Air nozzle assembly having a joining apparatus

A nozzle and air flow technology, applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve the problem of very strict manufacturing process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

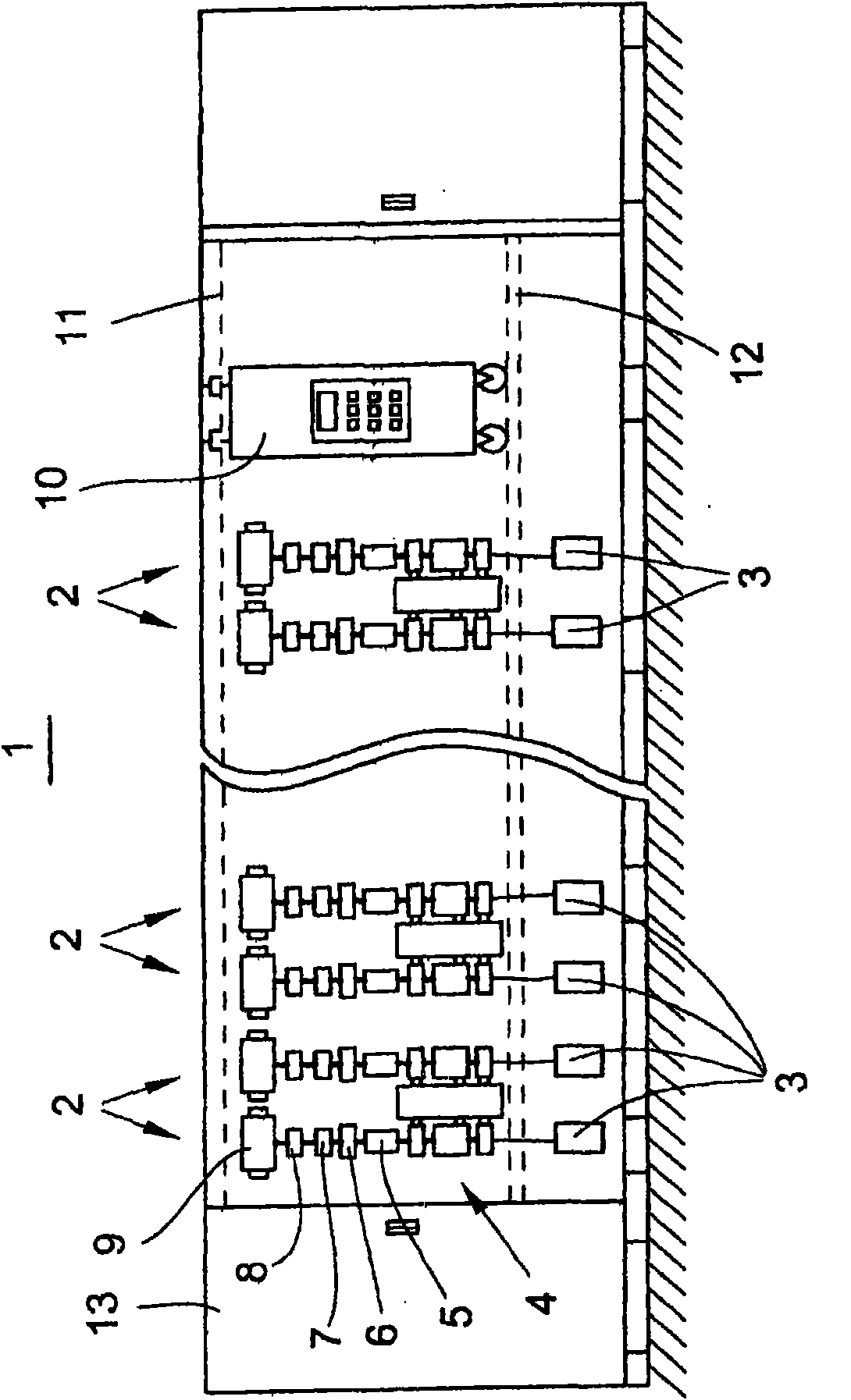

[0020] figure 1 The air spinning machine 1 shown in front view in FIG. 2 has a plurality of work stations 2 arranged next to each other and a drive unit 13 at at least one end of the air spinning machine.

[0021] Each spinning station 2 of an air spinning machine has, for example, a sliver source for a spinning cylinder 3, a drafting device 4, an air spinning device 5, a yarn take-off device 6, a yarn clearer 7 and a yarn traverse device 8. The yarn traversing device 8 is responsible for winding the yarn produced in the air spinning device 5 onto the winding bobbin 9 in a manner that the layers cross each other. The cross-wound bobbin 9 is held in the creel and driven in rotation by the bobbin drive.

[0022] figure 1 Also shown, the automatically working service unit 10 Serving the spinning stations 2 of the air spinning machine 1 , the service unit 10 is guided on guide rails 11 , 12 and can be moved along these spinning stations 2 .

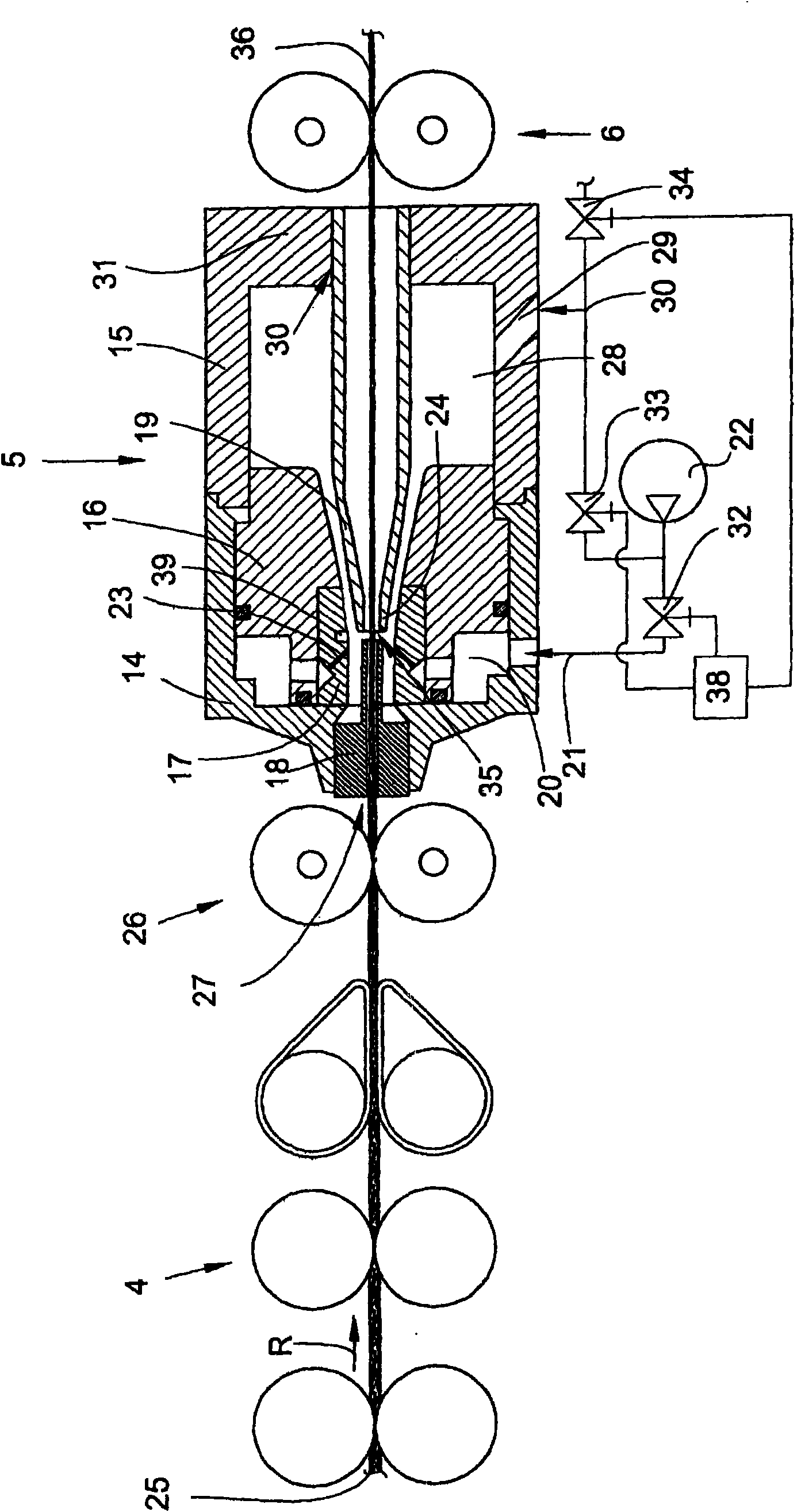

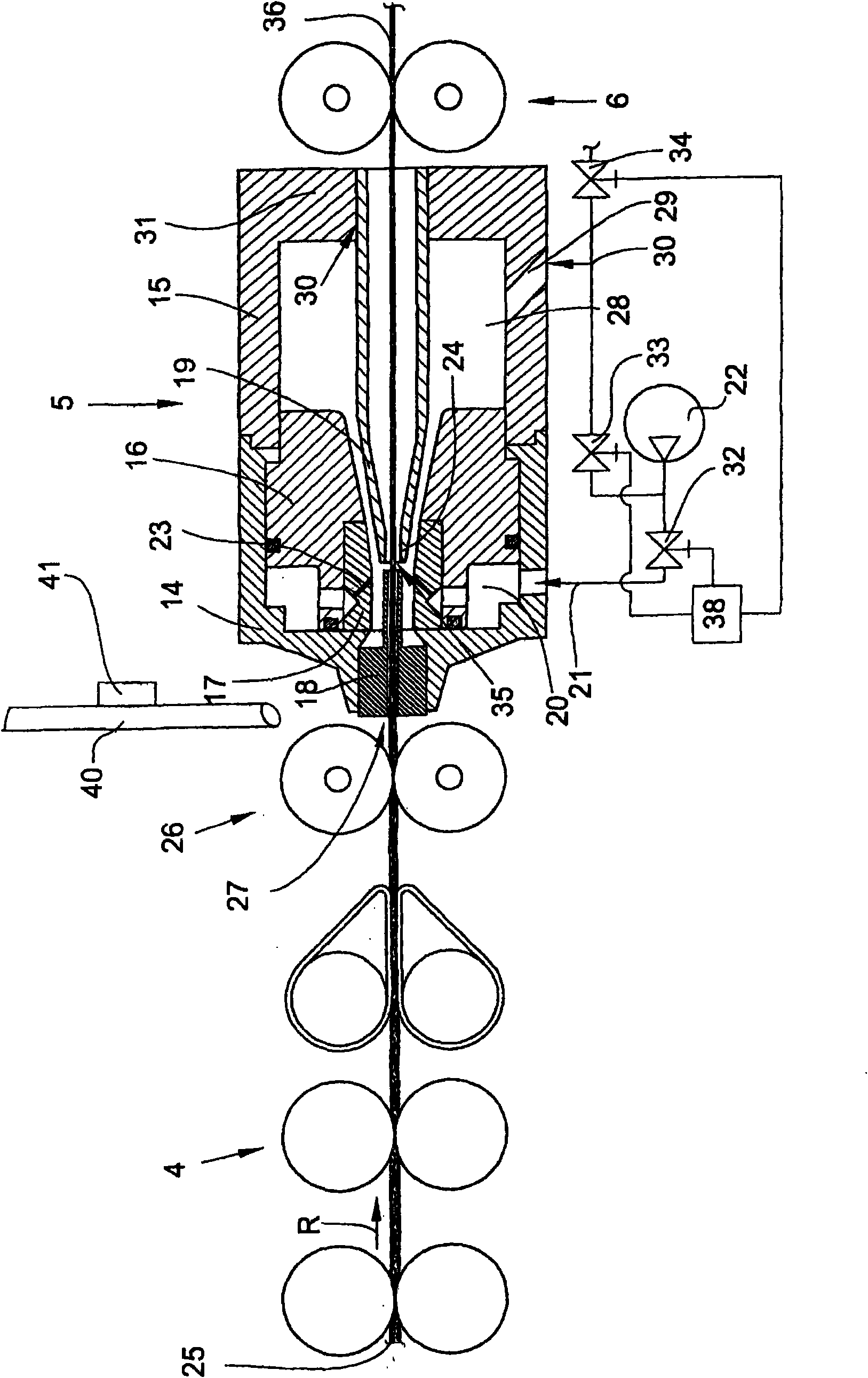

[0023] figure 2 Shown schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com