Shunt-type filtering device with back wash function

A filter device and shunt-type technology, which is applied to fixed filter elements, filter separation, separation methods, etc., can solve the problems of impurity embedded filter mesh blockage, incomplete flushing, high failure rate, etc., and achieve easy automatic control, The effect of thorough washing of impurities and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

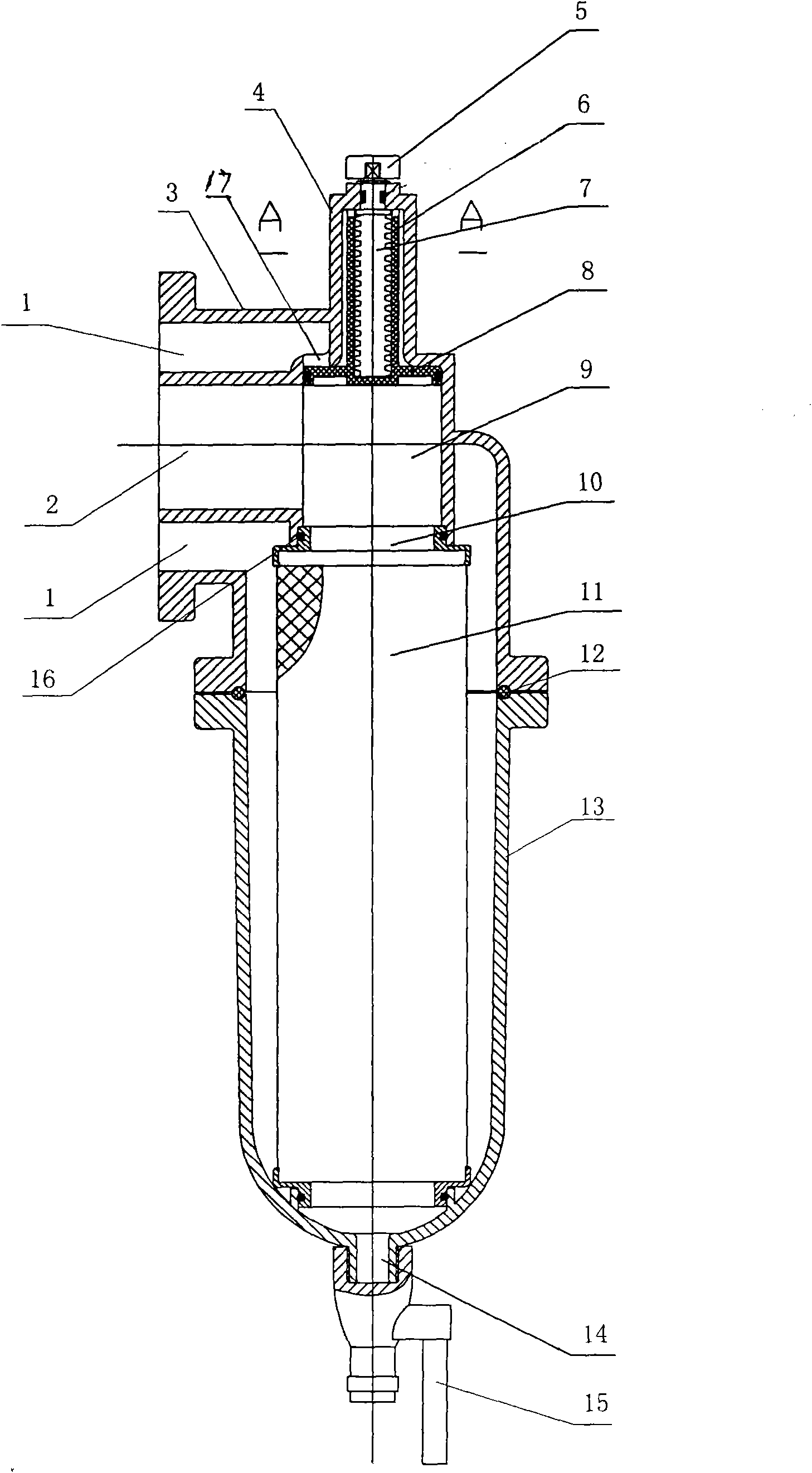

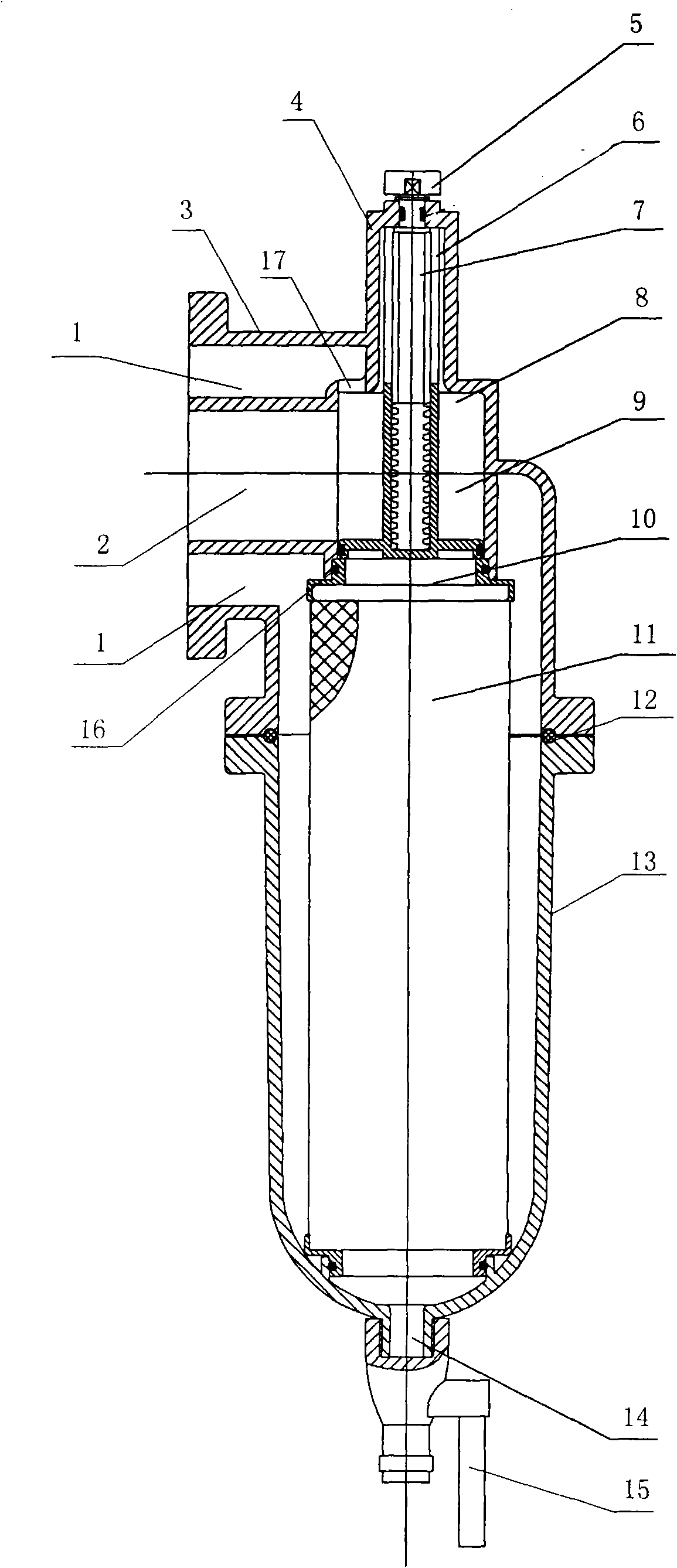

[0018] Refer to attached Figure 1~4 , the shunt filter device with backwashing includes a control valve, a filter bottle 13, a filter element 11 and a drain valve 15, the control valve is installed on the upper part of the filter bottle 13, the filter bottle 13 is equipped with a filter element 11, and the lower part of the filter bottle 13 is equipped with a drain valve 15 . A sealing ring 12 is installed between the control valve and the filter bottle 13

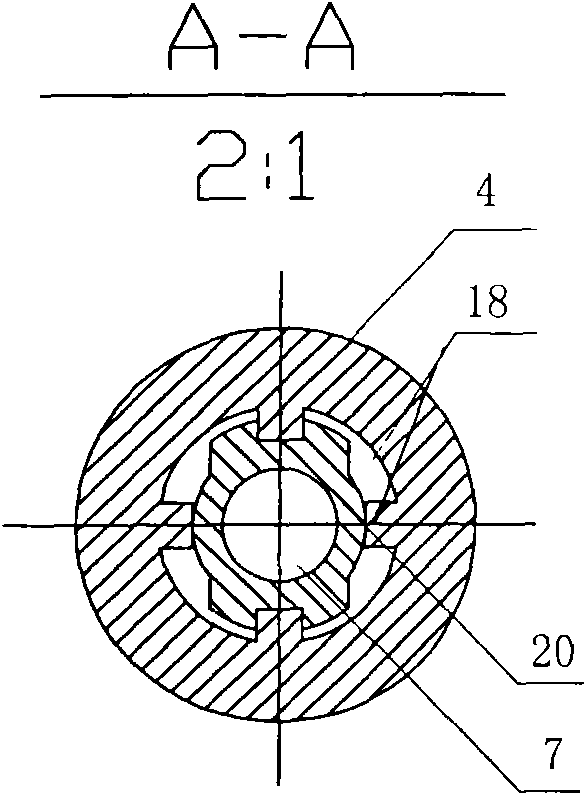

[0019] The control valve has a valve body 3, a piston cylinder 9 is arranged in the valve body 3, a liquid inlet 2 and a liquid outlet 1 are arranged on one side of the valve body 3, a valve head 4 is arranged on the upper part of the valve body 3, and a valve head 4 is arranged in the valve head 4 Cavity is equipped with screw sleeve 6, and screw rod 7 is housed in screw sleeve 6, and piston 8 is equipped with in the bottom of screw rod 7, and piston 8 is contained in the piston cylinder 9, can move up and down along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com