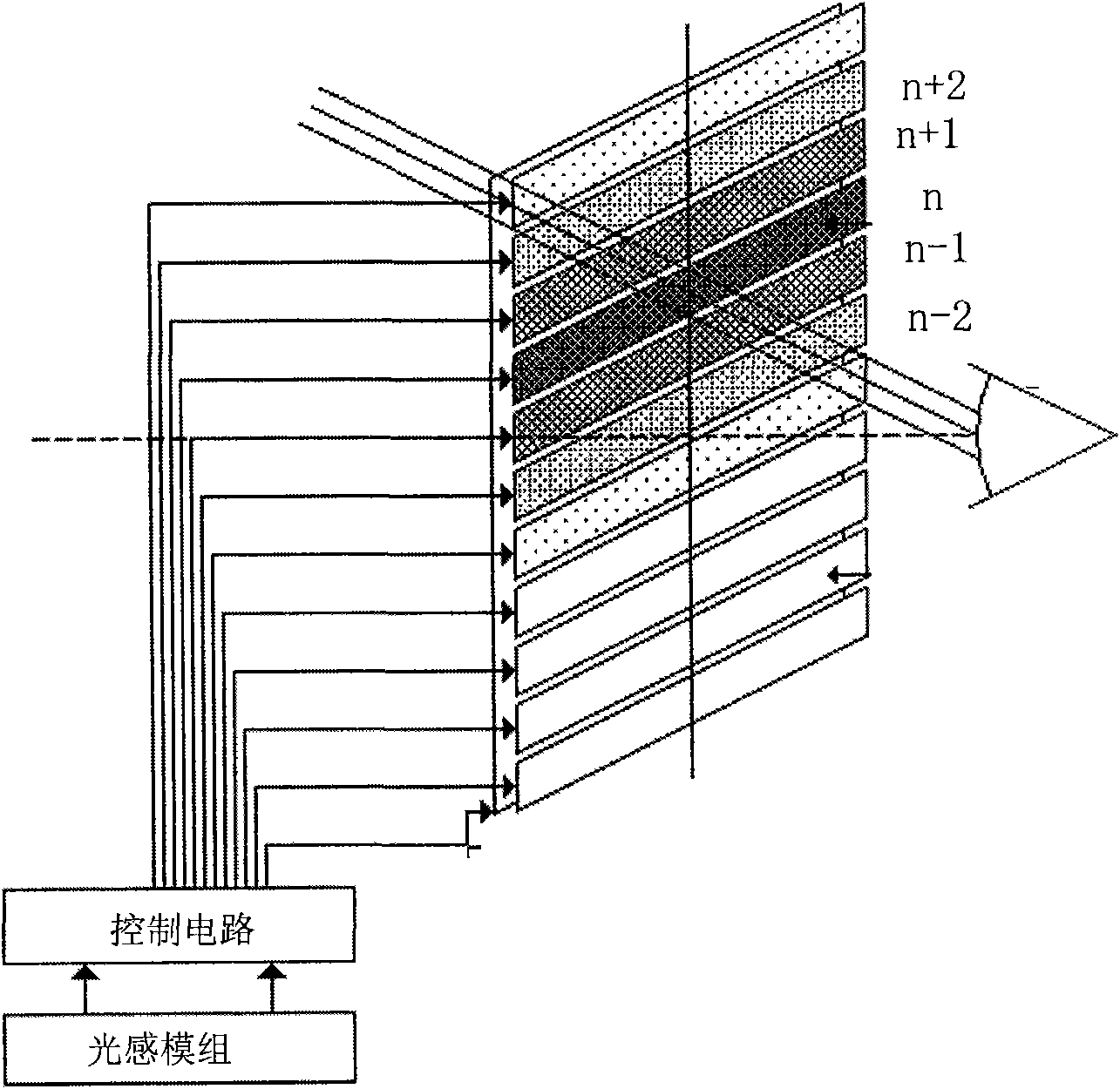

[0027] The liquid crystal lens is provided with a number of horizontal liquid crystal strips distributed up and down and parallel to each other;

[0028] The controller adopts a digital integrated CPU chip of the microprocessor MSP430F2234 type, which is welded on the printed circuit board and electrically connected with other components through the printed circuit board.

[0029] The input terminal of the CPU chip is connected with an optical angle sensor and an illumination sensor, and its multiple output control pins are respectively electrically connected to the control electrodes of each liquid crystal bar on the liquid crystal lens, and its common electrode pin is electrically connected to the common electrode of each liquid crystal bar. connected, the solar cell supplies power to the CPU chip, the light angle sensor and the light sensor through the printed circuit board.

[0030] The microproces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com