Thermal fusing sealing process of metal-glass solar heat-collecting tube

A technology of vacuum heat collecting tubes and solar energy, applied in the direction of solar heat collectors, fixed bases/supports of solar heat collectors, solar thermal energy, etc., can solve the problems of temperature limitation and low melting point, and achieve fusion sealing strength and tensile strength Good strength, simplified process, and reduced irregularity of hot-melt cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

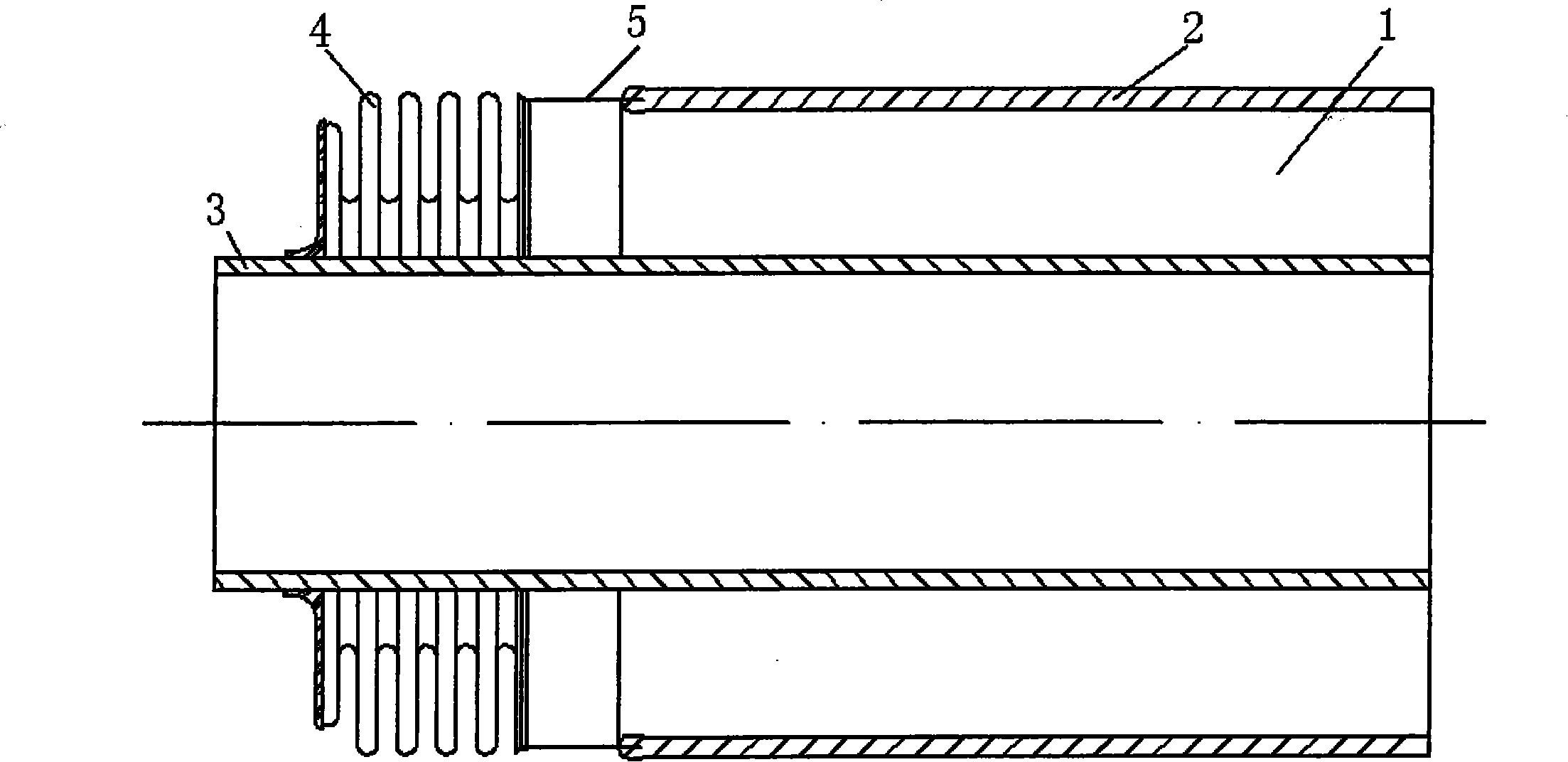

[0035] Such as figure 2As shown, the diameter of the glass tube 2 in this embodiment is 60 mm, the wall thickness is 2 mm, and the length is 1000 mm. The transition metal pipe 5 is a straight pipe made of 4J33 iron-nickel-cobalt alloy, and the wall thickness D is 0.3mm. First place the transition metal tube 5 under the glass tube 2 and align it coaxially; use high-frequency electromagnetic induction heating equipment to perform pre-oxidation treatment on the fusion seal of the transition metal tube 5 in air at a temperature of 1050°C for 1 minute Then the glass tube 2 lower end face is in positive contact with the transition metal tube 5 upper end face, and the transition metal tube is continued to be heated, and the glass tube 2 is heated through the transition metal tube 5; after the glass tube 2 lower end contact part is softened or melted, apply Slowly insert the transition metal tube 5 into the wall of the glass tube 2 with an appropriate pressure, and the depth L of th...

Embodiment 2

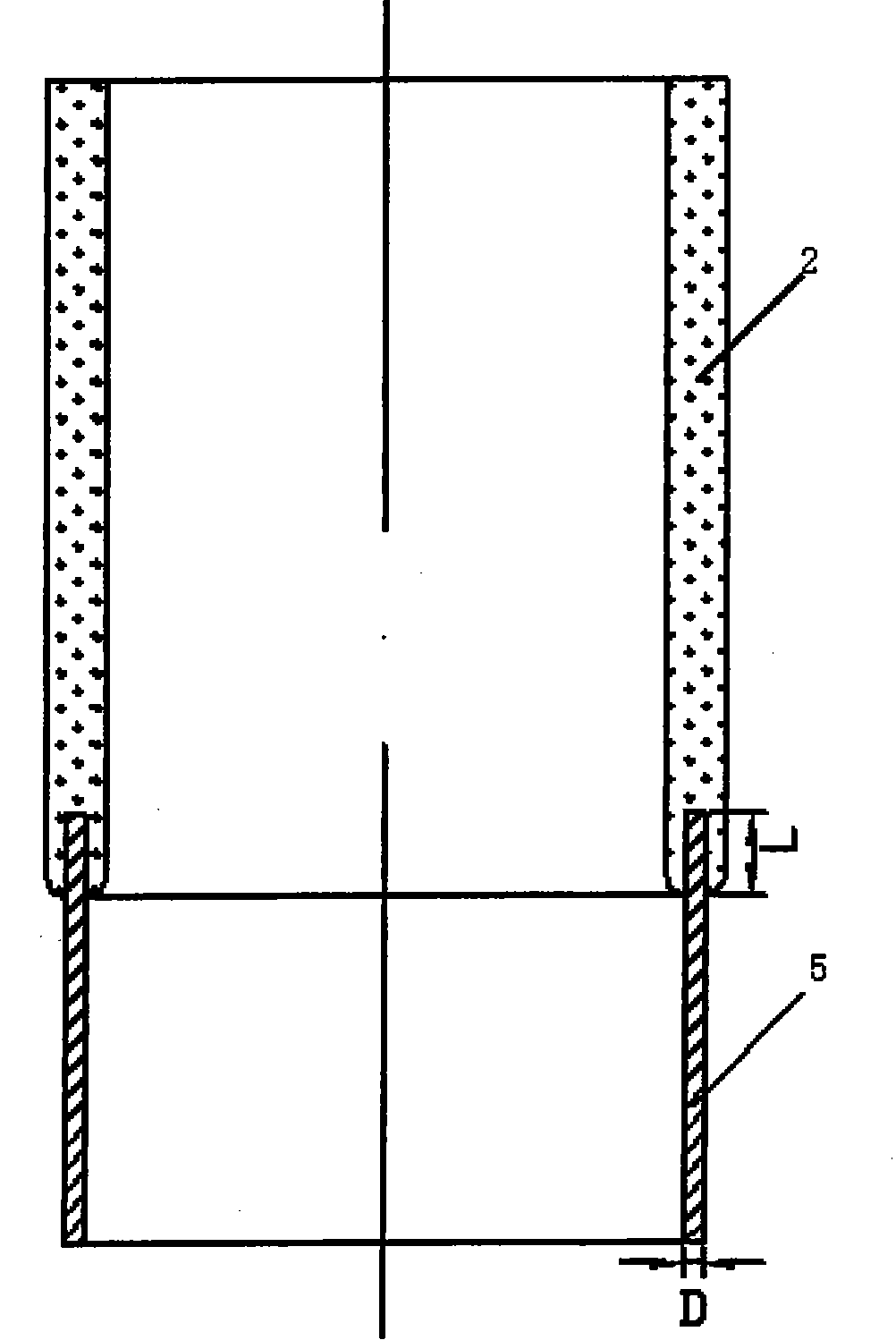

[0037] Such as image 3 As shown, the outer diameter of the glass tube 2 in this embodiment is 120 mm, the wall thickness is 3 mm, and the length is 250 mm. The transition metal tube 5 has an L-shaped outer flange 6 structure, the material is 4J29 iron-nickel-cobalt alloy, and the wall thickness is 1mm. First place the transition metal tube 5 under the glass tube 2 and align it coaxially; use high-frequency electromagnetic induction heating equipment to pre-oxidize the fusion seal of the transition metal tube 5 in air at a temperature of 950°C for 3 minutes Then the glass tube 2 lower end face is in direct contact with the transition metal tube 5 upper end, utilizes high-frequency electromagnetic induction heating equipment to continue heating the transition metal tube, and the glass tube 2 lower end is heated by the transition metal tube 5, and the glass tube 2 lower end is heated. After the contact part is softened or melted, apply appropriate pressure to slowly insert the ...

Embodiment 3

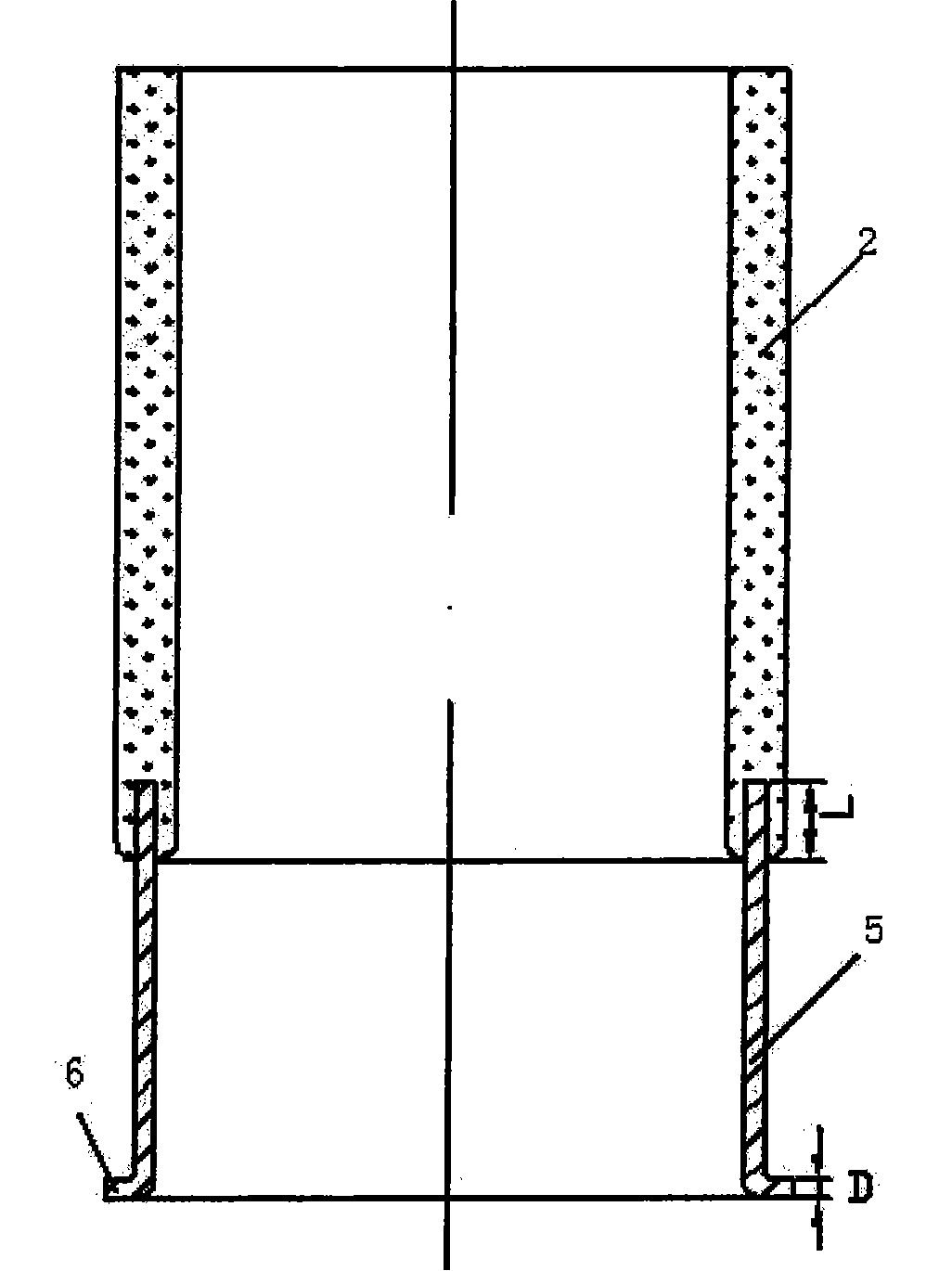

[0039] Such as Figure 4 As shown, the diameter of the glass tube 2 in this embodiment is 104 mm, the wall thickness is 2.8 mm, and the length is 2000 mm. The transition metal tube 5 has an outer annular step 7, which is made of 4J44 iron-nickel-cobalt alloy, and the wall thickness D is 0.8mm. First place the transition metal tube 5 under the glass tube 2 and align it coaxially; use high-frequency electromagnetic induction heating equipment to pre-oxidize the fusion seal of the transition metal tube 5 in air at a temperature of 800°C for 15 minutes ; Then the glass tube 2 lower end face is in direct contact with the transition metal tube 5 upper end face, utilizes the high-frequency electromagnetic induction heating equipment to continue heating the transition metal tube, and the glass tube 2 is heated by the transition metal tube 5; After the contact part is softened or melted, an appropriate pressure is applied to slowly insert the transition metal tube 5 into the wall of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com