Electric iron

An electric iron and ironing technology, applied in hand irons, textiles, papermaking, instruments, etc., can solve the problems that the iron cannot generate steam to iron deep wrinkles, cannot clearly observe the details of the fabric, and cannot enlarge the details, etc., to achieve ironing The ironing process is clear, the structure is simple and reasonable, and the effect of achieving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

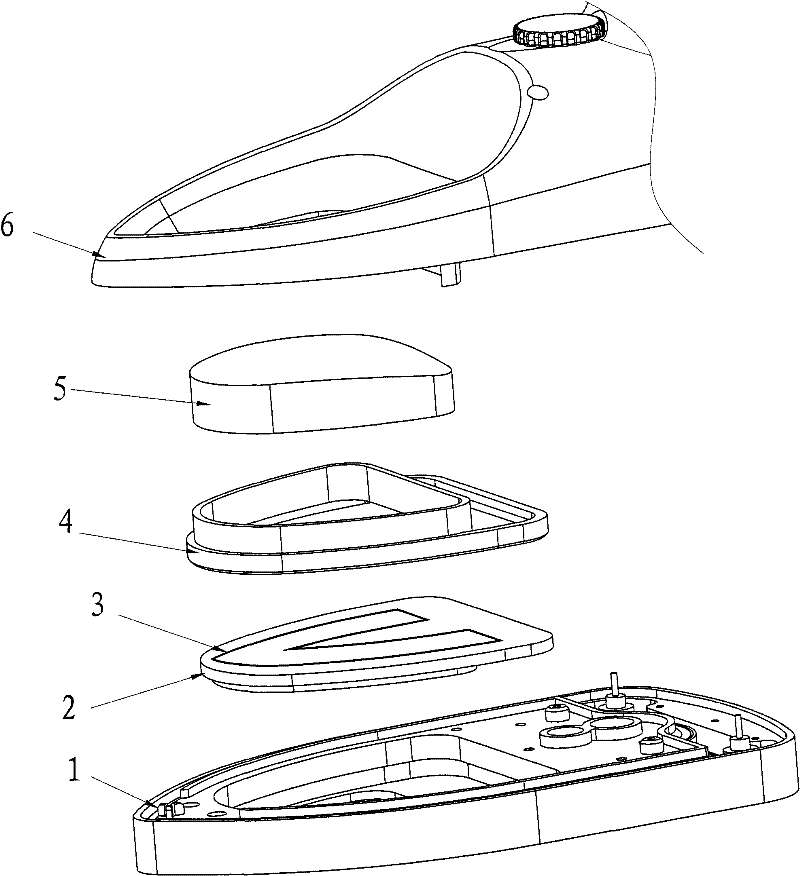

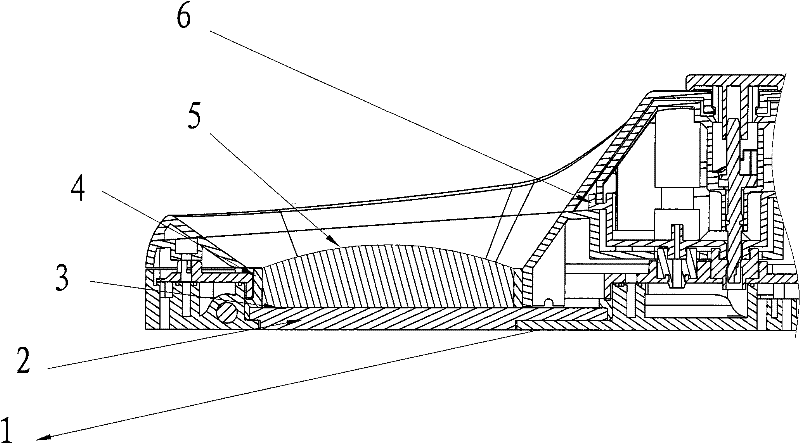

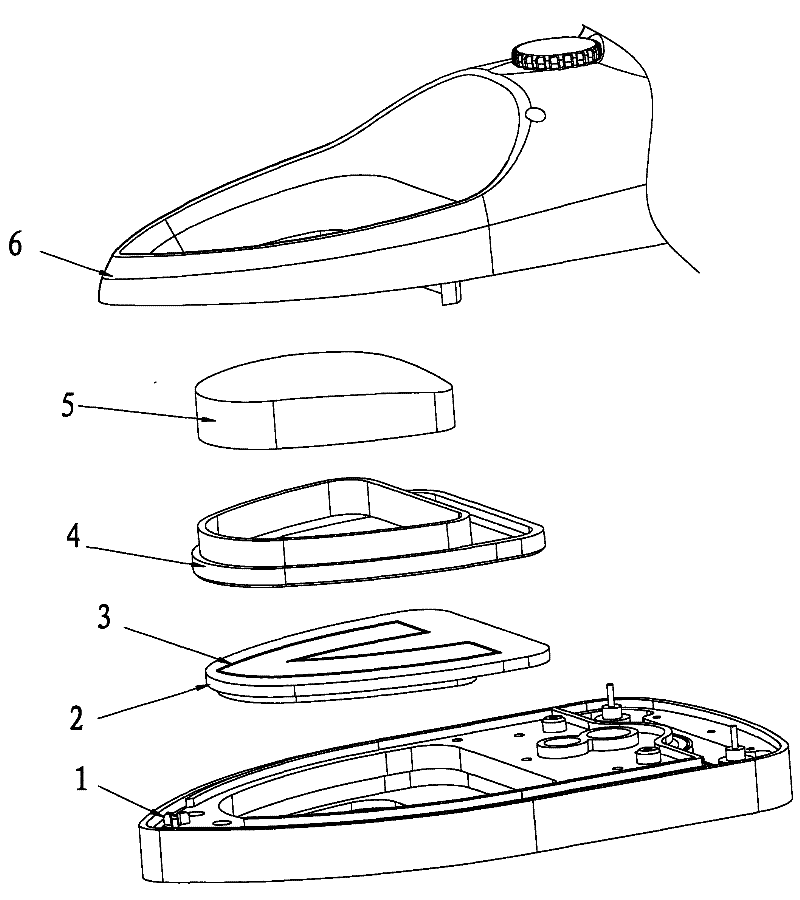

[0019] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes a heating base plate 1, an upper cover 6 and a control circuit arranged in the iron, wherein the heating base plate 1 is inlaid with a transparent observation cover 2, and the transparent observation cover 2 is provided with a heat source 3, and the heat source 3 is connected to the The control circuit inside the iron is connected.

[0020] In this embodiment, in order to better observe the ironing of the clothes and make the ironing process clearer, a magnifying glass 5 is also arranged above the transparent observation cover 2 . For the convenience of installation, the above-mentioned magnifying glass 5 is installed on the transparent observation cover 2 through the positioning piece 4 .

[0021] In order to make the ironing effect better, the heating soleplate 1 is a heating soleplate capable of generating steam, and the bottom surface of the transparent observation cover 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com