Corrugated medium pulping wastewater treatment technology

A technology for pulping wastewater and treatment process, which is applied in the direction of processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve problems such as high temperature, environmental pollution, and poor biodegradability, and achieve Saving resources and energy, reducing dosage, and emphasizing the effect of regulating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments.

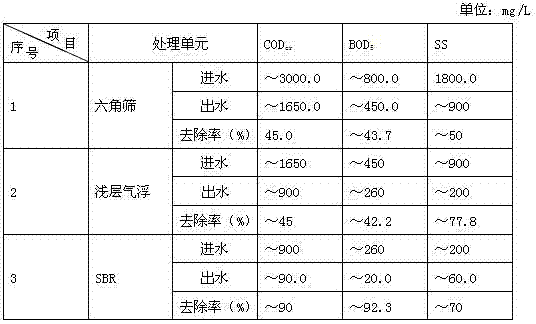

[0019] The quality index of wastewater discharged from a production plant of a paper company:

[0020] List of Wastewater Sources and Water Quality and Quantity

[0021] serial number project Water volume (m 3 / d) COD cr (mg / L) BOD 5 (mg / L) SSmg / L) pH 1 70,000 tons of containerboard mixed wastewater (pulping and papermaking) 6000 ~3000 ~800 ~1800 7~8 2 air flotation into water 1500~1800 ~450 ~900 7~8 3 Air floating out of water 800~900 240~270 ~200

[0022] Treatment process of the present invention is:

[0023] A process for treating corrugated base paper pulping wastewater, comprising the following steps:

[0024] (1) Pulping waste water is removed through the cyclone sand settler to remove the settleable sediment in the waste water, and the effluent flows into the waste water treatment stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com