Method for treating coal gasification wastewater containing phenol and ammonia

A technology for coal gasification wastewater and phenolic ammonia, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, degassed water/sewage treatment, etc. problems, to ensure long-term stable operation, alleviate the problems of ammonia salt crystallization and scaling, and improve the removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

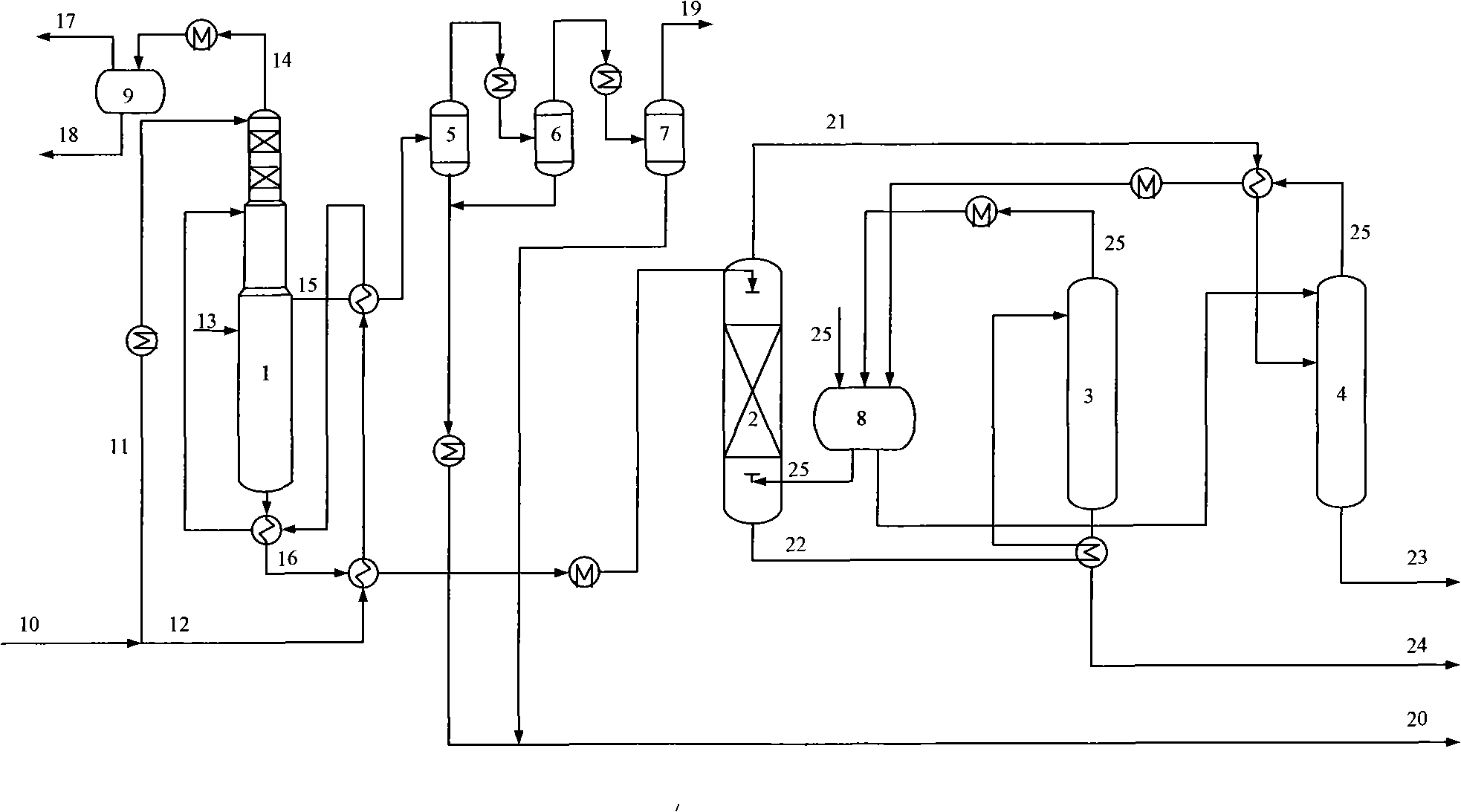

Embodiment 1

[0027] In this example, the above-mentioned device for treating phenamine-containing coal gasification wastewater is used for wastewater treatment. The total phenol content of coal gasification sewage is 6010mg·L -1 , free ammonia 12.61g·L -1 , fixed ammonia 0.60g·L -1 , CO 2 4.26g·L -1 , the pH value is 9.8, the water temperature is 87°C, the flow rate is 92.64 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripping tower is 1:3.6, the tower top temperature is 45.86°C, the tower top pressure is 0.47MPa, the tower bottom temperature is 157°C, the tower bottom pressure is 0.47MPa, and the mass percentage concentration is 20% caustic soda The flow rate of aqueous solution is 380kg·hr -1 , the temperature of side stream production is 140.0°C and the pressure is 0.46MPa. The operating pressure of the first-stage partial condenser in the three-stage partial condenser is 0.40MPa, and the operating temperature is 137.7°C; the operati...

Embodiment 2

[0029] In this example, the above-mentioned device for treating phenamine-containing coal gasification wastewater is used for wastewater treatment. The total phenol content of coal gasification sewage is 6050mg·L -1 , free ammonia 20.43g·L -1 , fixed ammonia 1.34g·L -1 , CO 2 2.83g·L -1 , the pH value is 11.0, the water temperature is 89°C, the flow rate is 60.01 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripper is 1:4.0, the tower top temperature is 41.14°C, the tower top pressure is 0.48MPa, the tower bottom temperature is 161.7°C, the tower bottom pressure is 0.51MPa, and the 60% (mass) lye is 120kg·hr -1 , the temperature of the side line production is 151.0°C, and the pressure is 0.49MPa. The operating pressure of the first stage partial condenser is 0.40MPa, the operating temperature is 144.8°C, the operating pressure of the second stage partial condenser is 0.36MPa, the operating temperature is 97.2°C, and the opera...

Embodiment 3

[0031] In this example, the above-mentioned device for treating phenamine-containing coal gasification wastewater is used for wastewater treatment. The total phenol content of coal gasification wastewater is 5415.9mg·L -1 , free ammonia 19.66g·L -1 , fixed ammonia 0.37g·L -1 , CO 2 3.94g·L -1 , the pH value is 10.5, the water temperature is 85°C, the flow rate is 85.4 tons / hour, according to figure 1 process shown. The cold and hot feed ratio of the sewage stripper is 1:3, the tower top temperature is 40.6°C, the tower top pressure is 0.50MPa, the tower bottom temperature is 165°C, the tower bottom pressure is 0.52MPa, and the 20% (mass) lye is 350kg·hr -1 , the temperature of the side line production is 152.0°C, and the pressure is 0.50MPa. The operating pressure of the first stage partial condenser is 0.42MPa, the operating temperature is 145°C, the operating pressure of the second stage partial condenser is 0.39MPa, the operating temperature is 79.69°C, and the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com