Turning gasket for connecting flanges

A technology of gaskets and flanges, which is applied in the field of direction-changing gaskets for flange connections, can solve problems such as poor versatility, large angles, and difficult manufacturing and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

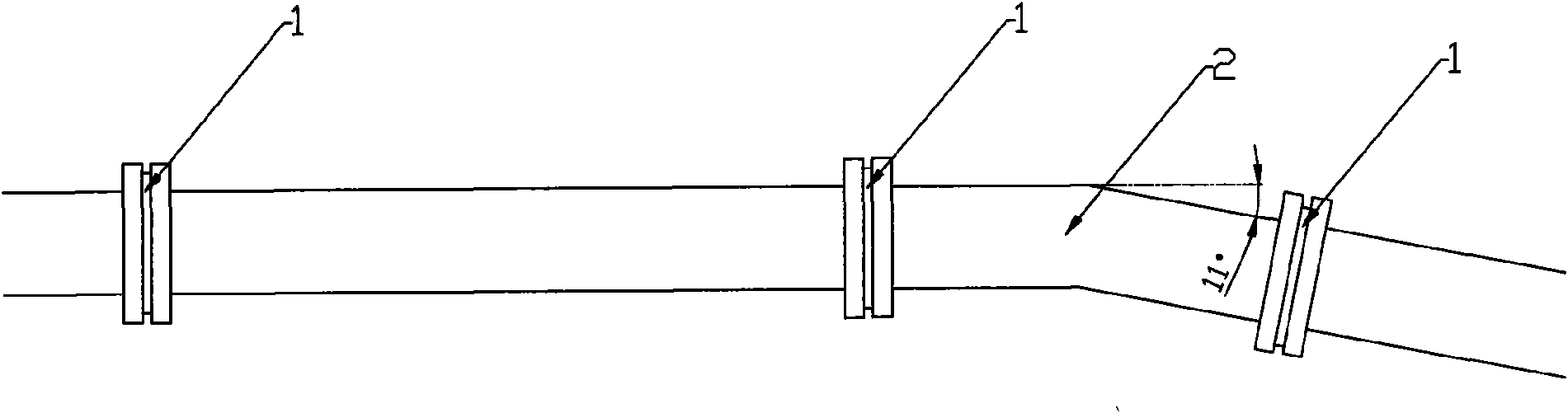

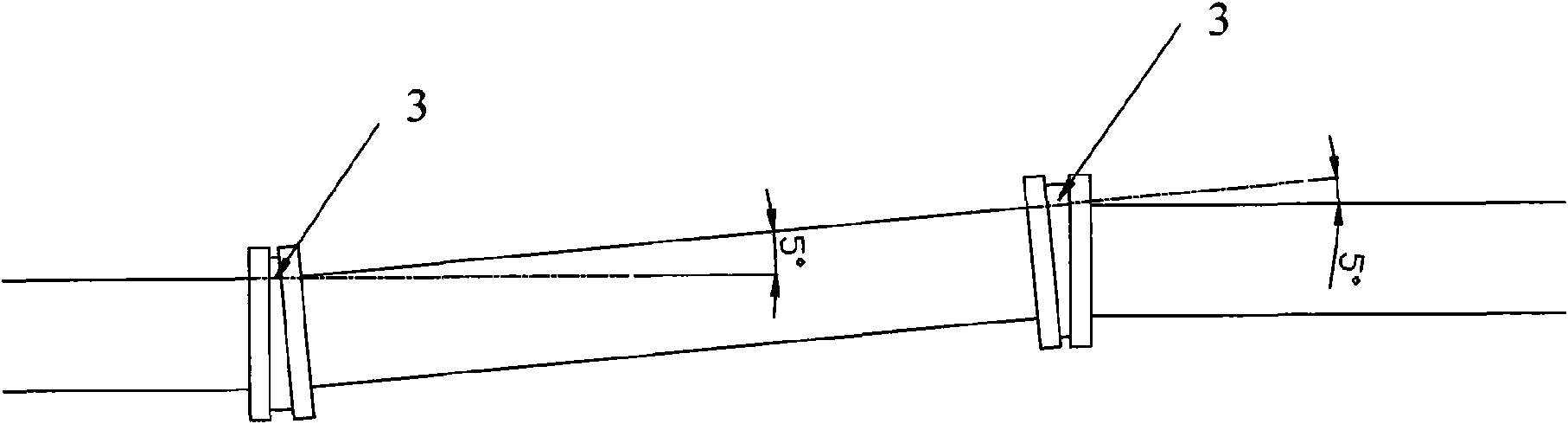

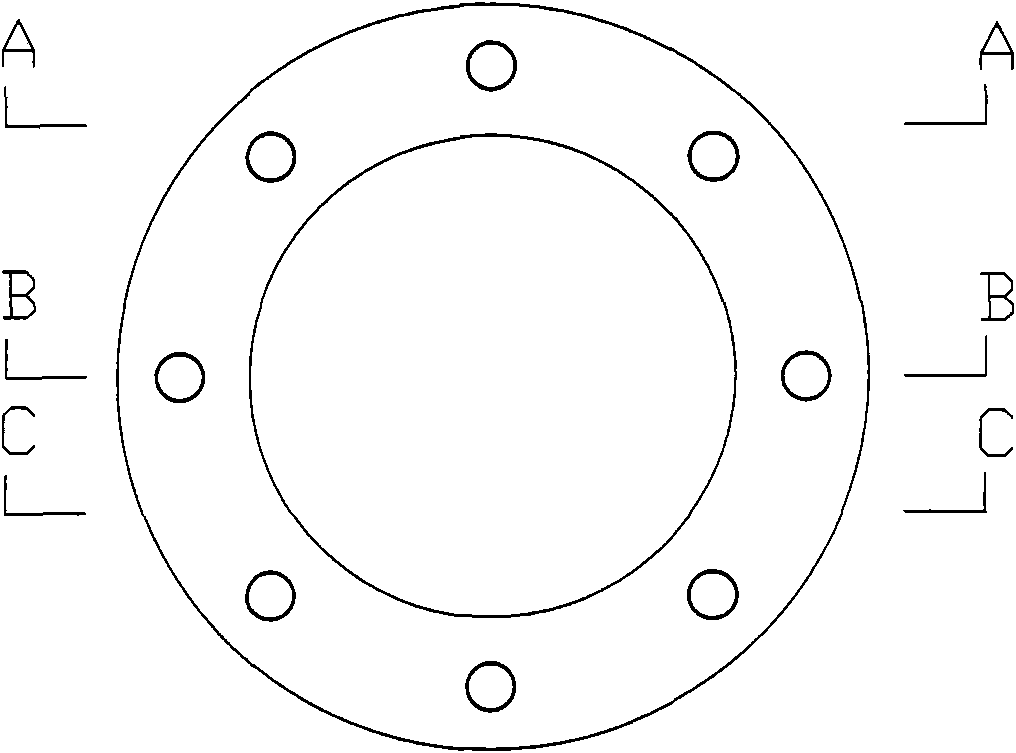

[0022] Such as Figure 2 to Figure 8 As shown, the direction-changing washer 3 for flange connection of the present invention includes a washer body, wherein the extension lines of the connecting planes on both sides of the washer body intersect to form an included angle, and the included angle is less than 90 degrees. This angle determines the corner of the pipe. The above-mentioned included angle can be designed according to the needs, and can be designed in the interval of 5-45 degrees (it is better to say "0-45 degrees"), or a series can be set according to the needs, such as every 5 degrees or 10 degrees for a series, etc. , to suit different needs.

[0023] The material of the above-mentioned gasket body can be various existing gaskets, such as various rubber gaskets, metal gaskets and the like. For the gasket with a large angle, in order to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com